Electrical discharge machining (EDM) method of super-hard micro-hemisphere couple part

A processing method and electric spark technology, applied in electric processing equipment, metal processing equipment, electrode manufacturing and other directions, can solve the problems of high machine tool requirements, grinding wheel wear, long processing time, etc., to improve processing efficiency, reduce electrode loss, reduce The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

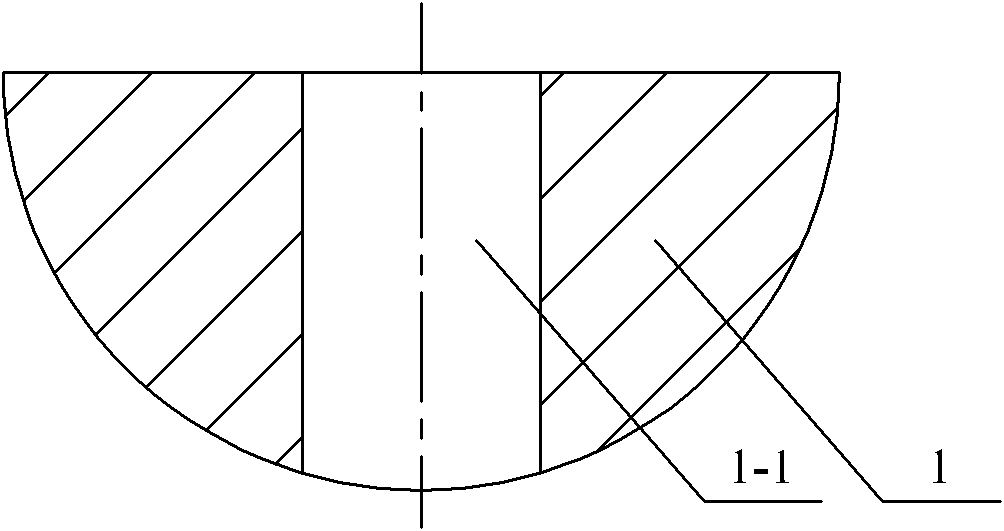

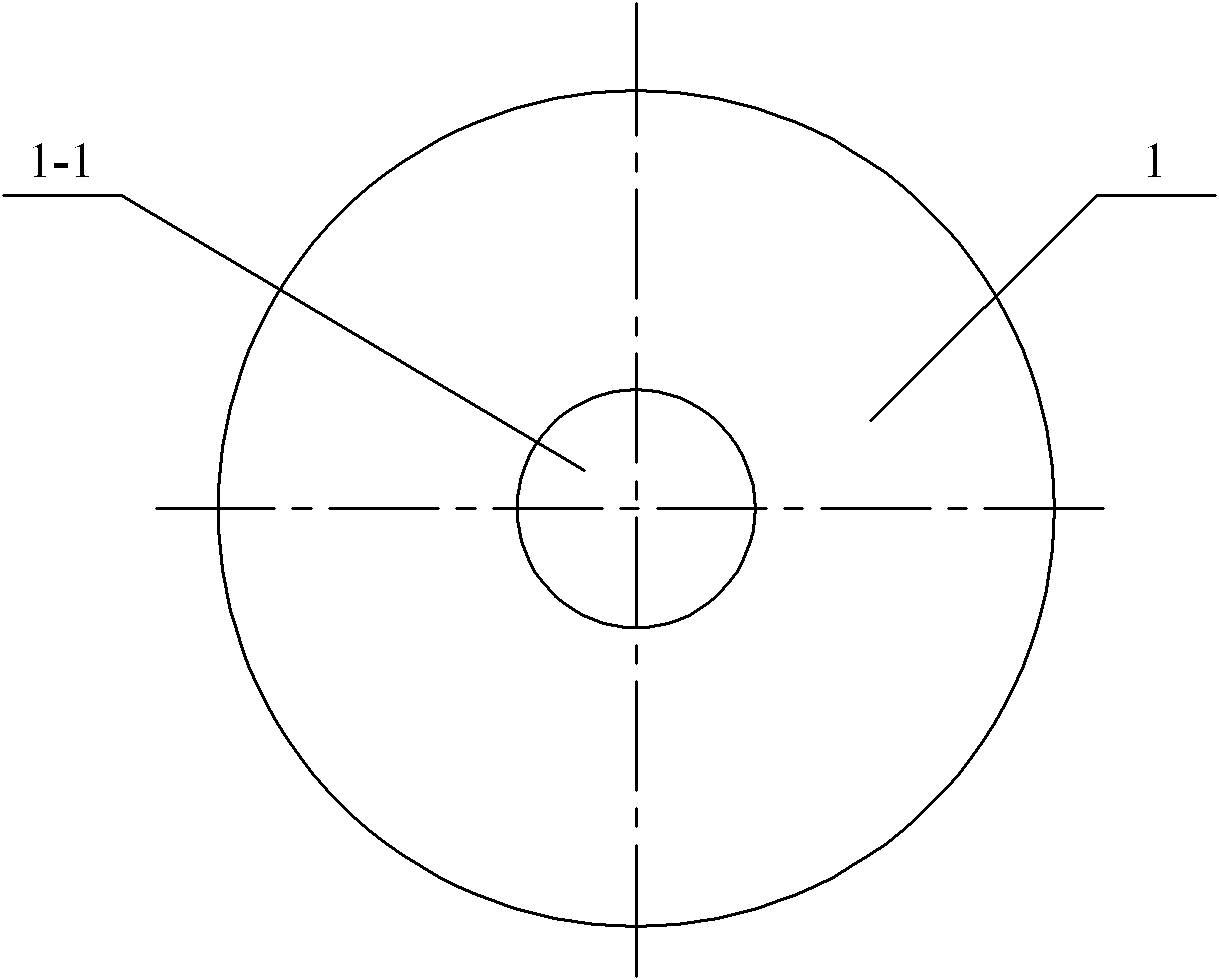

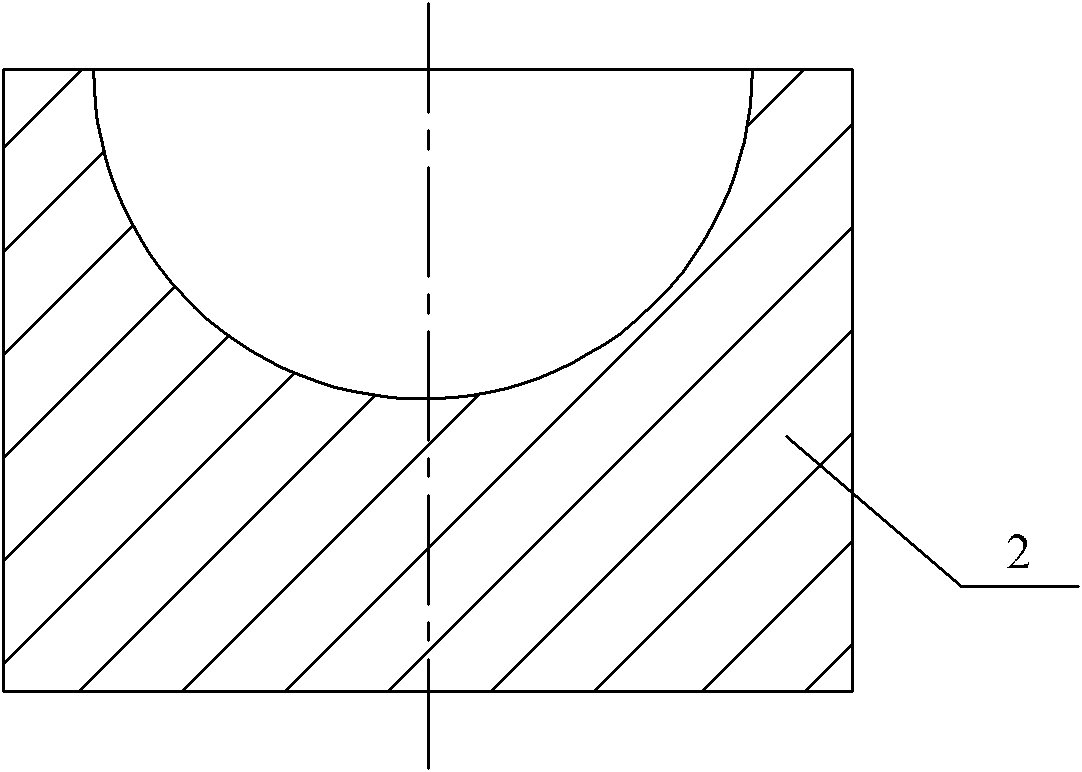

[0015] Specific implementation mode one: combine Figure 1 to Figure 12 Illustrate, the electrical discharge machining method of superhard micro hemispherical couple of this embodiment, described superhard micro hemispherical couple comprises two workpieces, and described two workpieces are respectively convex spherical hemispherical workpiece 1 and concave spherical hemispherical workpiece 2, The hardness HRC of the superhard micro hemispherical couple is 92-93; the electric discharge machining method is completed by the following steps:

[0016] Step 1: Design two electrodes (in order to obtain the required dimensional accuracy, shape accuracy and high processing efficiency, in EDM, it is necessary to scientifically design the electrodes and control the processing process. The size of the electrodes will be directly affect the final machining shape of the workpiece, and the process determines the machining efficiency and machining surface quality); the two electrodes are the...