Minitype flue gas waste heat recovery and storage integrated hot water supply device

A flue gas waste heat and hot water supply technology, which is applied to furnaces/stoves with hot water devices, applications, household heating, etc., can solve problems such as poor comfort, hot water system cannot circulate normally, and high exhaust temperature , to achieve the effect of constant room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

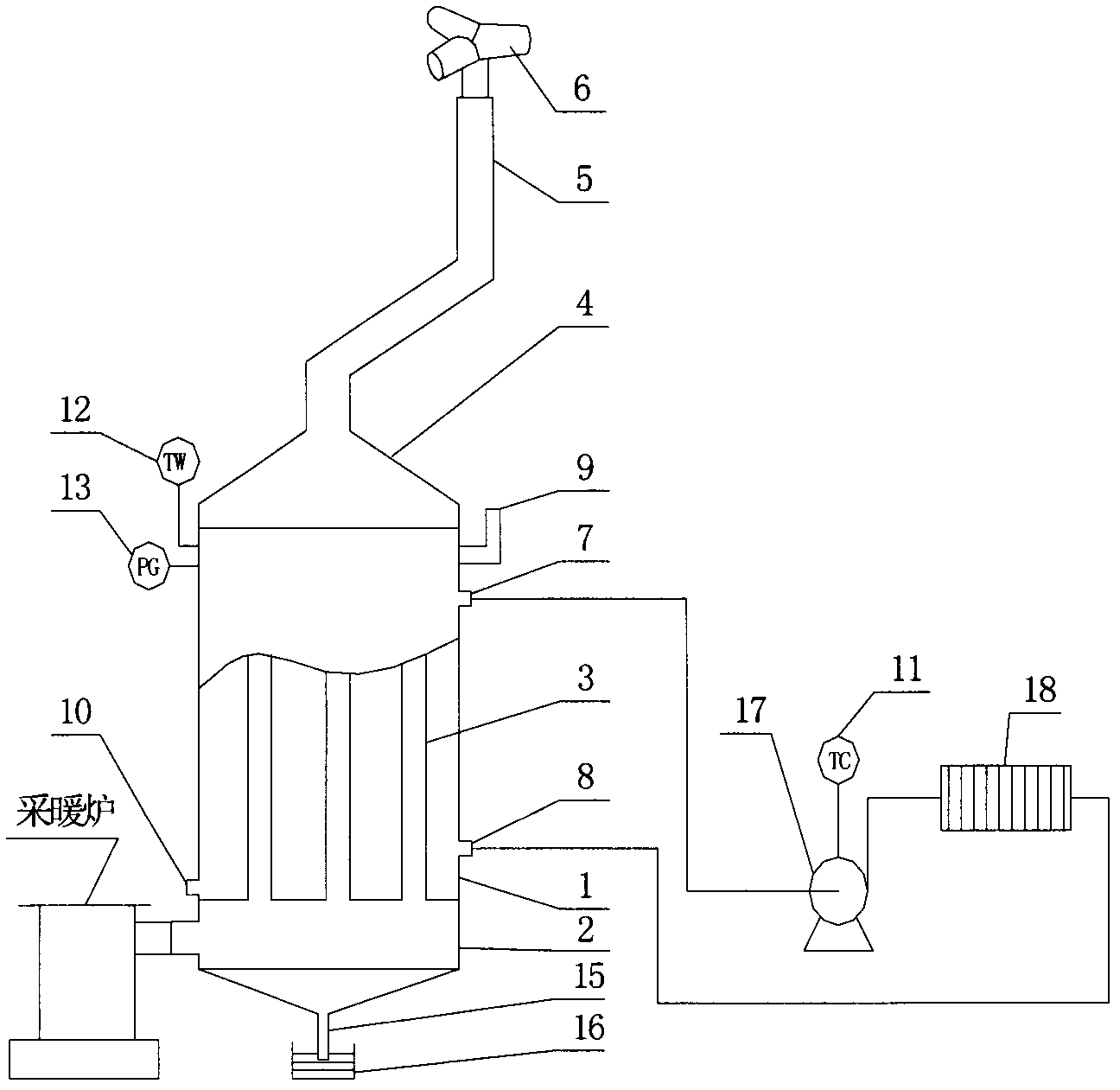

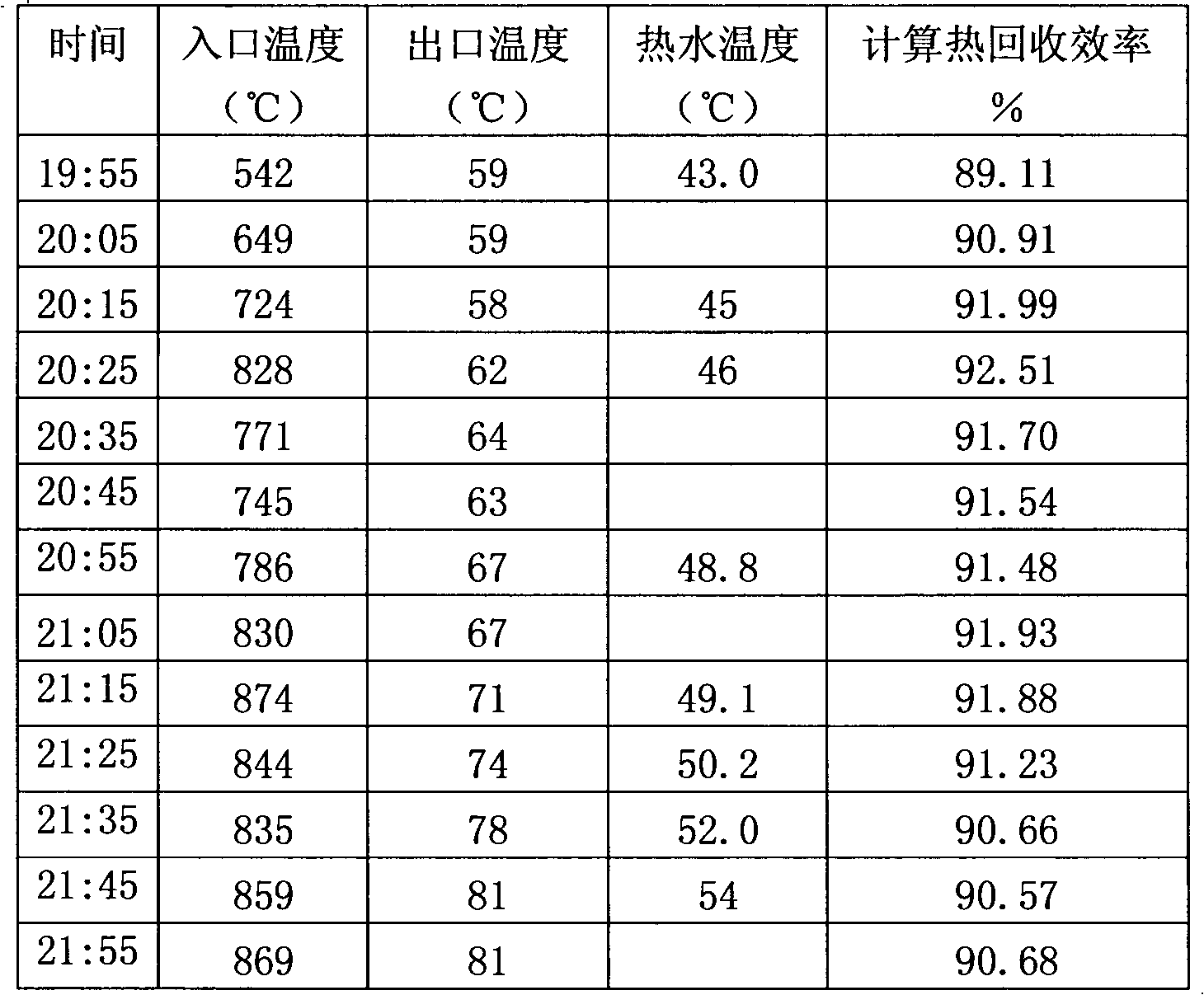

