Method for preparing rare earth doped optic fiber preform

A technology of optical fiber preform and rare earth doping, which is applied in the field of optical fiber manufacturing to achieve the effect of performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

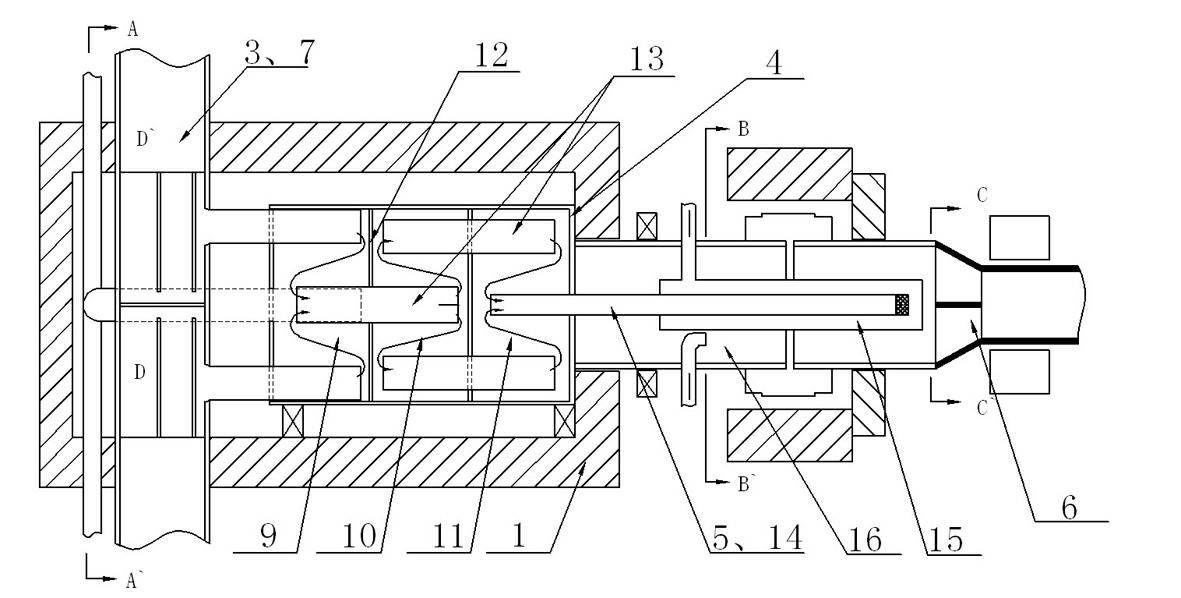

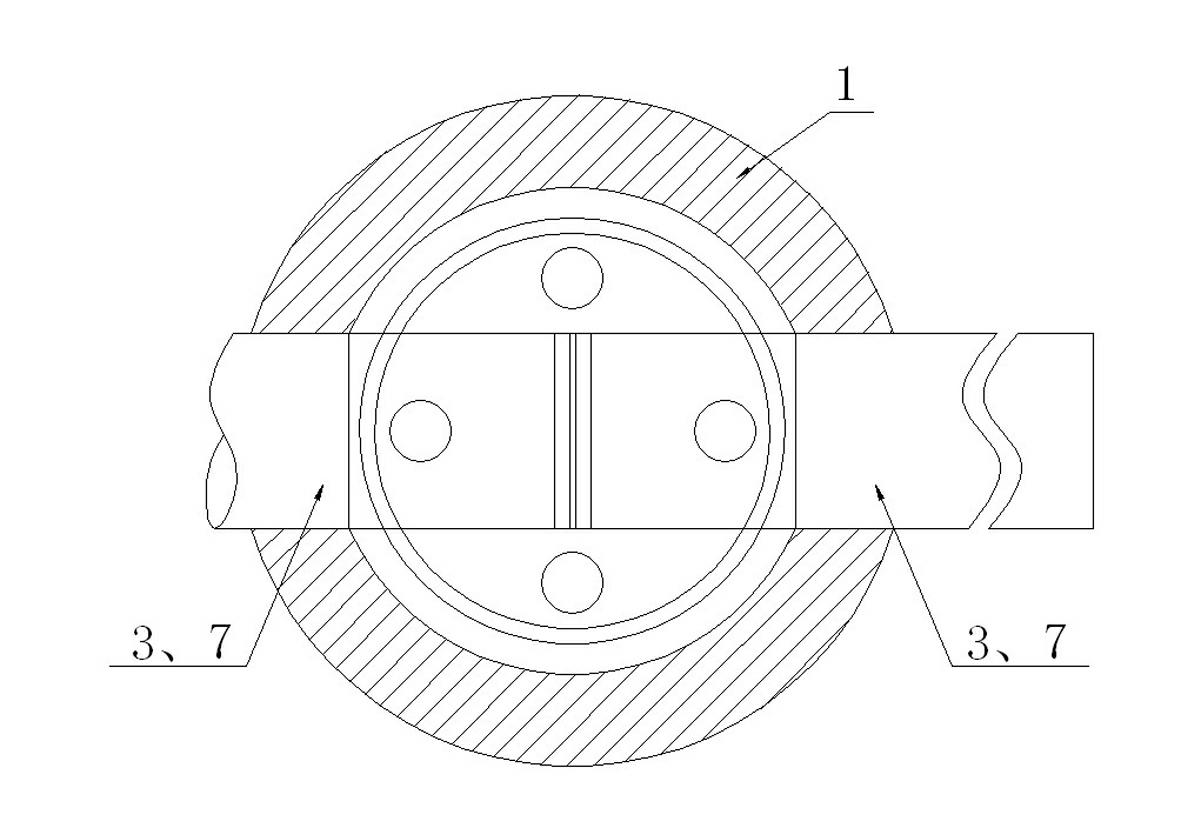

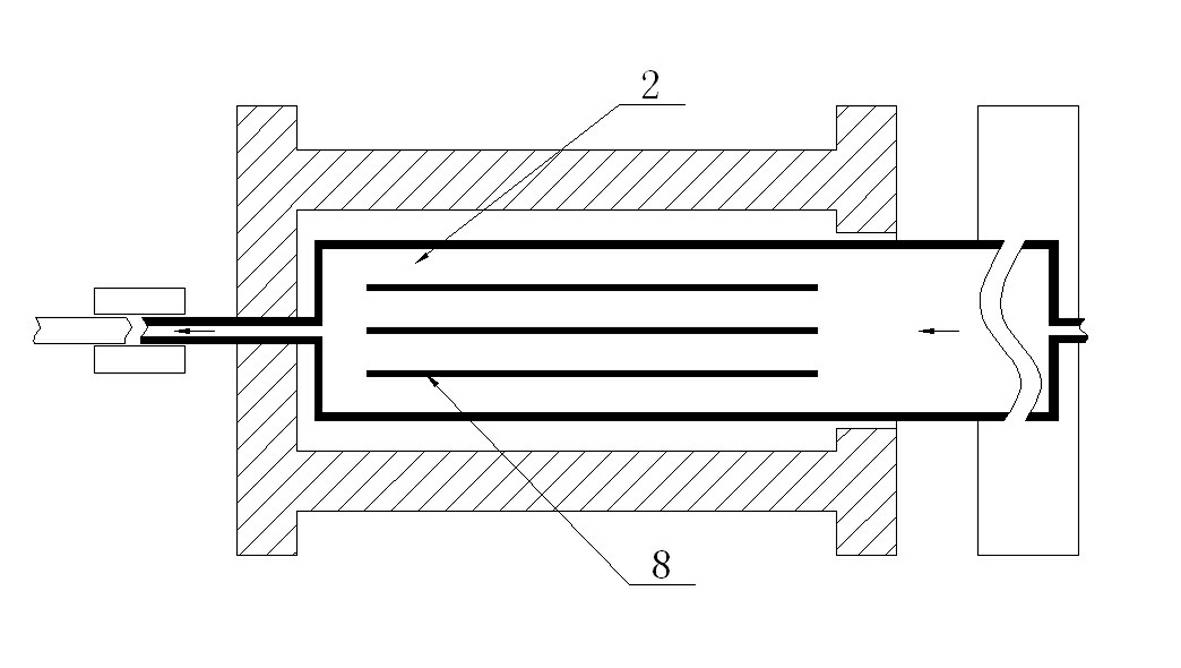

[0028] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

[0029] Such as Figure 1-7 As shown, the labels 1-17 respectively represent: graphite resistance heating furnace 1, AlCl 3 Gasifier 2, rare earth chloride gasifier 3, carrier gas mixing channel 4, transport gas channel 5, reaction tube 6, quartz loading chamber 7, quartz partition 8, first mixing chamber 9, second mixing chamber 10 , The third mixing chamber 11, partition 12, pipeline 13, metal mixed gas heating furnace 14, protective gas tube 15, glass component gas tube 16, quartz stirring plate 17.

[0030] see figure 1 , the device structure involved in this method mainly includes graphite resistance heating furnace 1, AlCl 3 Gasification furnace 2, transport gas channel 5, reaction tube 6 and gas control cabinet (not shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com