Vacuum degree regulating system for steam injection pump

A technology of vacuum degree and jet pump, applied in the direction of jet pump, pump, non-displacement pump, etc., can solve the problems of vacuum pump being unable to accurately stabilize vacuum degree, prolonged vacuum refining time, unfavorable process flow, etc., and achieve good economic benefits, treatment The effect of shortened time and smooth process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

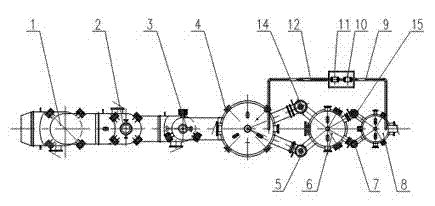

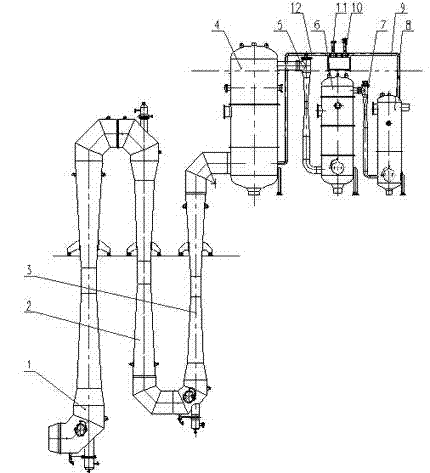

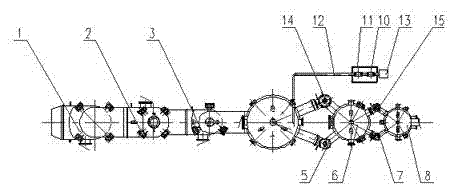

[0015] Such as figure 1 , figure 2 Shown, a kind of vacuum adjustment system for water vapor jet pump comprises: the first booster pump 1, the second booster pump 2, the third booster pump 3, the first condenser 4, the first jet pump 5. The second jet pump 7, the first auxiliary jet pump 14, the second auxiliary jet pump 15, the first condenser 4, the second condenser 6, the third condenser 8, the first booster pump 1, the second booster pump The pressure pump 2 and the third booster pump 3 are connected in sequence, and finally connected to one end of the first condenser 4, and the first condenser 4 is connected to the second condenser 6 through the first jet pump 5 and the first auxiliary jet pump 14 respectively. , the second condenser 6 is connected to the third condenser 8 through the second jet pump 7 and the second auxiliary jet pump 15 respectively, and the first condenser 4 and the third condenser 8 are connected through the exhaust pipe 12, the pneumatic regulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com