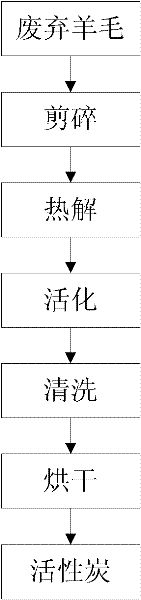

Method for preparing activated carbon by using waste wool

A technology for preparing activated carbon and wool, applied in the fields of material chemical industry and environmental science, can solve the problems of low added value, low utilization rate, secondary pollution, etc., and achieve high added value of products, large market value and social benefits, and avoid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Wash the wool with water several times to remove the impurities attached to the wool, and cut it into short hairs with a length of less than 5 mm; and place the dried wool raw material in a tubular reactor, under nitrogen protection at 10 ° C · min -1 The speed was heated to the set temperature of 260 °C, and then kept for 1 h. After it was cooled to room temperature, it was taken out and ground to obtain a carbonized sample of wool. This initial charcoal is added to K according to the mass ratio of 1:4 2 CO 3 The powder is stirred evenly and placed in a tubular reactor for high temperature activation treatment. Heating rate 10℃·min -1 , to the set temperature of 400 ℃, then keep it for 1 h, and then take it out after it cools to room temperature. Wash with distilled water until the pH value of the filtrate is 6.5 to 7, and after drying, the activated carbon with wool as raw material is obtained.

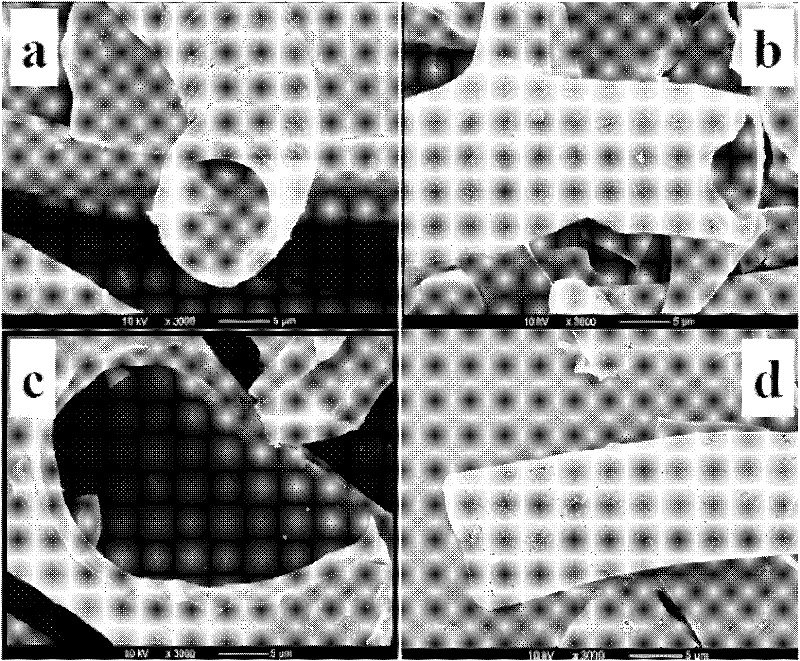

[0022] figure 2 a is the scanning electron microscope images of wo...

Embodiment 2

[0024] When the wool raw material is pyrolyzed, the temperature is raised to the set temperature of 260°C, and then kept for 0.5h. 2 CO 3 The powder is activated and heated to a set temperature of 500° C. and then kept for 90 minutes. The remaining steps and parameters are the same as those in Example 1, and activated carbon with wool as raw material is obtained.

[0025] figure 2 b is the scanning electron microscope image of wool activated carbon prepared by the method described in this example under different magnifications. The electron microscope model used is JEOL NEOSCOPE (JCM-5000). From the figure, we can clearly see that the method of this embodiment is adopted. Prepared activated carbon: A tube was formed in the activated carbon sample, the tube wall was uniform, and a large number of macropores and mesopores were formed on the surface of the tube. According to the determination of its BET specific surface area is 346m 2 ·g -1 , with an average pore volume of 0...

Embodiment 3

[0027] When the wool raw material is pyrolyzed, the temperature is raised to the set temperature of 260°C, and then kept for 0.8h. 2 CO 3 The powder is activated and heated to a set temperature of 600° C. and then kept for 60 minutes. The remaining steps and parameters are the same as those in Example 1 to obtain activated carbon with wool as raw material.

[0028] figure 2 c is the scanning electron microscope image of wool activated carbon prepared by the method described in this example under different magnifications. The electron microscope model used is JEOL NEOSCOPE (JCM-5000). From the figure, we can clearly see that the method of this embodiment is adopted. Prepared activated carbon: A tube was formed in the activated carbon sample, and the tube wall was thinner; however, a "big hole" was "exploded" in the middle of the tube due to the high temperature. According to the determination of its BET specific surface area is 426m 2 ·g -1 , with an average pore volume of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com