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination Figure 9 and Figure 10 Explain that the concave spherical surface diameter of the concave spherical surface electrode 3 in step one of the present embodiment is 50 μm larger than the target machining diameter of the convex spherical surface hemispherical workpiece 1, and the concave spherical surface error of the concave spherical surface electrode 3 is 20 μm; the convex spherical surface diameter of the convex spherical surface electrode 4 It is 50 μm smaller than the target machining diameter of the concave spherical hemispherical workpiece 2 , and the convex spherical error of the convex spherical electrode 4 is 20 μm. The workpiece can obtain better surface precision, the peak-to-valley value (PV value) of the surface shape precision is about 2 μm, and the roughness of the processed surface is about 0.6 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 9 and Figure 10 Explain that in step 3 of the present embodiment, the convex spherical hemispherical workpiece 1 starts to move, and the peak current of the electric discharge machining starts when it contacts the concave spherical electrode 3. The peak current is 20A, the pulse width is 50 μs, and the pulse interval is 100 μs; The peak current of electric discharge machining for concave spherical hemispherical workpiece 2 is 20A, the pulse width is 50 μs, and the pulse interval is 100 μs. The workpiece can obtain better surface precision, the peak-to-valley value (PV value) of the surface shape precision is about 2 μm, and the roughness of the processed surface is about 0.6 μm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com