Traceless laser correction method for back deformation of stainless steel plate subjected to non-penetration laser welding

A technology of laser welding and stainless steel plate, which is applied in the field of laser heat treatment, to avoid discoloration and restore smoothness on the back surface of the outer plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

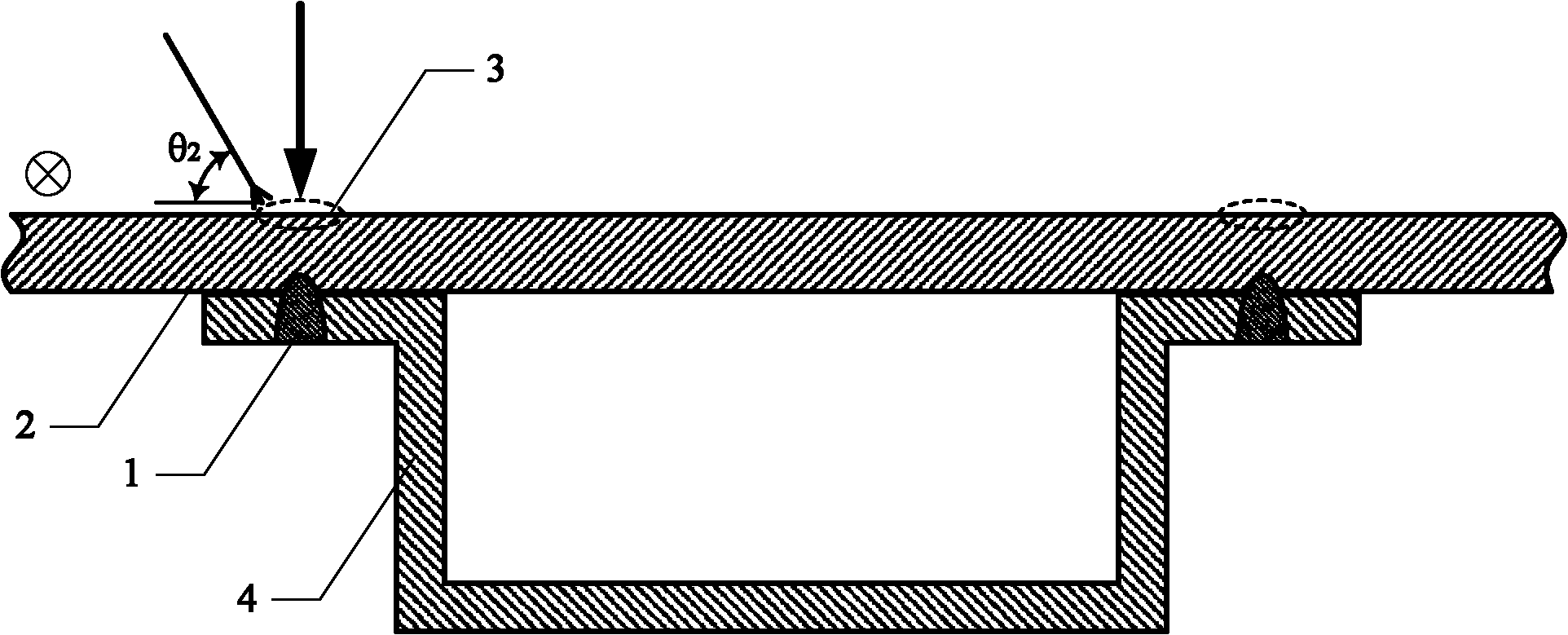

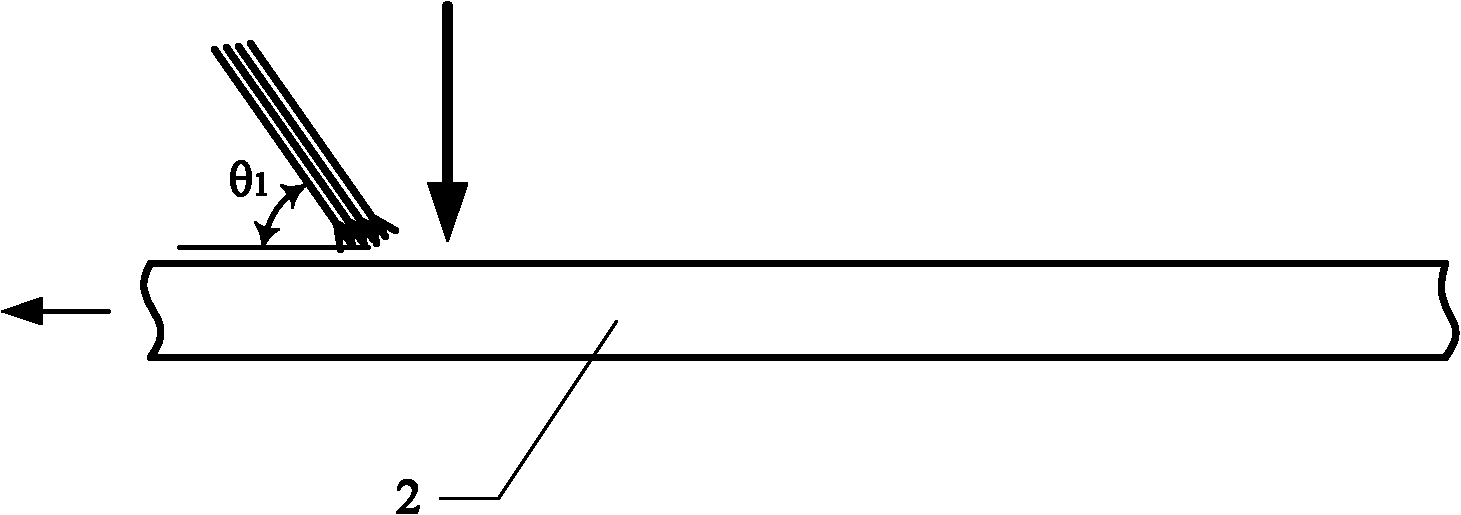

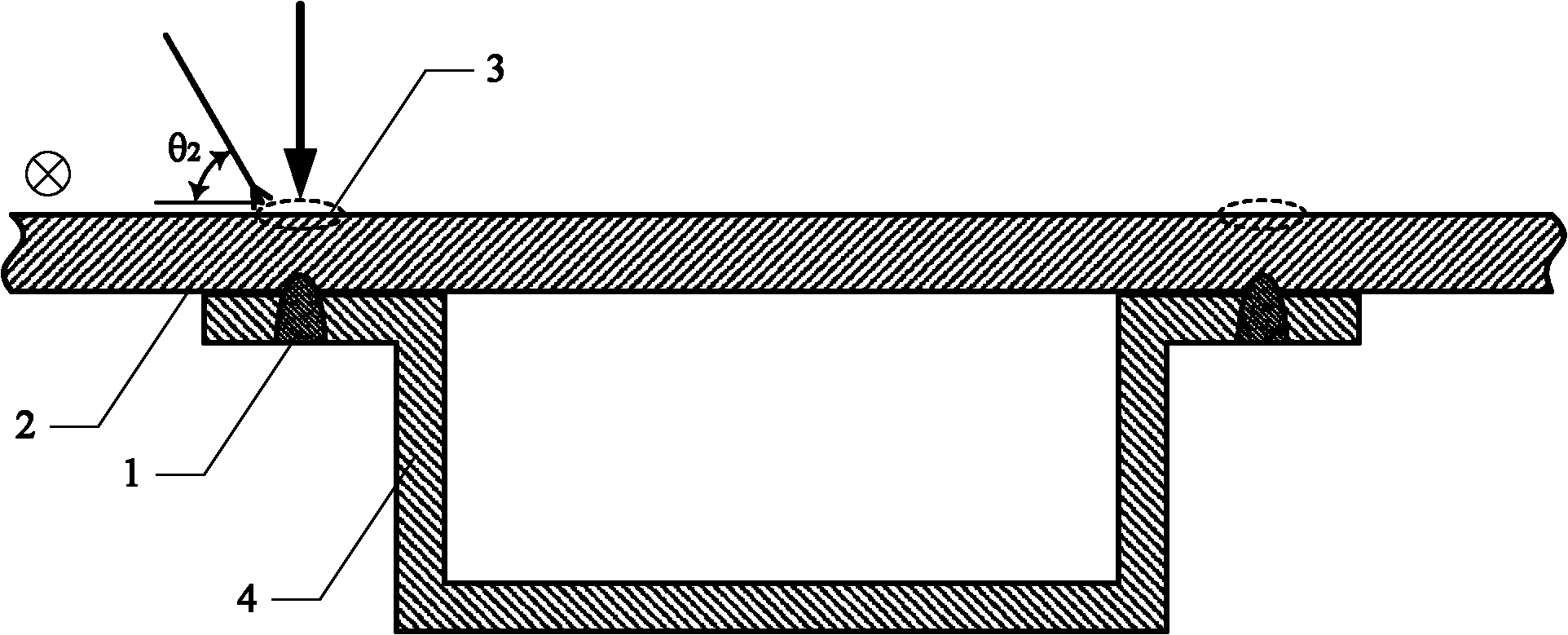

[0010] Clean the deformed area 3 on the back of the stainless steel body panel 2 of the rail passenger car with acetone to remove surface oil. The outer plate 2 and the outer plate reinforcing member 4 are made of SUS301L cold-rolled stainless steel plate, the thickness of the outer plate 2 is 1.5mm, the thickness of the outer plate reinforcing member 4 is 0.8mm, and the penetration depth is 1.0mm. See figure 1 , figure 2 shown, with quasi-fundamental CO 2 The laser is the heat source, the laser power is 80W, and the defocus is +4mm. Move and heat the deformed area 3 on the back of the stainless steel car body panel 2 of the rail car along the direction of the weld 1 at a moving speed of 0.5m / min. Blow protective gas N into the heated area at the same time 2 . The protective gas is blown in after the laser heating; the protective gas is composed of 4 parallel airflows arranged in a line along the laser heating moving direction; the protective gas blowing direction and th...

Embodiment 2

[0012] Clean the deformed area 3 on the back of the stainless steel body panel 2 of the rail passenger car with acetone to remove surface oil. The outer plate 2 and the outer plate reinforcement member 4 are made of SUS304 cold-rolled stainless steel plate, the thickness of the outer plate 2 is 2.0mm, the thickness of the outer plate reinforcement member 4 is 1.0mm, and the penetration depth is 1.2mm. See figure 1 , figure 2 As shown, the fundamental mode YAG laser is used as the heat source, the laser power is 100W, and the defocus amount is +2mm. Move and heat the deformed area 3 on the back of the stainless steel car body panel 2 of the rail car along the direction of the weld seam 1 at a moving speed of 0.3m / min. At the same time, the protective gas Ar is blown into the heated area. The protective gas is blown in after the laser heating; the protective gas is composed of 5 parallel airflows arranged in a line along the moving direction of the laser heating; the blowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com