Combined-submerged pit water process and equipment

A submerged and cellar water technology, applied in the direction of osmosis/dialysis water/sewage treatment, etc., to achieve the effect of reducing equipment cost, simple and practical process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

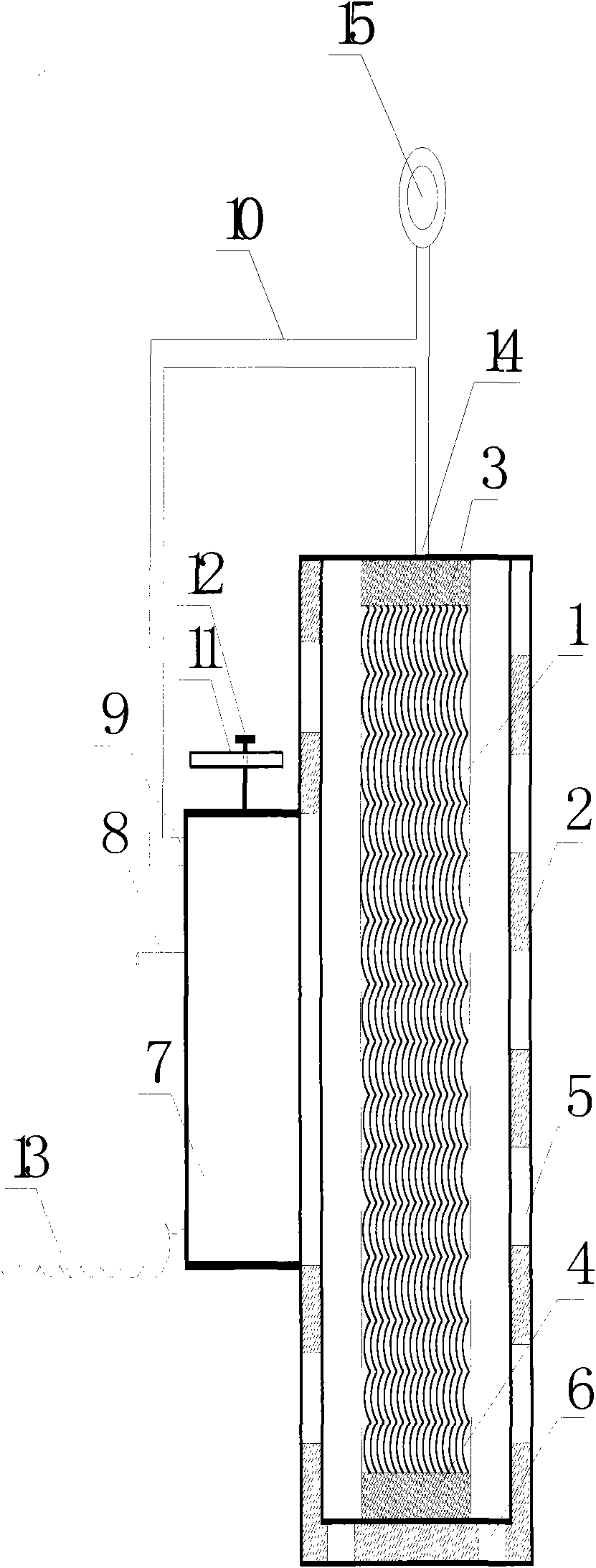

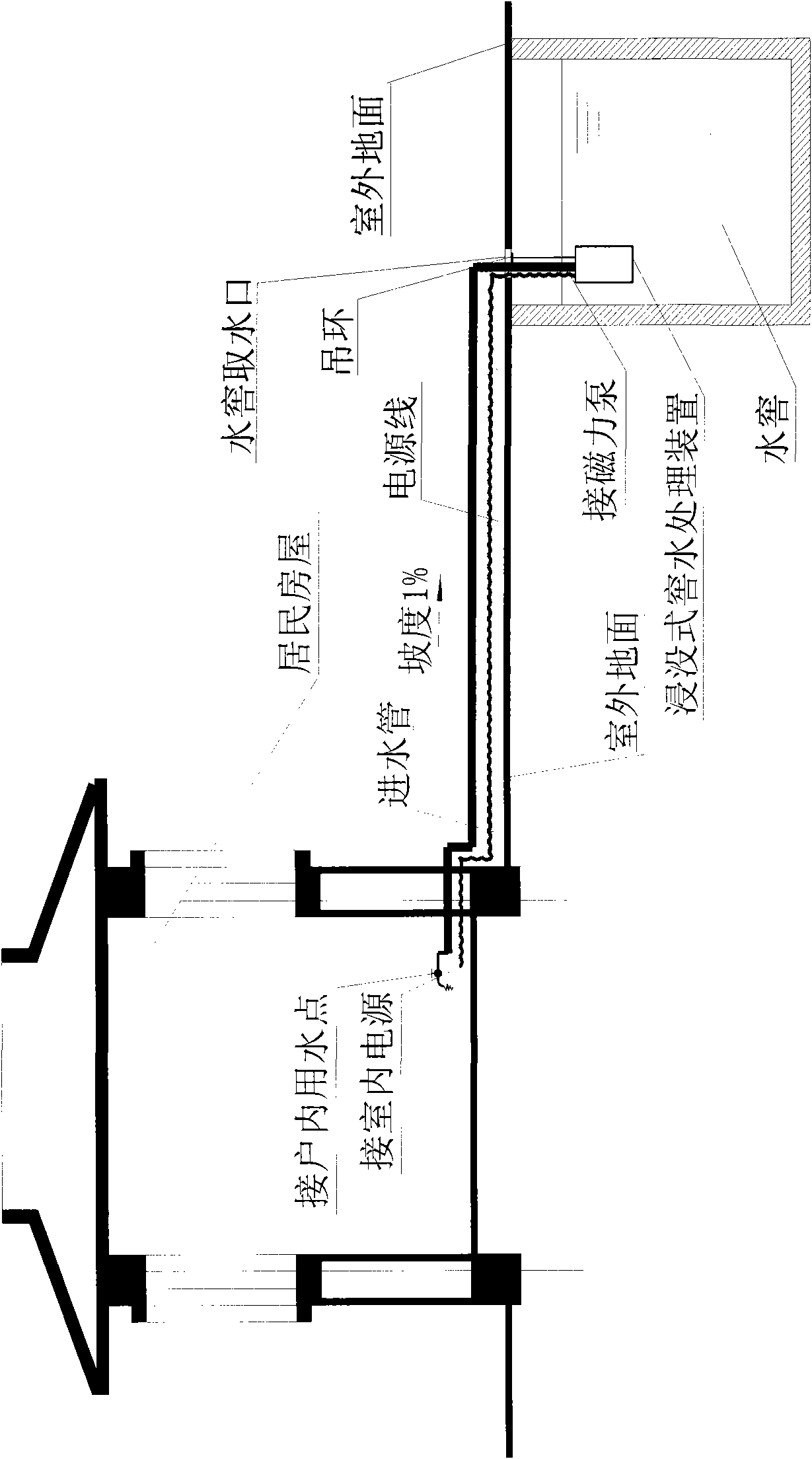

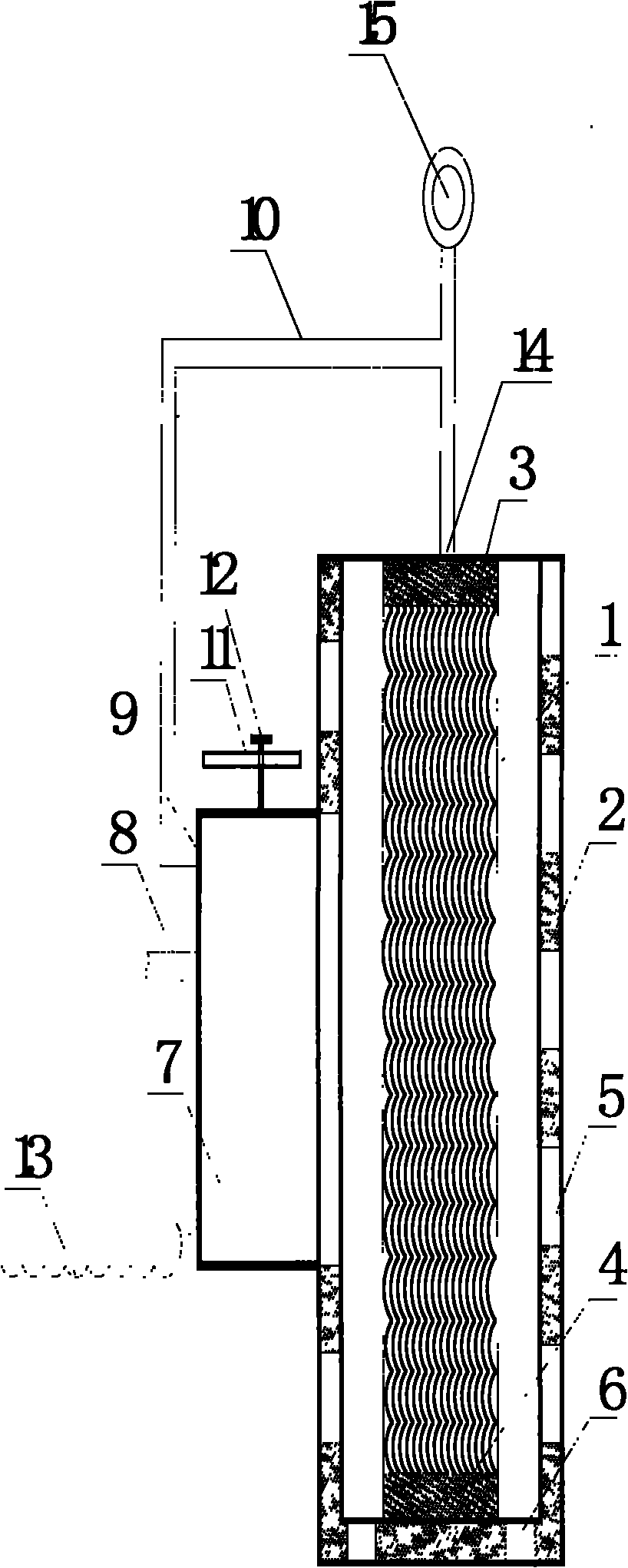

[0027] a. The cellar water treatment technology is transformed into treatment equipment according to the method. The film surface is 10m in total 2 The lower end of the high-throughput hollow fiber ultrafiltration membrane filament group is blocked with epoxy resin, and the upper end is fixed with epoxy resin, leaving each hollow fiber water outlet, which is collected in a unified water outlet pipe.

[0028] b. Put the sealed hollow fiber bundles in the injection-molded outer tube with openings on the outer wall. The cellar water can enter the ultrafiltration membrane through the wall holes. Under the vibration, it falls off the membrane and falls back into the cellar water through the sewage outlet.

[0029] c. The miniature submersible electromagnetic pump is fixed on the outer wall of the injection molding casing, and the suction force of the suction port is used to suck the cellar water through the ultrafiltration membrane into the suction port of the pump, and after pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com