Heliostat device and corresponding heliostat system

A technology for heliostats and mirror frames, applied in the field of heliostat systems and heliostat devices, can solve the problems of high calibration and maintenance costs, large mirror surface deformation errors, high cost, etc., to improve the problem of shaft deformation and improve Reliability, the effect of reducing manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

[0042] First introduce the explanation of the technical terms involved in the present invention:

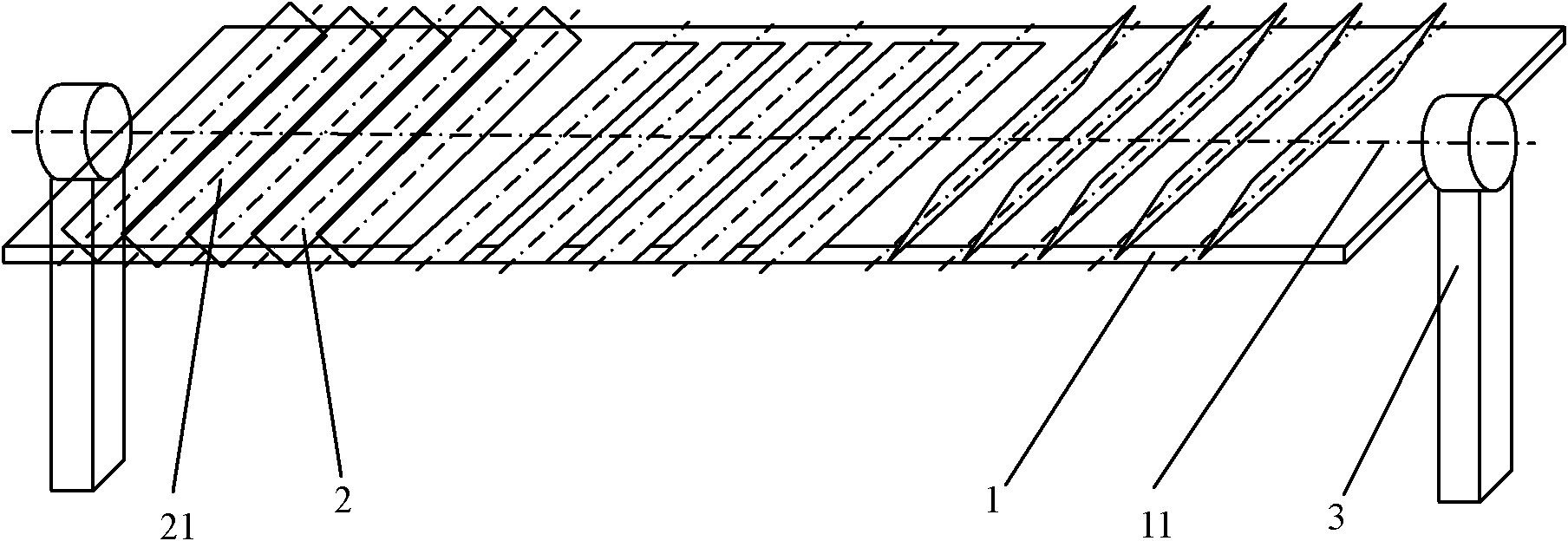

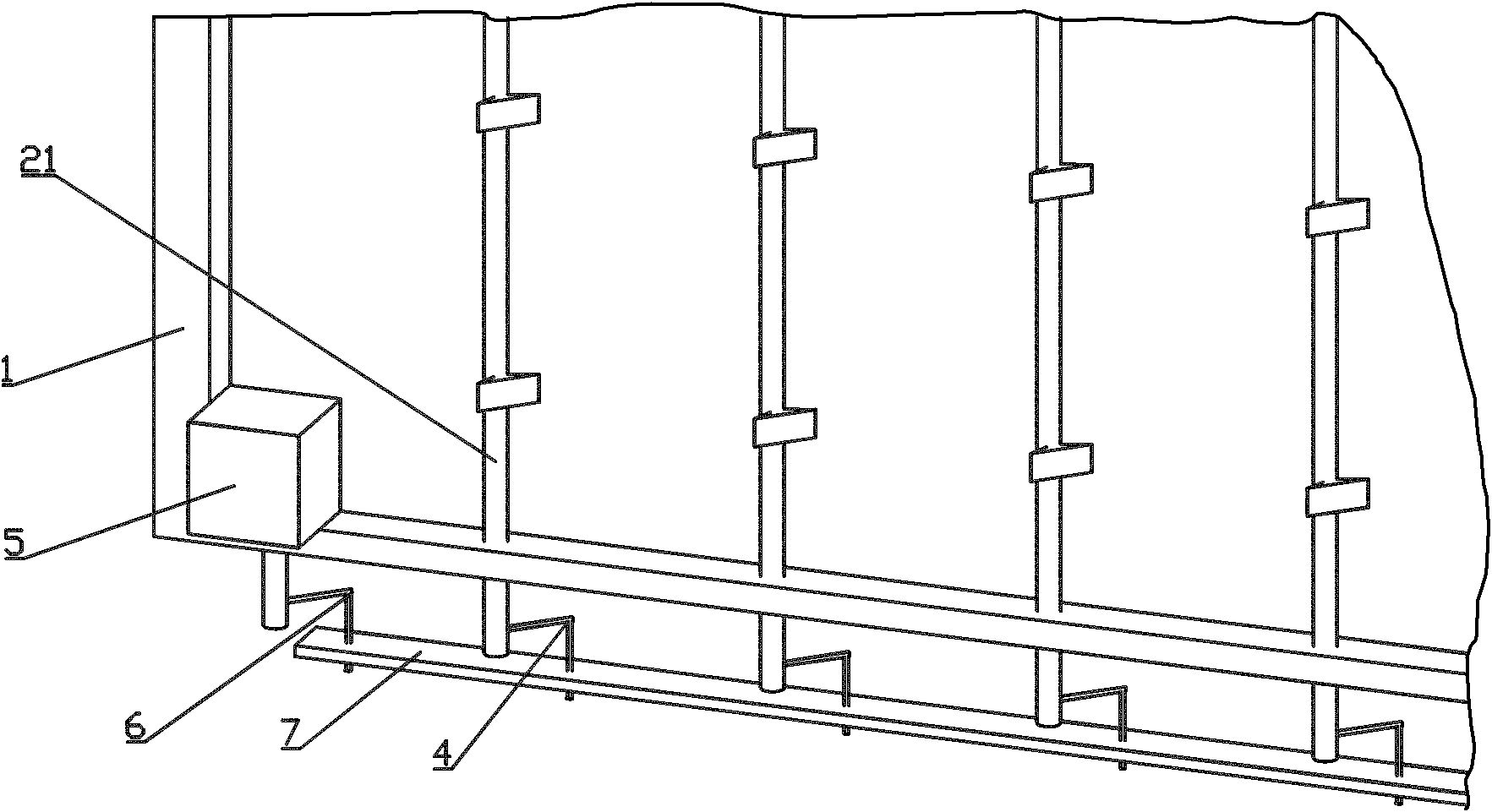

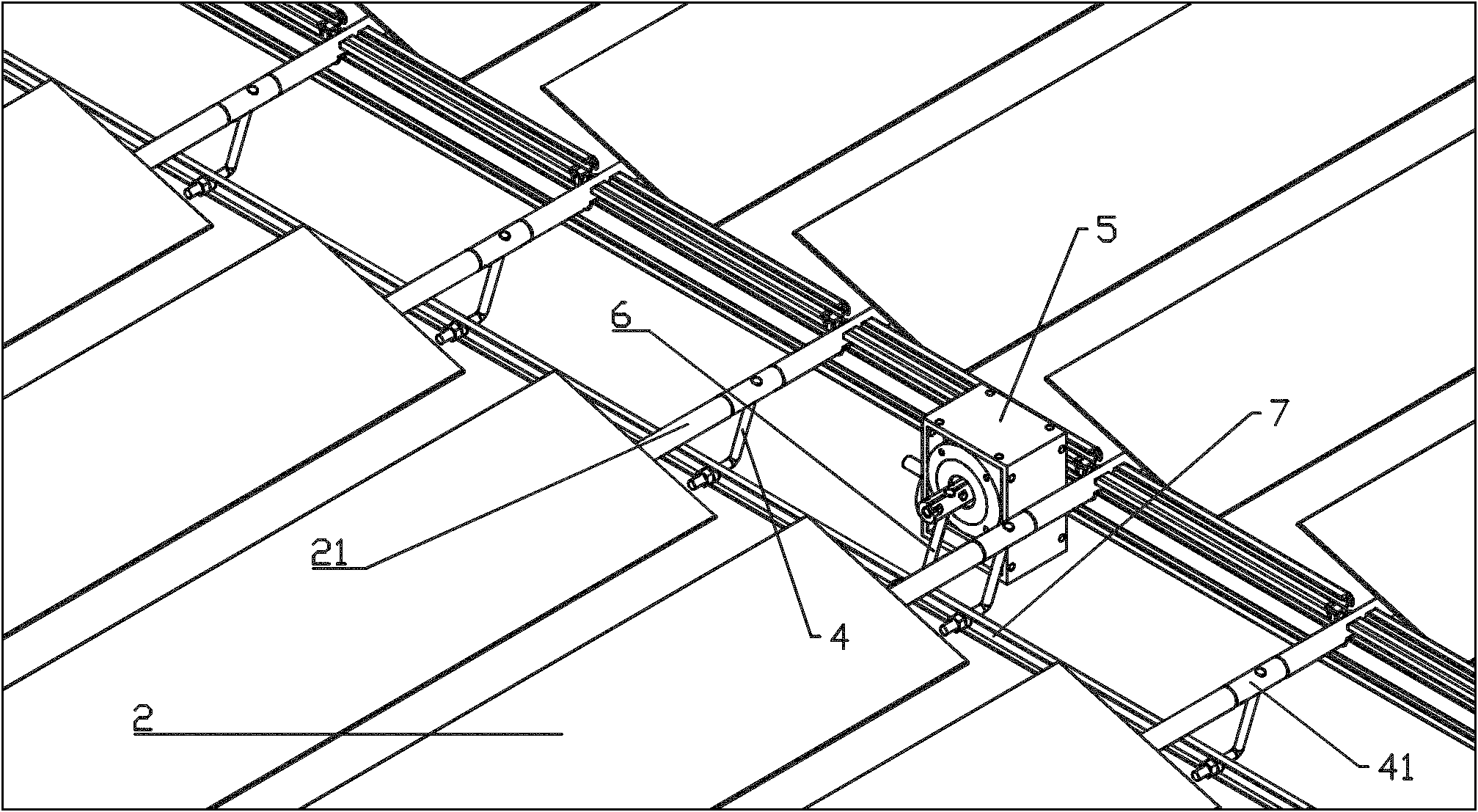

[0043] Heliostats: Devices that reflect sunlight used in solar thermal power generation

[0044] Sub-mirror: a small mirror in a heliostat unit

[0045] ●Rolling angle: the rotation angle of the frame of the whole heliostat unit

[0046] Roll axis: the rotation axis of the whole heliostat unit frame

[0047] ●Bracket: the support structure between the two ends of the rolling shaft of the heliostat unit frame and the ground

[0048] ●Elevation angle: the rotation angle of the sub-mirror relative to the heliostat frame

[0049] ●Pitch axis: the rotation axis of each sub-mirror

[0050] Angle difference: preset fixed pitch angle difference between sub-mirrors

[0051] The technical problem that the present invention mainly aims at solving mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com