LNG (liquefied natural gas) pump-free air-entrapping method with BOG (boil off gas) recycling function and LNG pump-free air-entrapping device

A technology of function and equipment, which is applied in the field of liquid natural gas refilling, can solve the problems of increasing operating costs and achieve the effects of reducing operation and maintenance costs, saving power consumption, and reducing investment and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

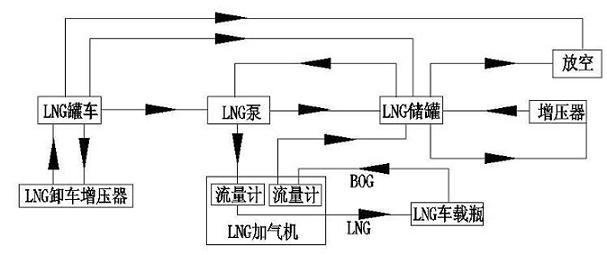

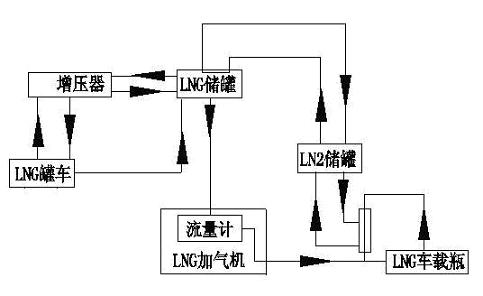

Method used

Image

Examples

Embodiment 1

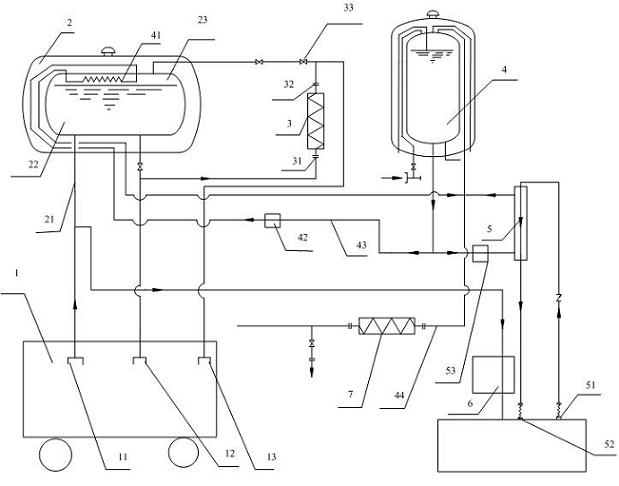

[0042] Such as image 3 As shown, the LNG pumpless refueling equipment with BOG recovery function includes the following components: LNG refueling machine 6, tank truck 1, LNG storage tank 2, supercharger 3, liquid nitrogen cold trap 5, and liquid nitrogen storage tank 4 .

[0043] The tank car 1 is provided with a tank car liquid discharge port 11 , a tank car pressurized liquid outlet 12 and a tank car pressurized air return port 13 .

[0044] The LNG storage tank 2 is provided with a storage tank inlet and outlet pipe 21 connected to the liquid discharge port of the tank truck and the liquid inlet of the LNG dispenser at the same time, and is used to convert the BOG of the LNG storage tank into LNG and input it into the LNG storage tank liquid. The liquid nitrogen condensation device 41 in the phase space.

[0045] The supercharger 3 is provided with a liquid inlet 31, an air return port 32, and a tank car or LNG storage tank pressurization selection valve 33; the liquid ...

Embodiment 2

[0060] The LNG pumpless filling method with BOG recovery function includes the following steps:

[0061] (A) Pumpless unloading and tanker BOG recovery: connect the tanker loaded with LNG to the LNG storage tank through the infusion hose or the unloading arm; open the liquid nitrogen condensation device in the LNG storage tank to condense the BOG in the LNG storage tank At this time, the pressure in the LNG storage tank is reduced; at the same time, the LNG in the tank car is pressurized so that the pressure of the LNG in the tank car is higher than that of the LNG storage tank, relying on the LNG tank car and the LNG storage tank. Pressure difference and complete the unloading of LNG through the infusion hose or the unloading arm;

[0062] (B) Pumpless refueling and recovery of vehicle-mounted steel cylinder BOG: Connect the vehicle-mounted LNG cylinder to the LNG dispenser and the vehicle-mounted BOG interface of the liquid nitrogen cold trap; open the liquid nitrogen cold t...

Embodiment 3

[0066] Example 3 Liquid nitrogen (LN 2 ) consumption calculation

[0067] The normal air supply pressure of LNG fuel vehicle engine is generally required to be between 0.8-1.2MPa (usually 0.8-1.0MPa, Max1.6MPa). In order for the LNG fueled vehicle to operate normally, the LNG saturation pressure that is required to be filled into the vehicle-mounted LNG cylinder should generally not be lower than 0.8MPa, although the booster of the LNG vehicle-mounted cylinder can be used for boosting when the saturation pressure is lower than this, so as to Make the pressure of the LNG steel cylinder reach the saturation state of no less than 0.8MPa, but it will take a certain time to pressurize and make the pressure of the entire LNG cylinder reach the saturation pressure of no less than 0.8MPa, which may affect the normal operation of the car. Therefore, as the LNG storage tank of the supporting LNG filling station, it is best to control the normal operating pressure at no less than 0.8MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com