Novel direct-current converter valve thyristor damping loop

A technology of DC converter valves and thyristors, applied in the direction of output power conversion devices, electrical components, etc., can solve problems such as the gate plate voltage cannot be satisfied, there is no fast energy-taking circuit, and the probability of problems increases, so as to achieve the design idea Clear, functional, improved damping loop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

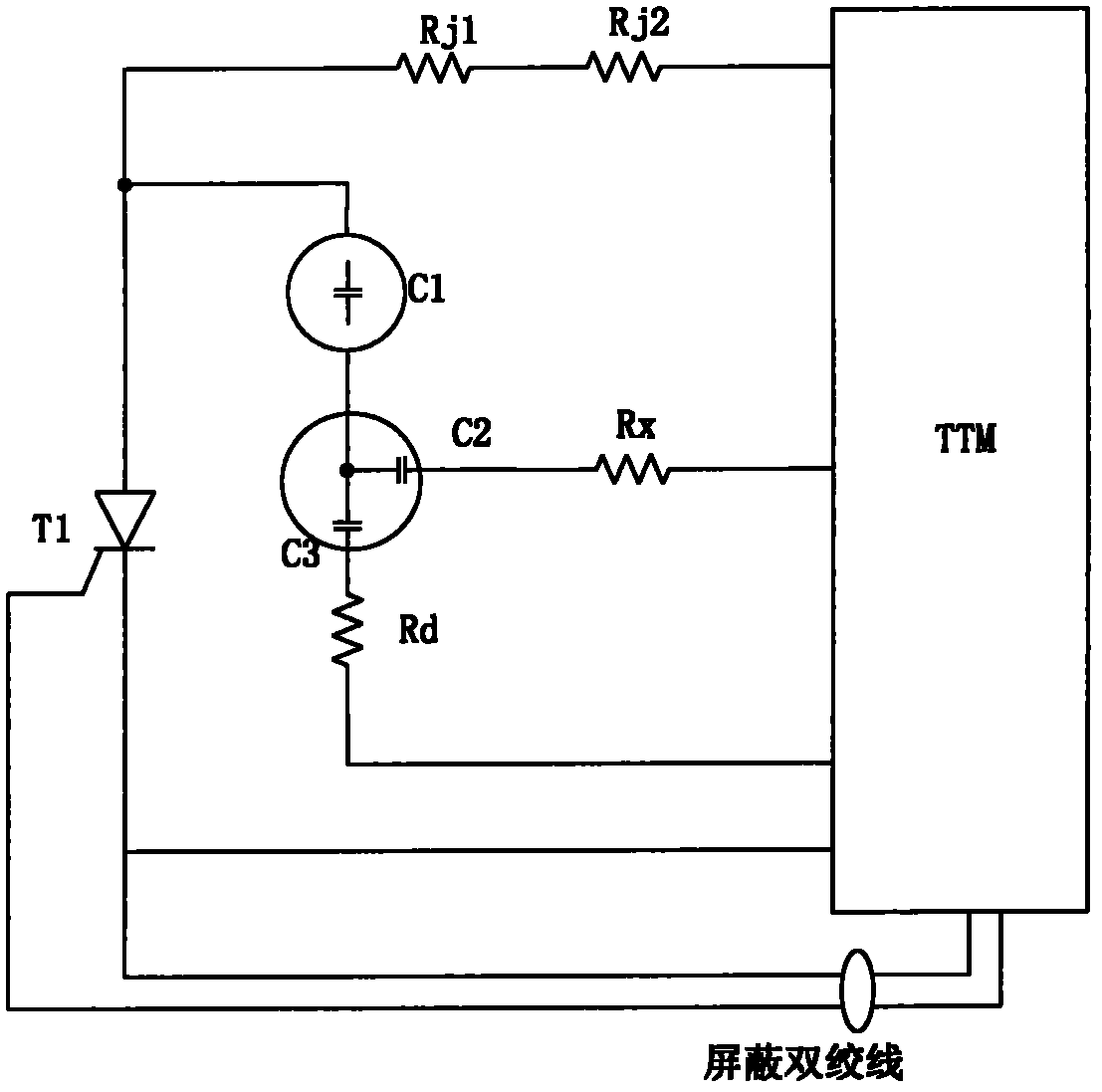

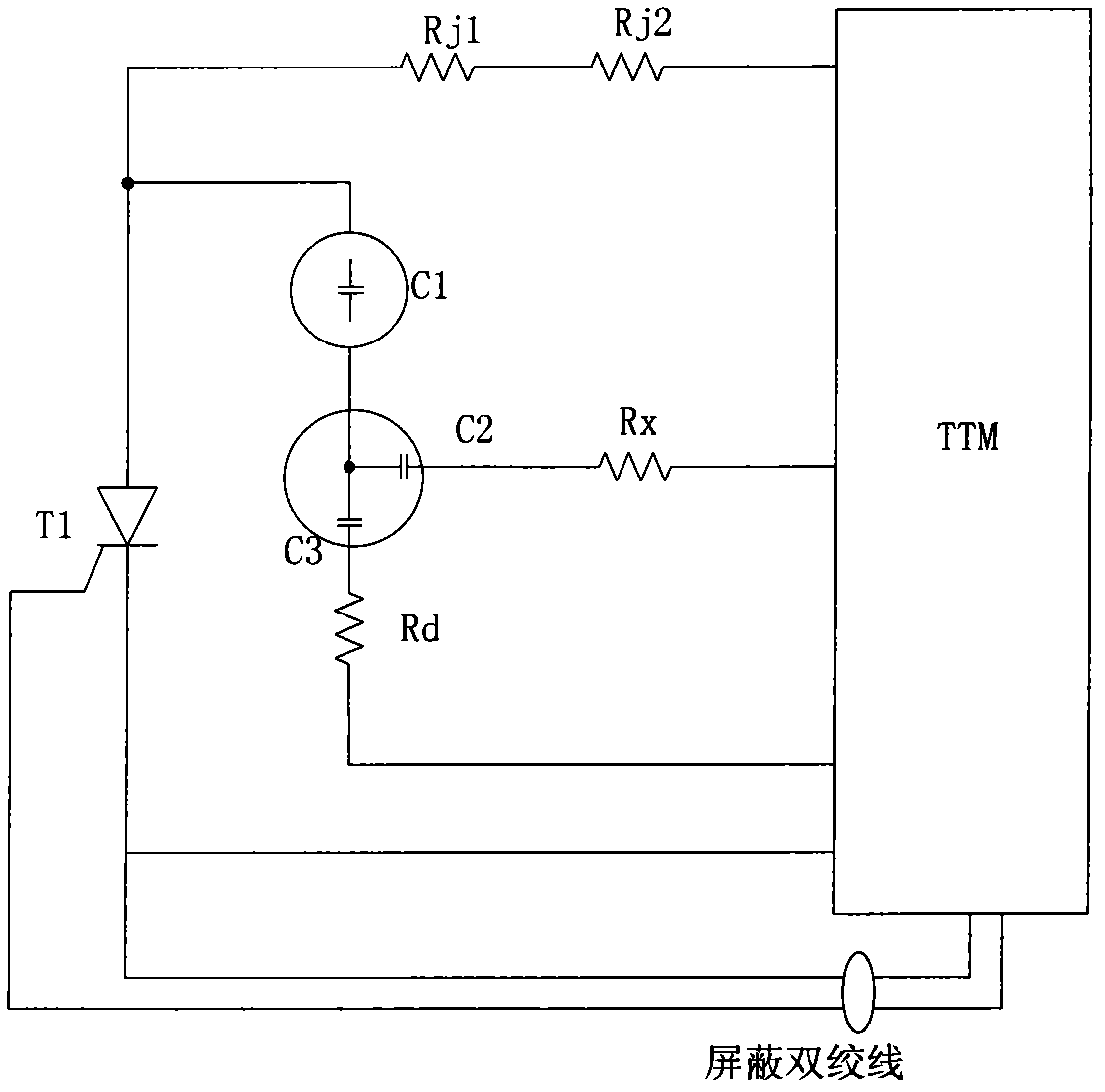

[0012] The electrical structure of the thyristor-level damping circuit of the converter valve designed in the present invention is as attached figure 1 shown.

[0013] attached figure 1 Among them, T1 is a thyristor, the anode of the thyristor is connected to the damping capacitor C1 and TTM, the cathode and gate of the thyristor are connected to the thyristor triggering and monitoring unit TTM, the anode and cathode of the thyristor are connected to the TTM, and the TTM is introduced in the circuit design The voltage of the thyristor is divided to convert the high voltage of the anode and cathode of the thyristor into a voltage range that can make the circuit board work normally.

[0014] The damping circuit of the DC converter valve is composed of DC voltage equalizing resistors Rj1, Rj2, damping capacitors C1, C2, C3, damping resistor Rd, and fast energy-taking resistor Rx. connect. Capacitors C2 and C3 are connected in parallel, and after being connected in parallel, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com