Display apparatus and manufacturing method thereof

一种显示装置、显示介质层的技术,应用在辨认装置、冷阴极制造、电极系统制造等方向,能够解决高分子材料层翘曲、多一、应力残留等问题,达到简化封装步骤的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order for those skilled in the art to have a better understanding of the present invention, preferred embodiments of the present invention are listed below, together with the accompanying drawings, to describe in detail the composition and desired effects of the present invention.

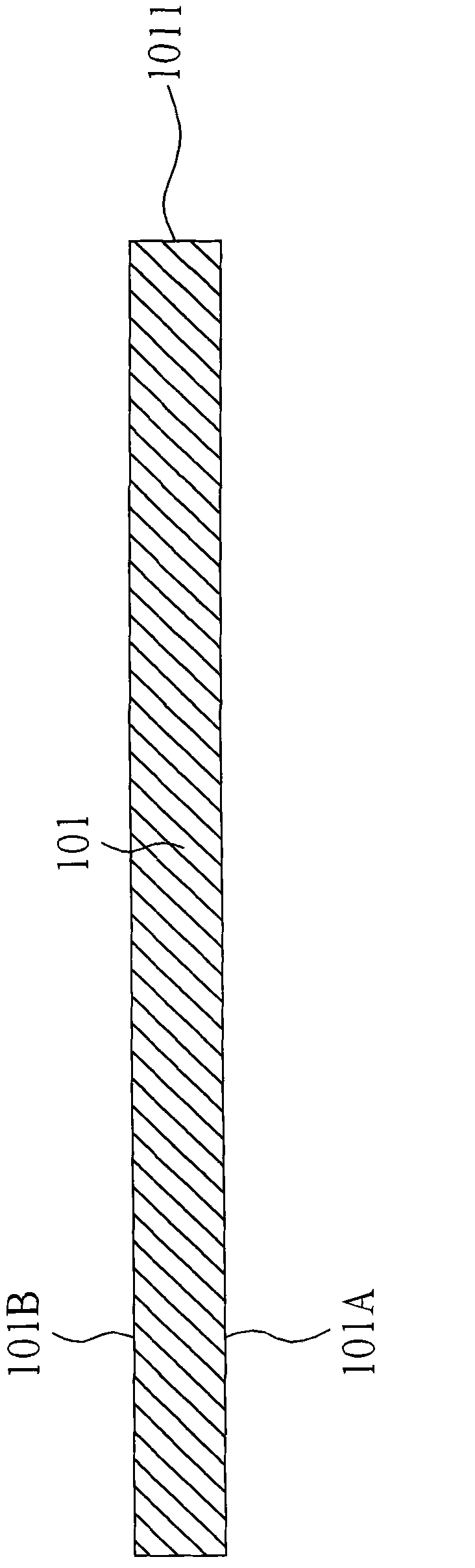

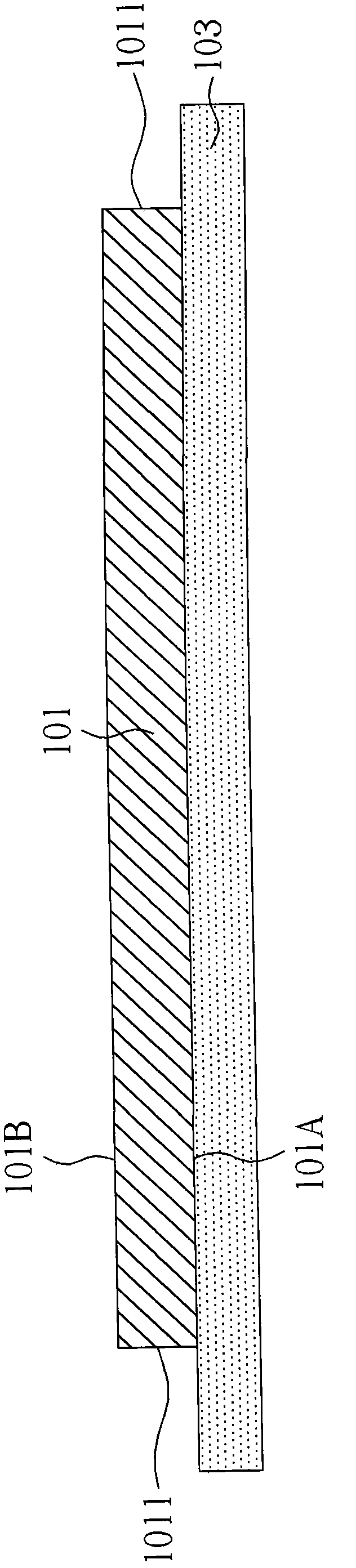

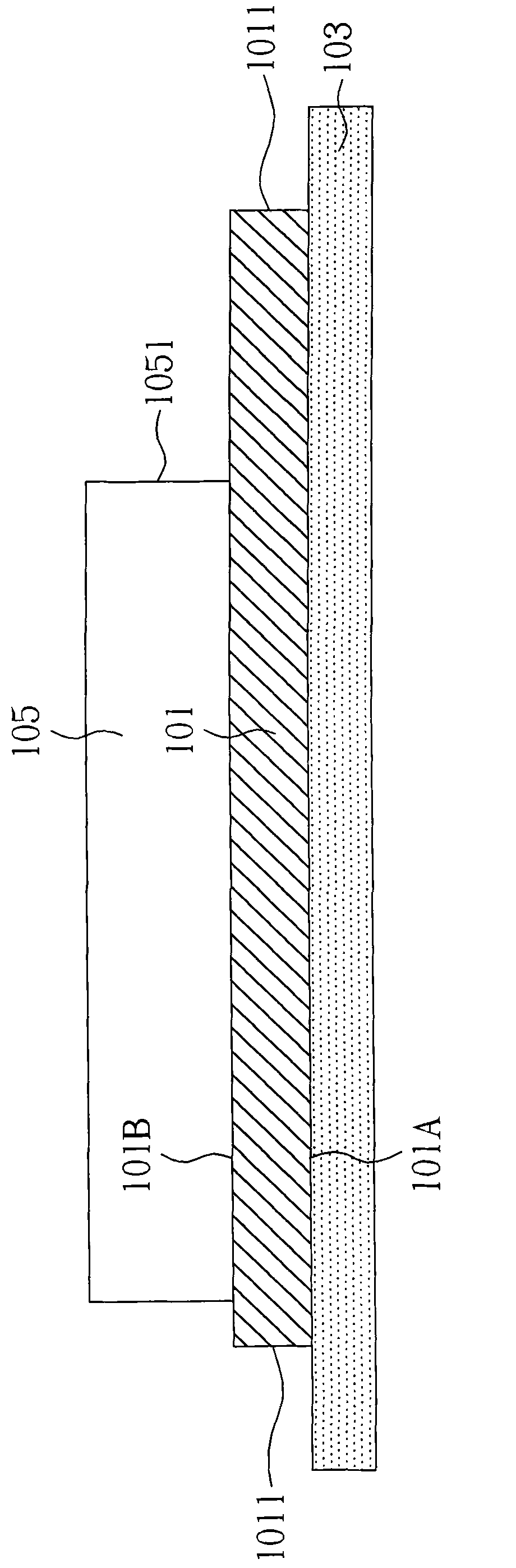

[0050] Please refer to Figure 1A-1F . Figure 1A-1F A schematic cross-sectional view of manufacturing a display device according to a first embodiment of the present invention is shown. Such as Figure 1A As shown, firstly, a substrate 101 is provided, and the substrate 101 is a flexible soft substrate such as a plastic substrate or a hard substrate such as a glass substrate or a quartz substrate. The substrate 101 includes a first surface (rear surface) 101A, a second surface (front surface) 101B and a side surface 1011, and the second surface 101B of the substrate 101 is used for disposing an active device array (not shown). In this embodiment, the active element array is, for examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com