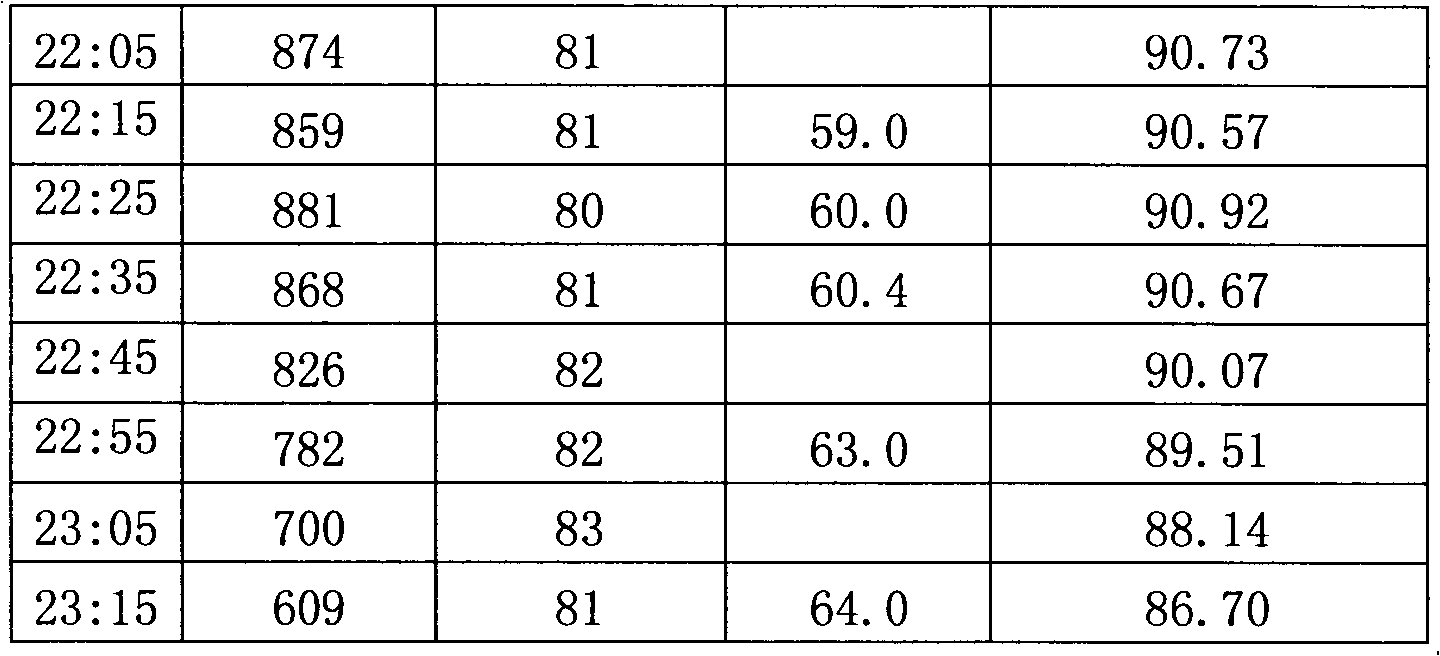

[0048] In a heating area of 30m 2 , average heat supply 50W / m 2 , in the small flue gas waste heat recovery and heat storage integrated hot water supply device that burns coal once a day, a set of devices as shown in the accompanying drawings is installed. The specific operation process and effects are described as follows:

[0049] Heat storage water tank 1 volume is O.544m 3 , the water capacity is about 520kg, and the heat exchange area of the smoke pipe 3 in the heat storage water tank is about 3.6m 2 , a small heating furnace with a coal loading capacity of 8kg at a time, and the calorific value of coal is 5000kcal / kg. The stored water enters the upper smoke box 4 after the temperature drops to 50-120° C. after heat exchange, and then is discharged into the atmosphere through the chimney 5 and the tobacco pipe 6 in sequence. The hot water heated up to 40-95°C in the heat storage water tank 1 after exchanging heat with the flue gas returns to the heat storage water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com