Control oil way of variable valve timing device

A valve timing and oil circuit control technology, which is applied to valve devices, non-mechanically actuated valves, mechanical equipment, etc. Cost increase and other issues, to achieve the effect of shortening the longitudinal layout size, simplifying the structure design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

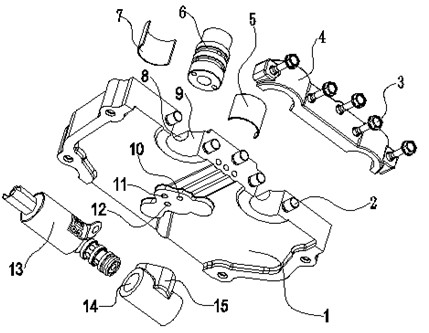

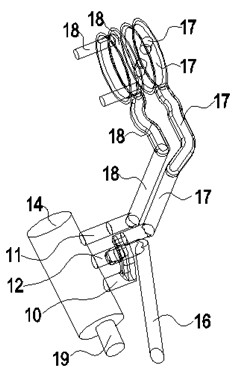

[0022] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

[0023] Such as figure 1 , 4 As shown, the control oil circuit of the variable valve timing device of the present invention includes the main oil passage 16, the advance angle oil passage 17, and the retard angle oil passage 18 arranged inside the front end of the cylinder head 1, wherein the main oil passage 16 starts from the bottom of the cylinder head 1 Leading in, the advancing angle oil passage 17 and the retarding angle oil passage 18 are led out from the top of the cylinder head 1 .

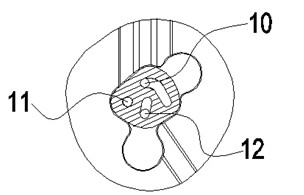

[0024] Such as figure 1 , 2 , 3, an oil control valve installation hole 14, an oil inlet hole 12, an oil inlet hole 10, a late angle oil hole 11, and an oil return passage 19 are arranged inside the upper end of the front cover housing 15, wherein the oil inlet hole 12 and the The main oil passage 16 on the cylinder head 1 communicates, the oil inlet hole 10 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com