Preparation method of high-intensity composite material grid structure

A composite material and grid structure technology, applied in the field of composite material preparation and application, can solve problems such as slow progress, and achieve the effects of strong operability, strong designability, and reliable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

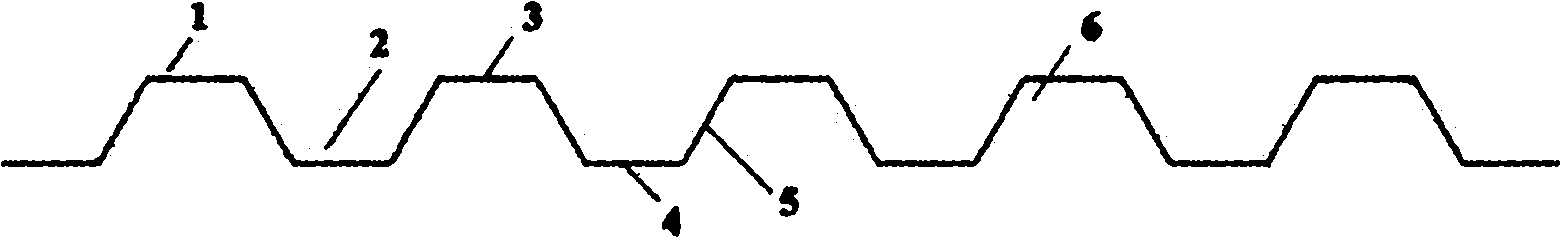

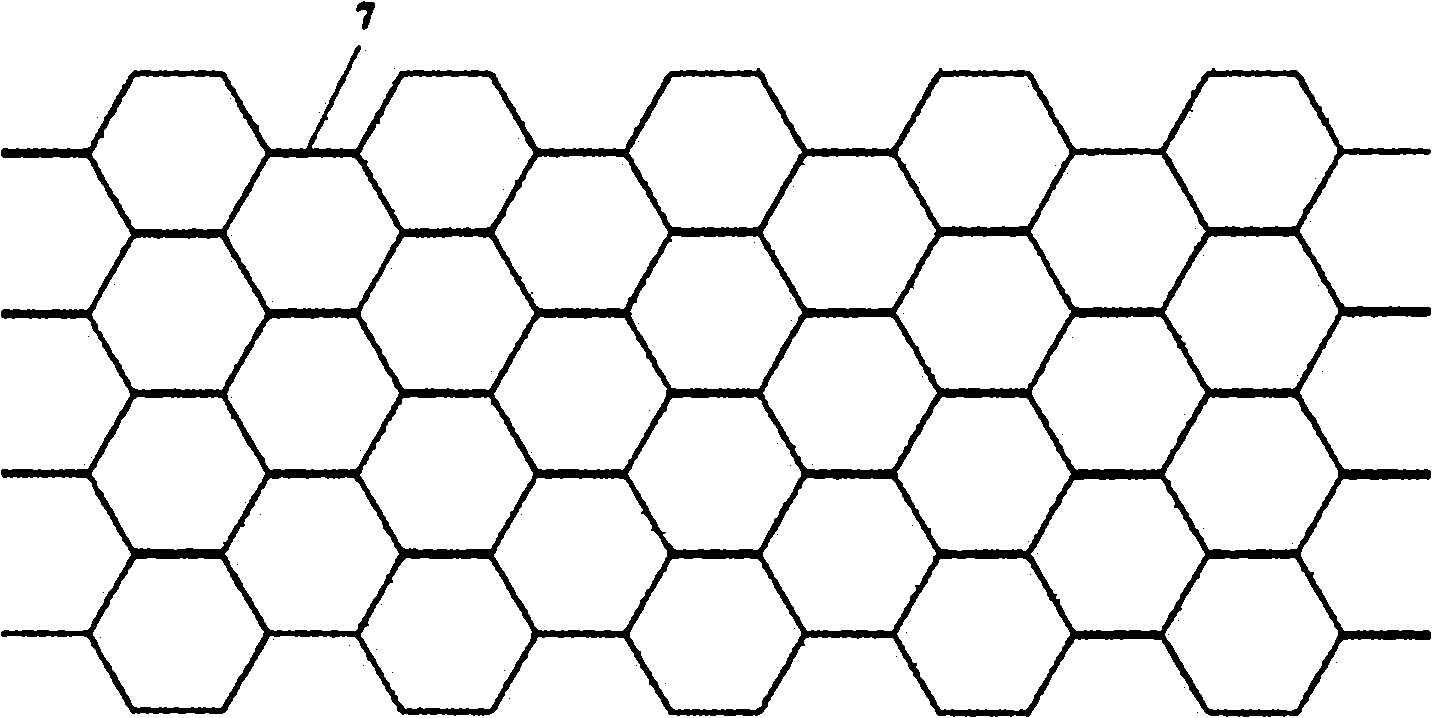

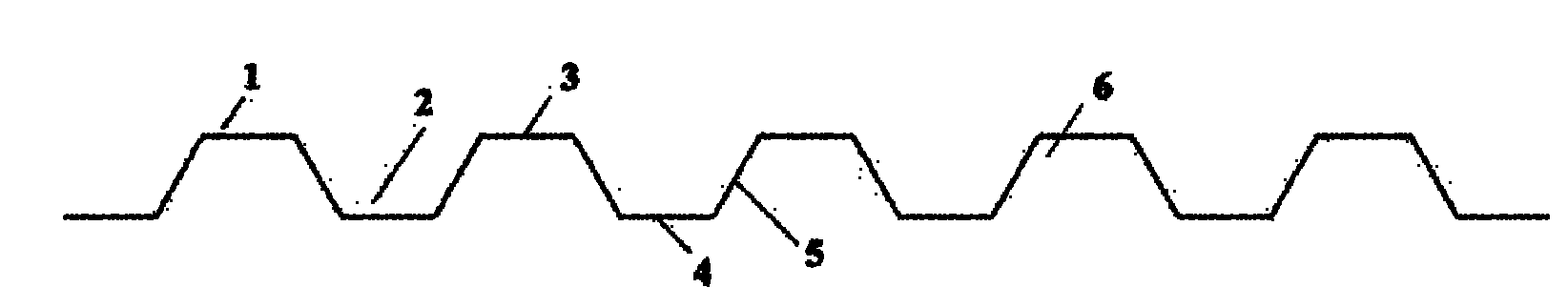

[0026] According to the 0.15mm thick unidirectional carbon fiber / epoxy resin prepreg, the first layer is 0 degrees / the second layer is 90 degrees / the third layer is 0 degrees / the fourth layer is 90 degrees / the fifth layer is 0 degrees (a total of 5 layers ) arranged in a carbon fiber / epoxy resin prepreg. Using the compression molding process (the cross-section waveform of the mold used is trapezoidal, the angle between the trapezoidal slope and the upper bottom is 120 degrees, the cross-sectional wavelength is 20mm, and the amplitude is 10mm), the composite material prepreg is cured and formed into carbon fiber / epoxy corrugated board. Cut the carbon fiber / epoxy corrugated sheet along the direction parallel to the corrugation extension of the section to make a carbon fiber / epoxy corrugated sheet with a width of 15mm (such as figure 1 shown). The upper and lower sides of the carbon fiber / epoxy corrugated sheet are coated with epoxy resin, and the lower surface of a corrugate...

Embodiment 2

[0028] 0.18mm thick unidirectional glass fiber / unsaturated polyester resin prepreg according to the first layer 0 degree / second layer 90 degree / third layer 0 degree / fourth layer 90 degree / fifth layer 0 degree / The sixth layer of 90 degrees / the seventh layer of 0 degrees (total 7 layers) is arranged to make glass fiber / unsaturated polyester resin prepreg. Using the pultrusion molding process (the cross-section of the die used in the pultrusion molding process is rectangular, that is, the angle between the hypotenuse and the upper bottom is 90 degrees, the wavelength of the cross-section is 25mm, and the amplitude is 10mm), the composite material prepreg is processed. Curing and molding to make glass fiber / unsaturated polyester corrugated board. Cut the glass fiber / unsaturated polyester corrugated sheet along the direction parallel to the extension of the section corrugation to make a glass fiber / unsaturated polyester corrugated sheet with a width of 10mm (such as figure 1 show...

Embodiment 3

[0030] According to the 0.15mm thick unidirectional carbon fiber / bismaleimide resin prepreg, the first layer is 0 degrees / the second layer is 90 degrees / the third layer is 0 degrees / the fourth layer is 0 degrees / the fifth layer is 0 degrees / The sixth layer is 90 degrees / the seventh layer is 0 degrees (a total of 7 layers) to make carbon fiber / bismaleimide resin prepreg. Using the pultrusion molding process (the section waveform of the die used in the pultrusion molding process is trapezoidal, the angle between the trapezoidal slope and the upper bottom is 120 degrees, the section wavelength is 20mm, and the amplitude is 12mm), the composite material is prepreg The cloth is cured and formed into a carbon fiber / bismaleimide corrugated board. Cut the carbon fiber / bismaleimide corrugated sheet along the direction parallel to the extension of the cross-sectional corrugation to make a carbon fiber / bismaleimide corrugated sheet with a width of 10mm (such asfigure 1 shown). The uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com