Two-in-one coaxial direct current brushless motor

A DC brushless and motor technology, which is applied in the field of high-efficiency motors and two-in-one coaxial DC brushless motors, can solve problems such as dead angles still exist, large circuit space, and difficulty in starting, so as to simplify the parts and assembly process and facilitate processing Production, the effect of compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

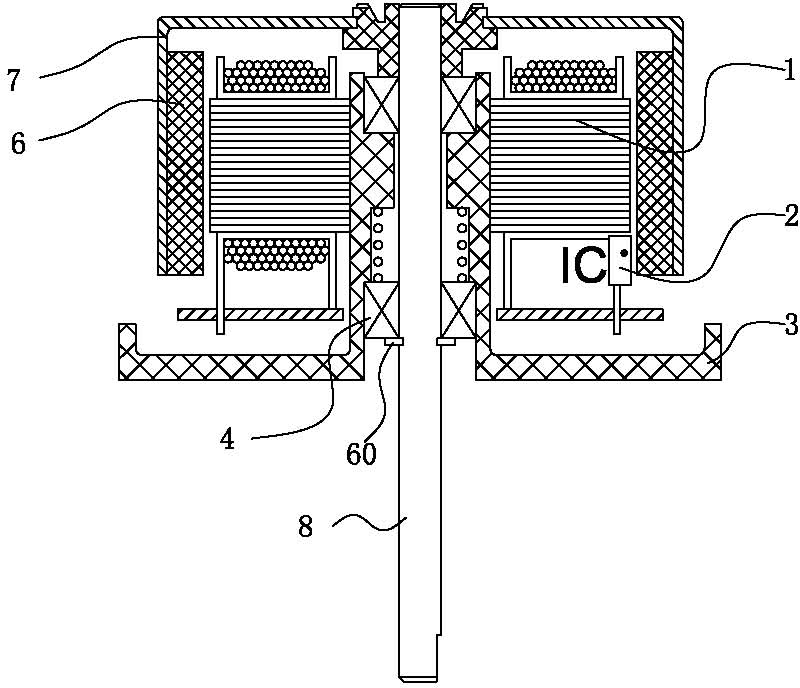

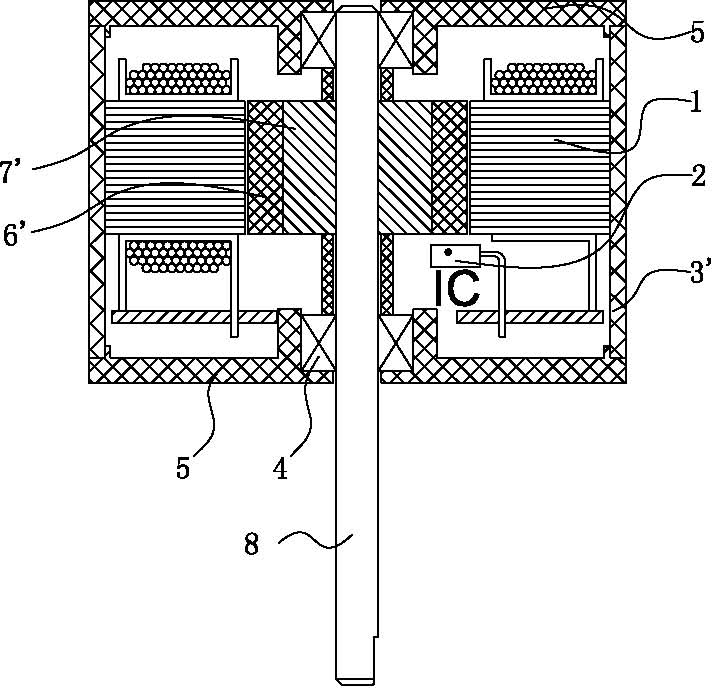

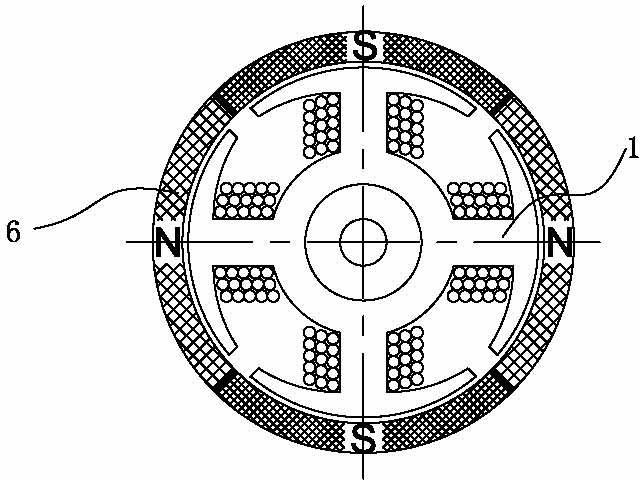

[0060] See Figure 5 to Figure 1 5, which shows the specific structure of the preferred embodiment of the present invention, including a common shaft 10, the first motor and the second motor coaxial (see Figure 5 or Figure 7 or Figure 14 ), the first motor and the second motor are both outer rotor brushless DC motors or inner rotor brushless DC motors, the output torque directions of the first motor and the second motor are the same, and the magnetic field polarity of the first rotor The relative phase of the midpoint and the midpoint of the first stator polarity teeth in radial projection is misaligned with respect to the relative phase of the radial projection of the second rotor's magnetic field polarity midpoint and the second stator polarity tooth midpoint, The misalignment angle is equal to 180° / number of stator teeth (see Figure 10a and Figure 10b shown or Figure 15a and Figure 15b shown);

[0061] Such as Figure 5 and Figure 6 As shown, it is the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com