Method for detecting state of high-speed high-vacuum turbomolecular pump

A turbomolecular pump and high vacuum technology, applied in pumps, pump control, axial flow pumps, etc., can solve problems such as slow speed, difficult operation, high price, etc., to reduce unexpected downtime rate, avoid expansion of failure, The effect of reducing the measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

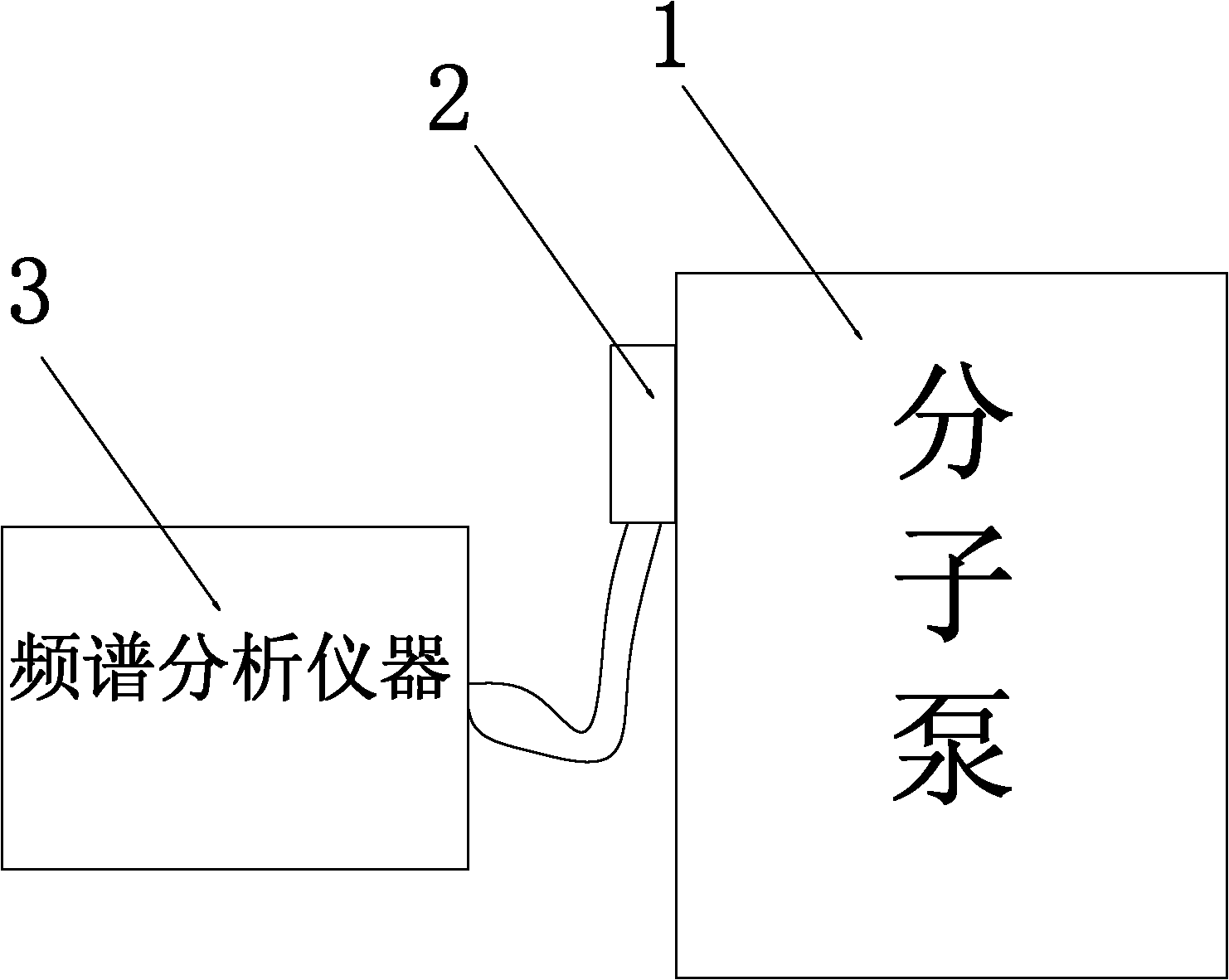

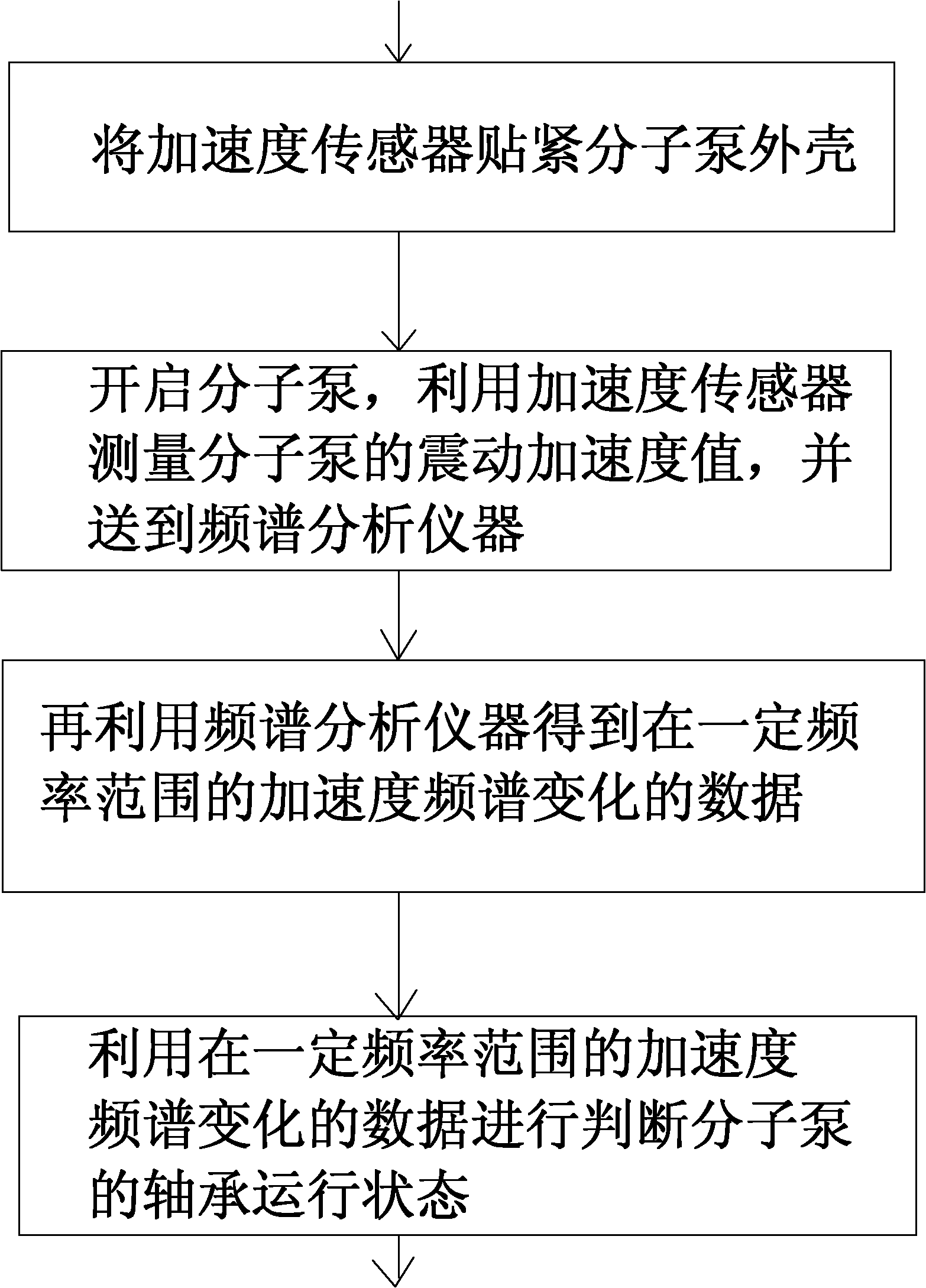

[0028] Such as figure 1 , figure 2 As shown, the present invention detects the method for high-speed high-vacuum turbomolecular pump state, and it comprises the steps:

[0029] A) paste the acceleration sensor 2 on the shell of the molecular pump 1;

[0030] B) Turn on the molecular pump 1, and use the acceleration sensor 2 to measure the vibration acceleration value of the molecular pump 1 and send it to the spectrum analyzer 3;

[0031] C) re-utilize the spectrum analysis instrument 3 to obtain the data of the frequency spectrum change of the acceleration value in a certain frequency range;

[0032] D) Judging the bearing operation state of the molecular pump 1 by using the data of the frequency spectrum change of the acceleration value in a certain frequency range: (D1) When it is in a high-frequency state, the acceleration signal value is small and there is no noise, indicating that the molecular pump is in a good operating state; (D2) When it is in the high frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com