Low-power-consumption and high-precision ultrasonic flow rate measuring method and device

A flow measurement and ultrasonic technology, which is applied in the field of low power consumption and high precision ultrasonic flow measurement methods and devices, can solve the problems of difficulty in meeting field requirements, increased power consumption of the device, and low repeatability, and achieves cost saving and reduction. The effect of low power consumption and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

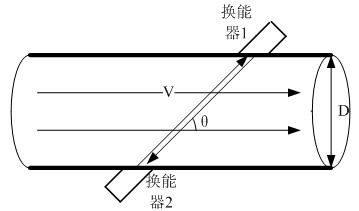

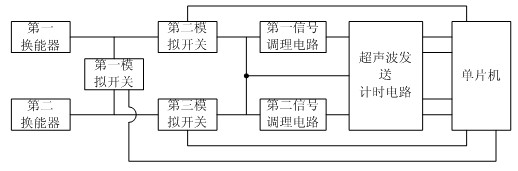

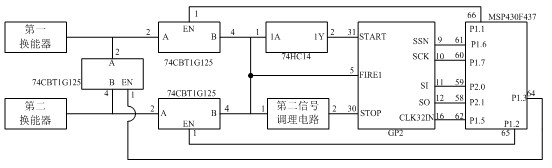

[0022] Further illustrate the present invention below in conjunction with accompanying drawing.

[0023] refer to figure 2 , the low-power-consumption and high-precision ultrasonic flow measurement device includes a first transducer, a second transducer, a first analog switch, a second analog switch, a third analog switch, a first signal conditioning circuit, and a second signal conditioning circuit , Ultrasonic sending timing circuit and single chip microcomputer.

[0024] The input end of the first transducer is respectively connected to one end of the first analog switch and one end of the second analog switch; the input end of the second transducer is respectively connected to one end of the first analog switch and one end of the third analog switch;

[0025] The other end of the second analog switch, the other end of the third analog switch, the input end of the first signal conditioning circuit and the input end of the second signal conditioning circuit are all connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com