Cleaning device and coating device for slit nozzle

A technology of slit nozzle and cleaning device, which is applied in the direction of spraying device, spraying device, cleaning method and utensils, etc., which can solve the problems of resist film thickness variation, obstruction and disturbance of resist spray flow, etc., and improve the quality , Improve cleaning efficiency and improve cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the best mode for carrying out the present invention will be described with reference to the accompanying drawings.

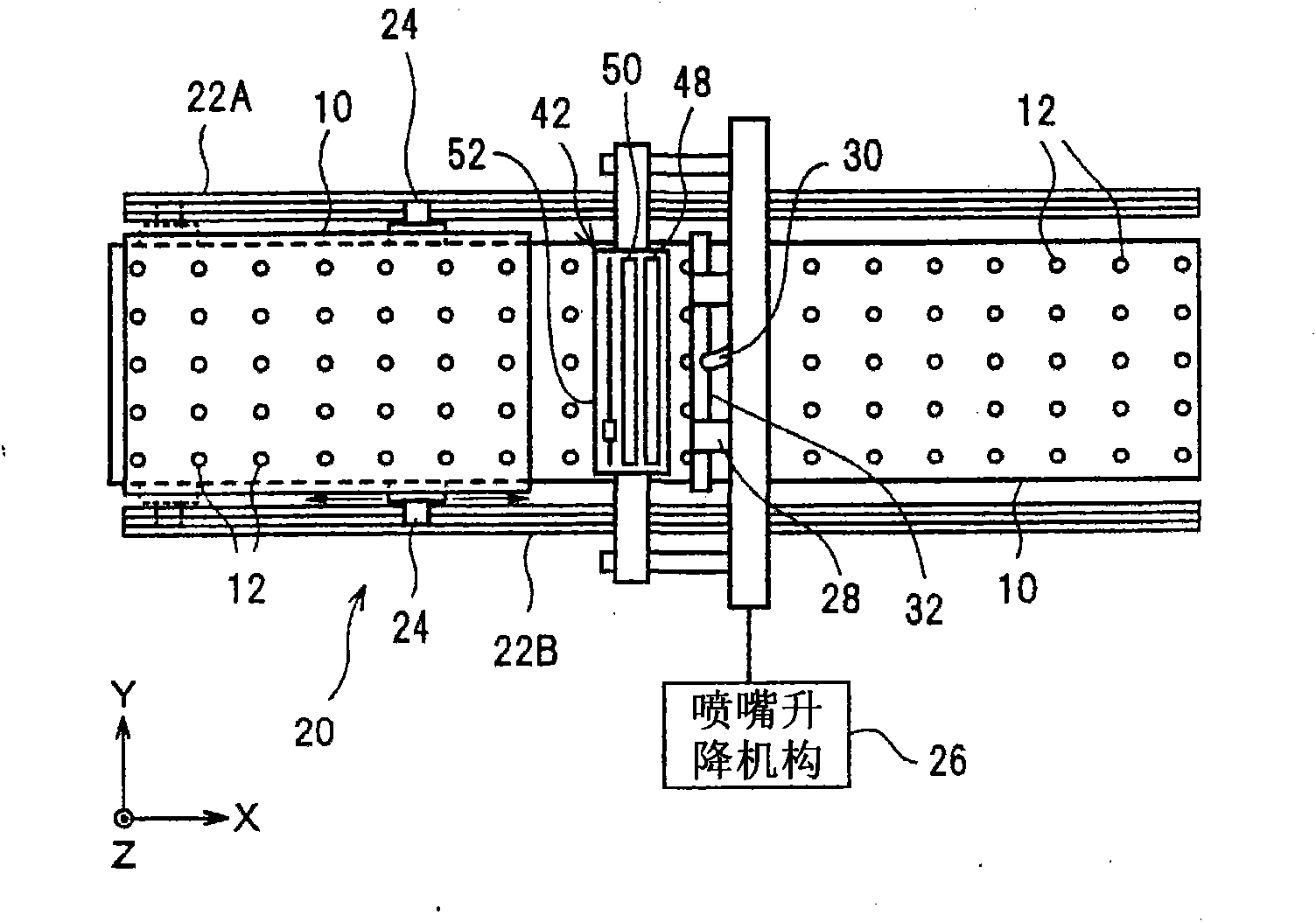

[0042] figure 1 This is a configuration example of a resist coating apparatus to which the slit nozzle cleaning apparatus of the present invention can be applied.

