Electronic tag

A technology of electronic tags and substrates, which is applied in the field of radio frequency identification, can solve problems such as poor adaptability of background materials, difficult realization of manufacturing process, and influence on application range, etc., and achieve the effect of maintaining radiation performance, reducing size, and expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

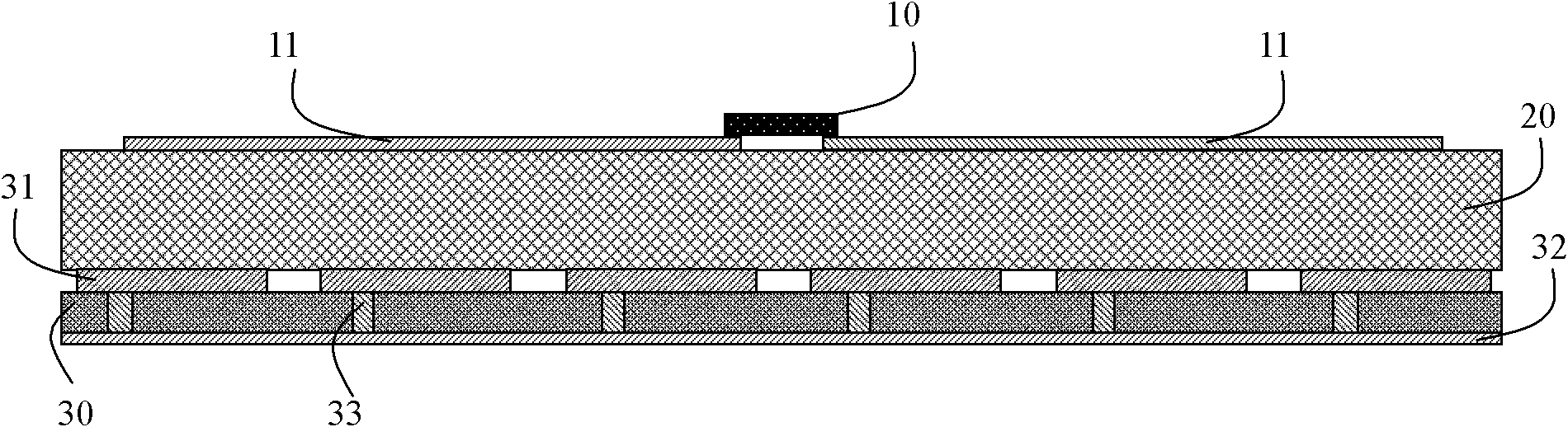

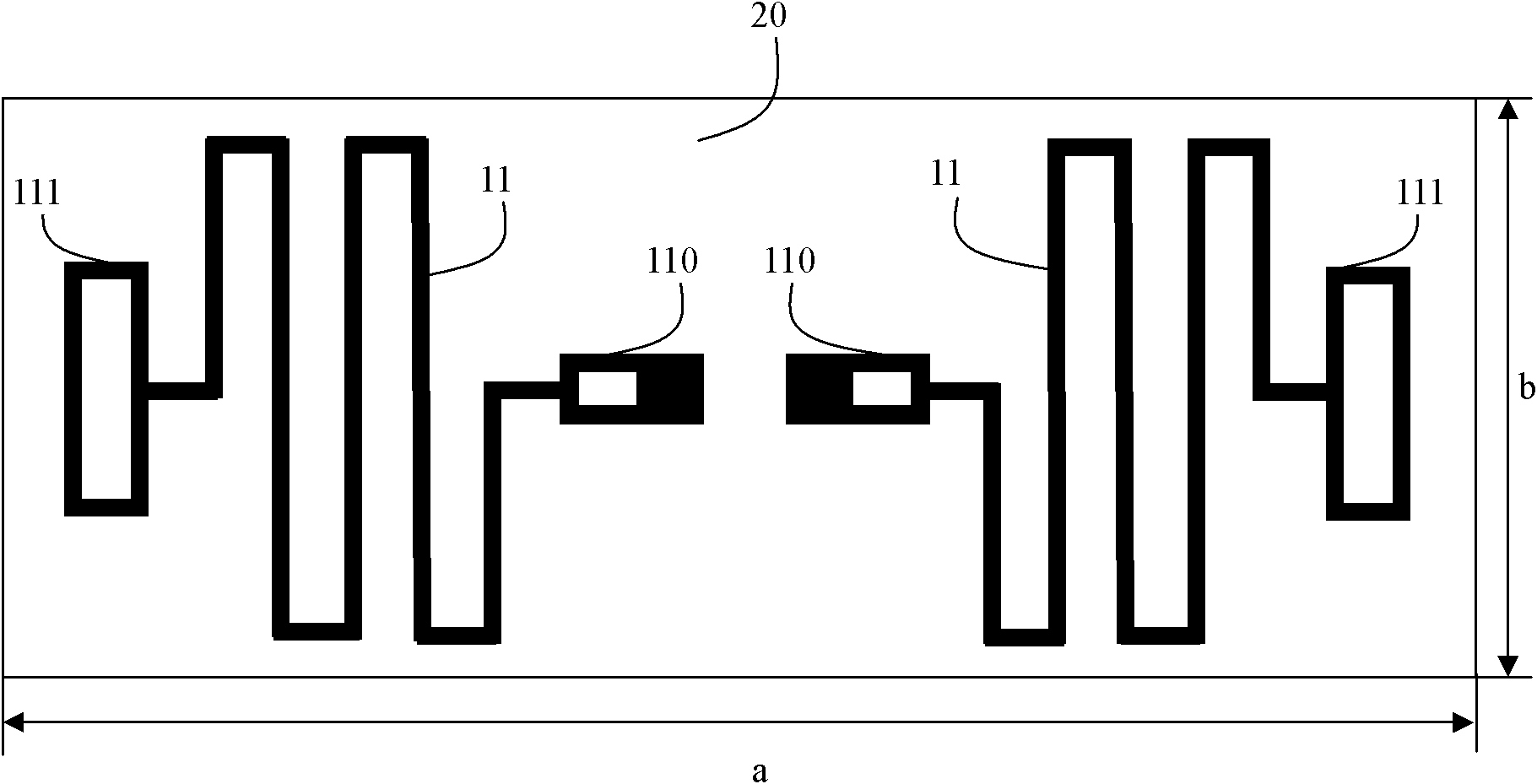

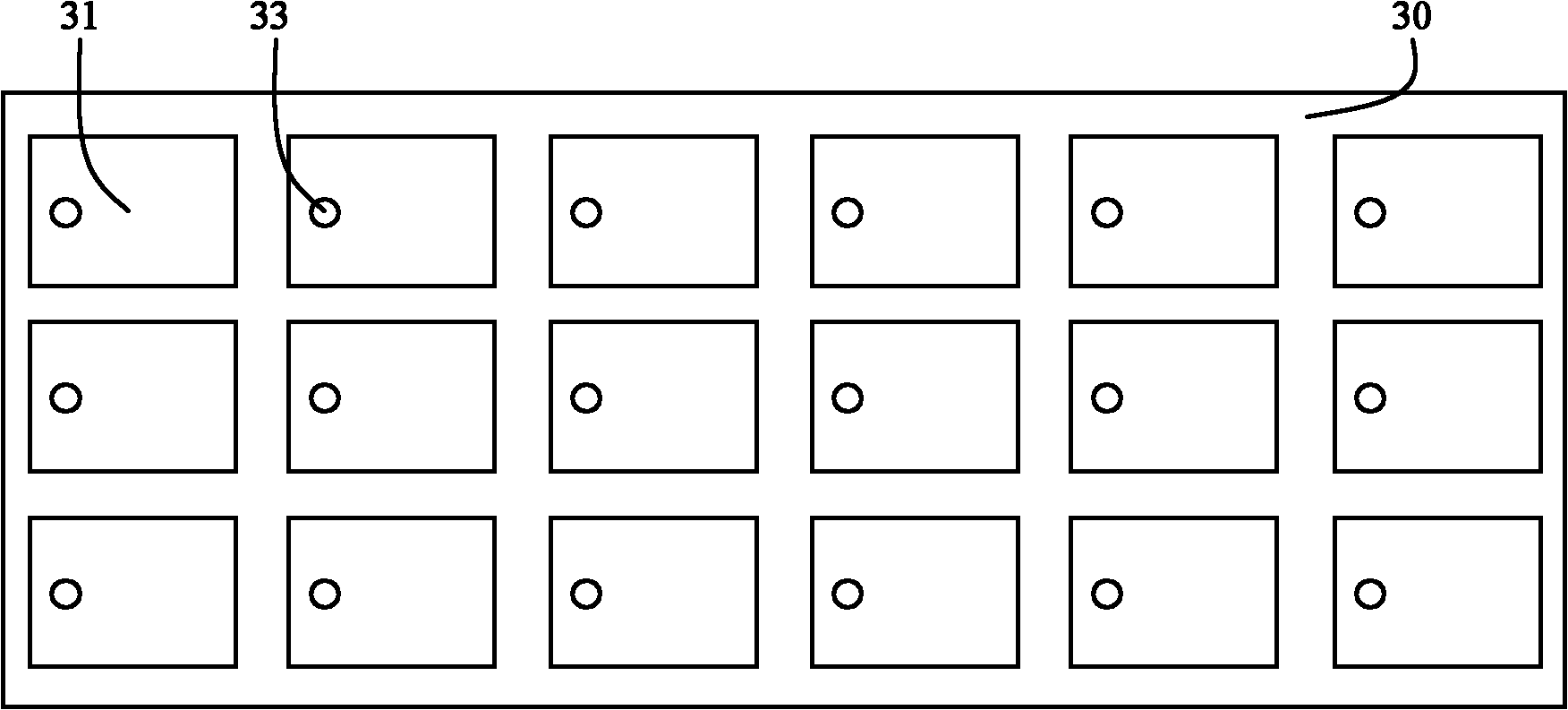

[0025] In this example, the electronic tag includes a substrate and a microstrip antenna. see figure 1 , figure 2 , image 3 and Figure 4 In this example, the substrate is composed of a support layer 20 , a metal patch layer 31 , a dielectric layer 30 and a metal ground 32 . Here, the metal patch layer 31 , the dielectric layer 30 and the metal ground 32 constitute the structure of the AMC. The specific manufacturing process is to form a metal film on the front and back of the dielectric layer. The material of the metal film used in this example is copper. The metal film on the front side of the dielectric layer 30 is etched to form metal sheets isolated from each other, forming the metal patch layer 31 ; an integral metal film on the back side of the dielectric layer forms the metal ground 32 . The metal patch layer can also be formed by pasting a rectangular metal sheet on the front of the dielectric layer 30 . In the AMC ground structure, each metal sheet on the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com