Combination system of stirling engine and combustion gas turbine utilizing liquefied natural gas

A Stirling engine and liquefied natural gas technology, which is applied to gas turbine devices, hot gas variable displacement engine devices, engine components, etc., can solve the problems of not considering how to use the cooling capacity of natural gas, and not proposing an ethylene glycol solution cooling system. , to achieve the effect of increasing output, high efficiency and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention will not be limited thereby.

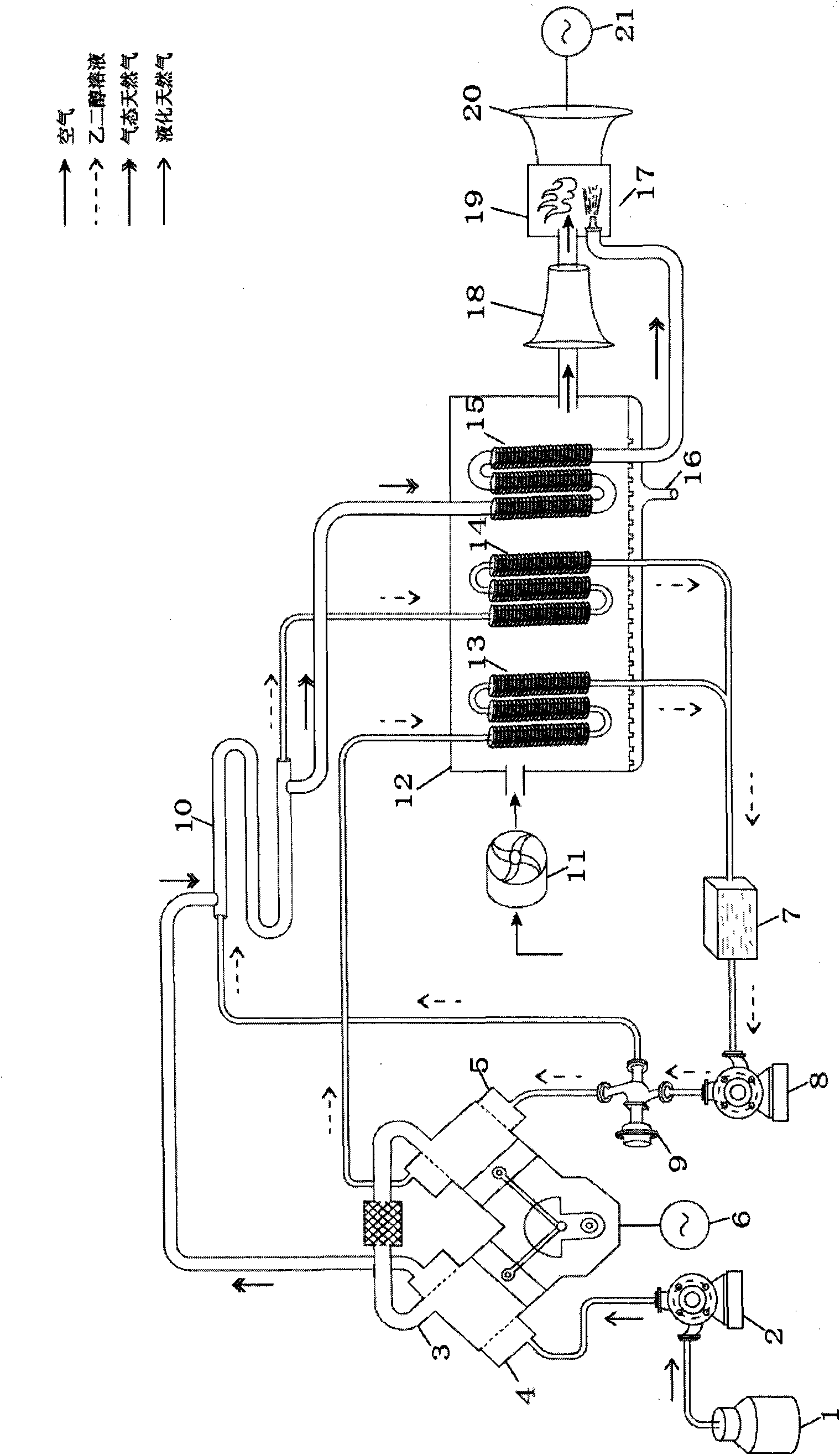

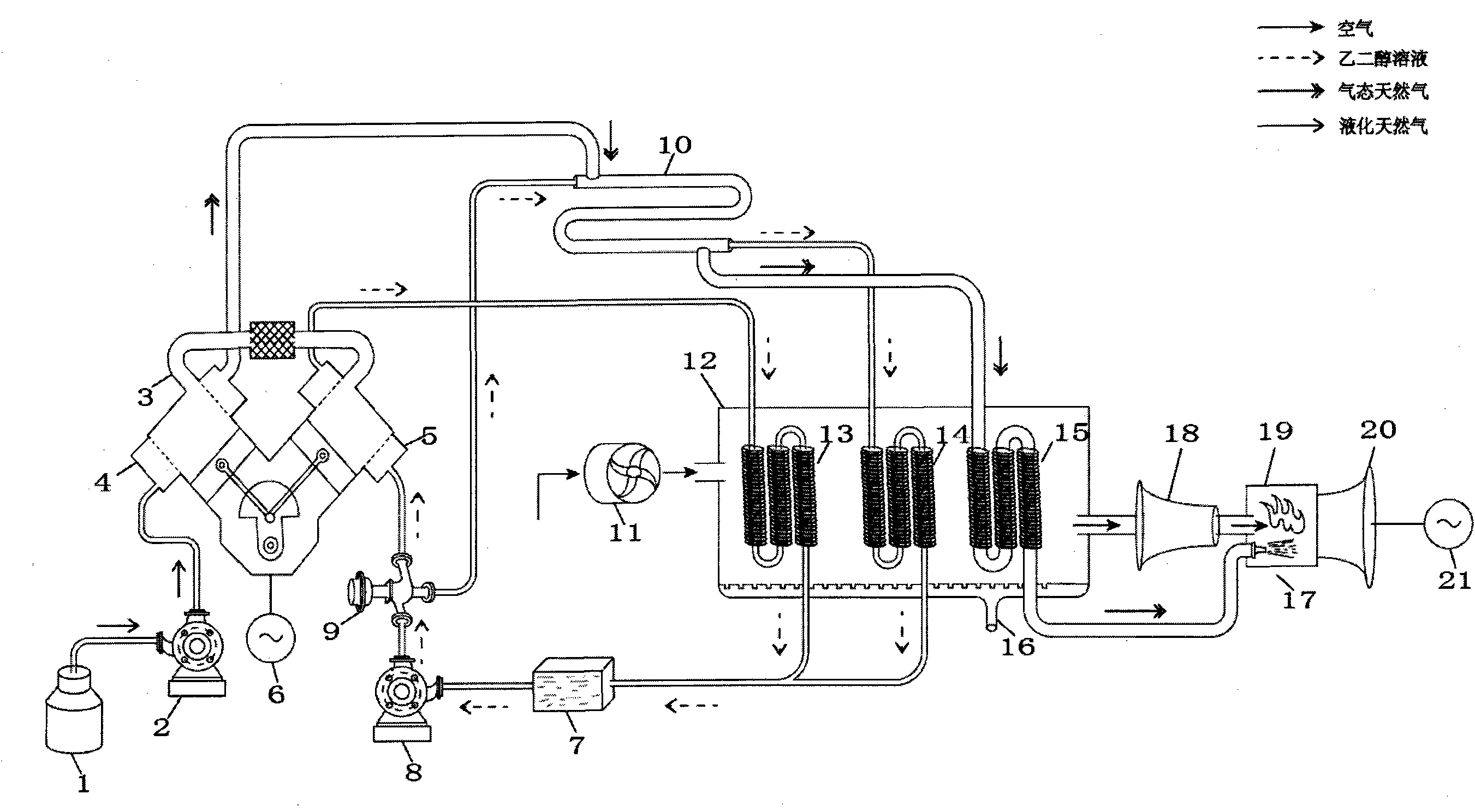

[0028] Please see first figure 1 , figure 1 It is a structural schematic diagram of the combination system of Stirling engine and gas turbine utilizing liquefied natural gas according to the present invention. As shown in the figure, a Stirling engine and gas turbine combined system using liquefied natural gas is characterized in that the combined system includes:

[0029] The liquefied natural gas system includes a liquefied natural gas liquid storage tank 1 and a liquefied natural gas pump 2;

[0030] Stirling engine 3 has cold end heat exchanger 4, hot end heat exchanger 5 and learning equipment 6;

[0031] Glycol solution system comprises ethylene glycol solution storage tank 7 and ethylene glycol solution pump 8;

[0032] Three-way regulating valve 9, casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com