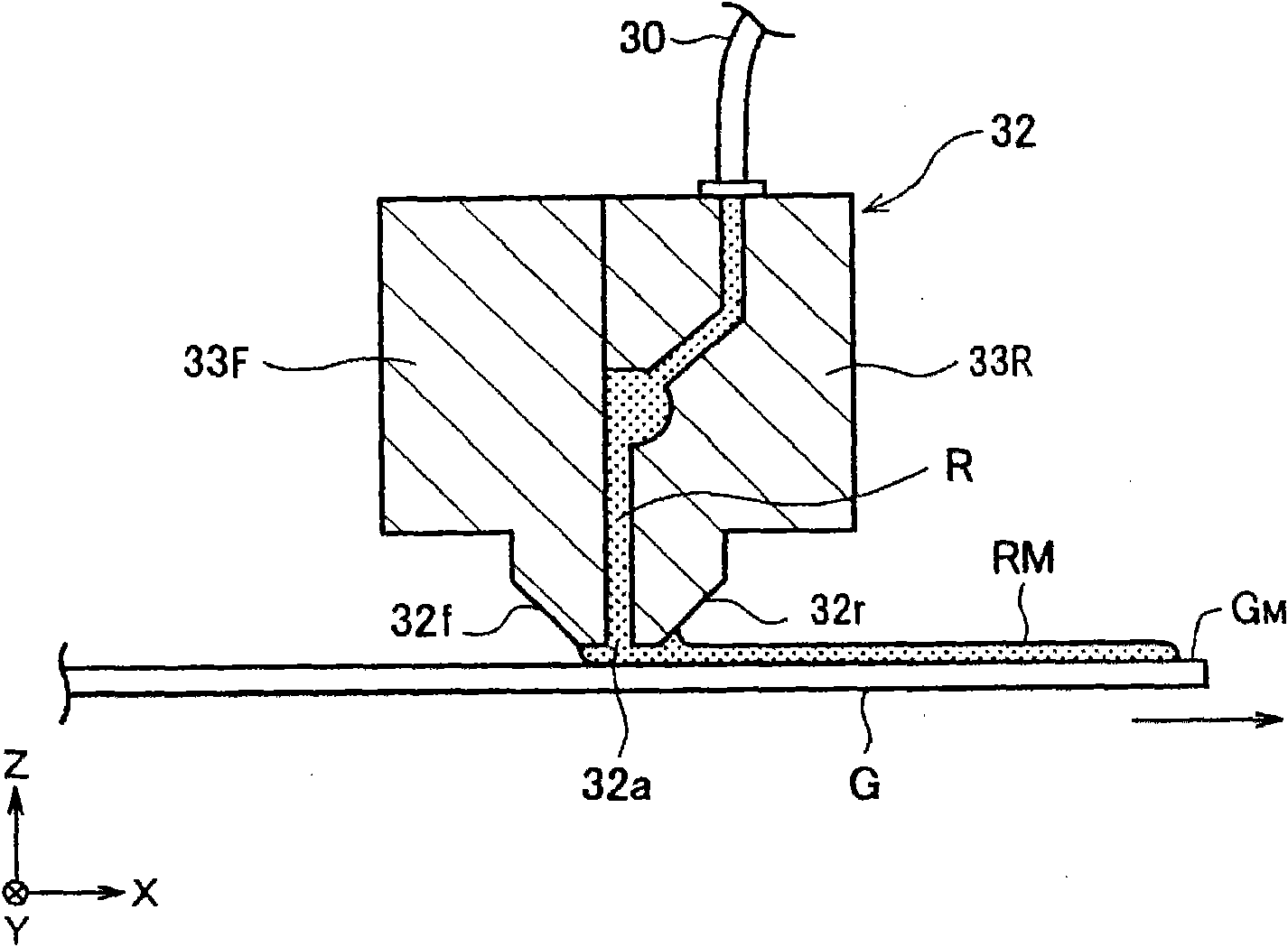

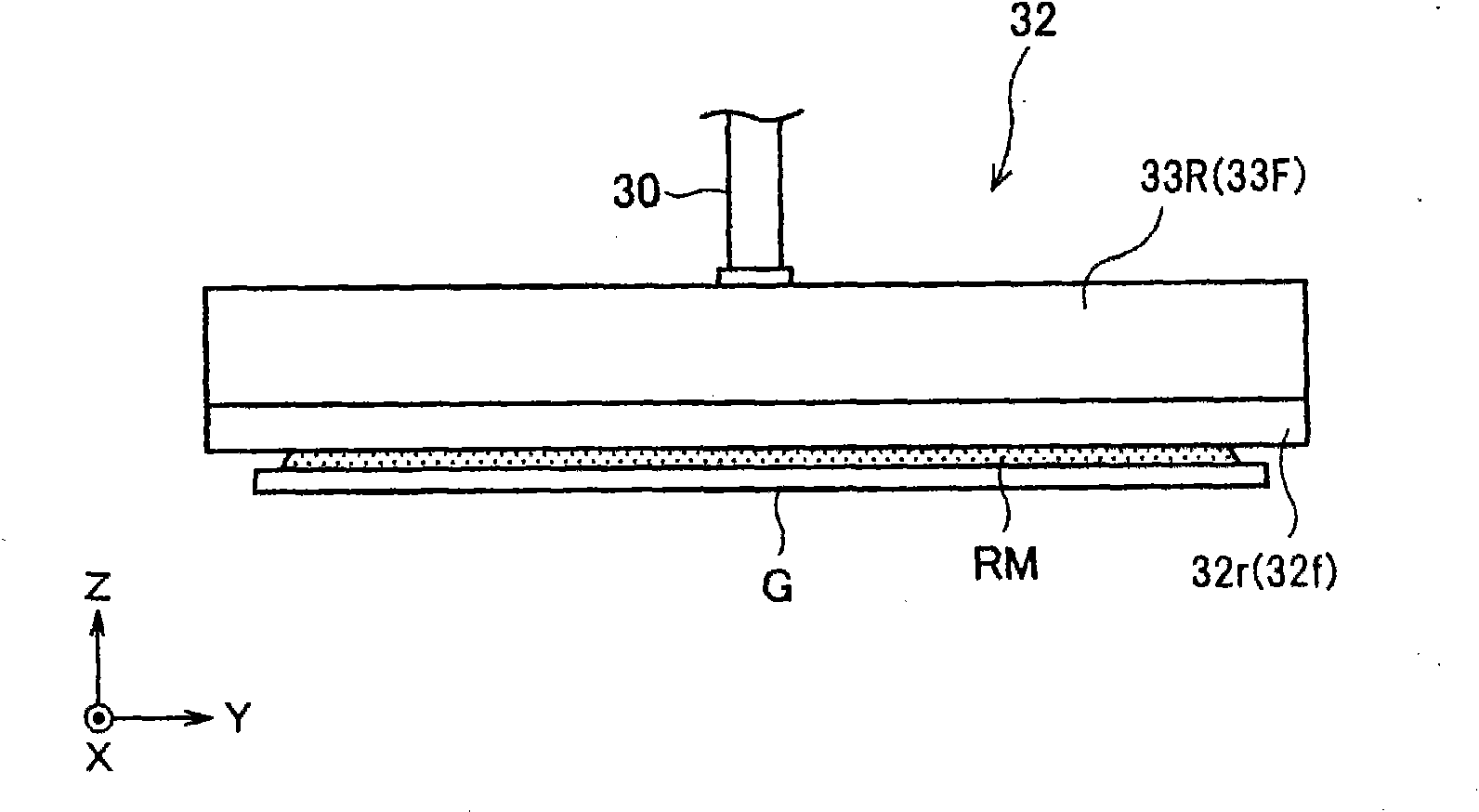

[0043] The resist coating device includes: a suspension table 10 for suspending a substrate to be processed, such as a glass substrate G for FPD, in the air by gas pressure; direction) the substrate transport mechanism 20 for transporting the substrate G suspended in the air; the slit nozzle 32 for supplying the resist liquid to the upper surface of the substrate G transported on the floating table 10; and the slit nozzle 32 for intermittent recovery of the coating process The nozzle recovery portion 42 of the slit nozzle 32 is provided.

[0044] The upper surface of the suspension table 10 is provided with a plurality of gas injection holes 12 for injecting a predetermined gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com