Method for synthesizing metal molybdate micron/nano materials by adopting microwave radiation method

A microwave radiation method and nanomaterial technology, which is applied in the field of preparation of functional catalytic materials, can solve problems such as difficulty in structure control, and achieve the effects of wide application range, regular morphology and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

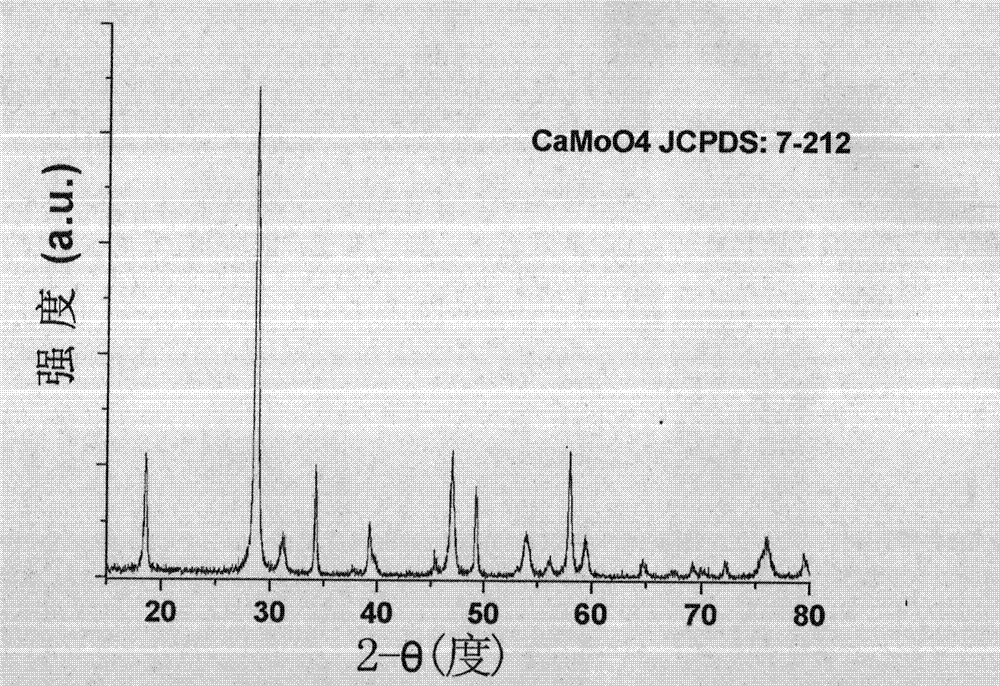

[0029] At room temperature of 25°C, prepare the molar concentration of calcium nitrate aqueous solution to be 0.100mol / L, and then add 0.050mol / L ethylenediaminetetraacetic acid to the solution to make the molar concentration of calcium nitrate and surfactant ethylenediaminetetraacetic acid The ratio is 10:5, stir vigorously for 5 minutes; weigh the ammonium molybdate solid with the molar number equal to the metal cation, add distilled water until it dissolves completely, and obtain a uniform transparent clear solution; then add it dropwise to the metal salt solution, and stir vigorously 5 minutes; the obtained solution is transferred to a glass round bottom flask, and reacted in a microwave irradiation reactor, and the reaction time is 30 minutes, and the ultrafine powder material can be prepared. The ultrafine powder was analyzed by XRD phase ( figure 1 ) indicates that it is CaMoO 4 Pure phase, the corresponding JCPDS card number is 7-212, the space group is I41 / a (No.88),...

Embodiment 2

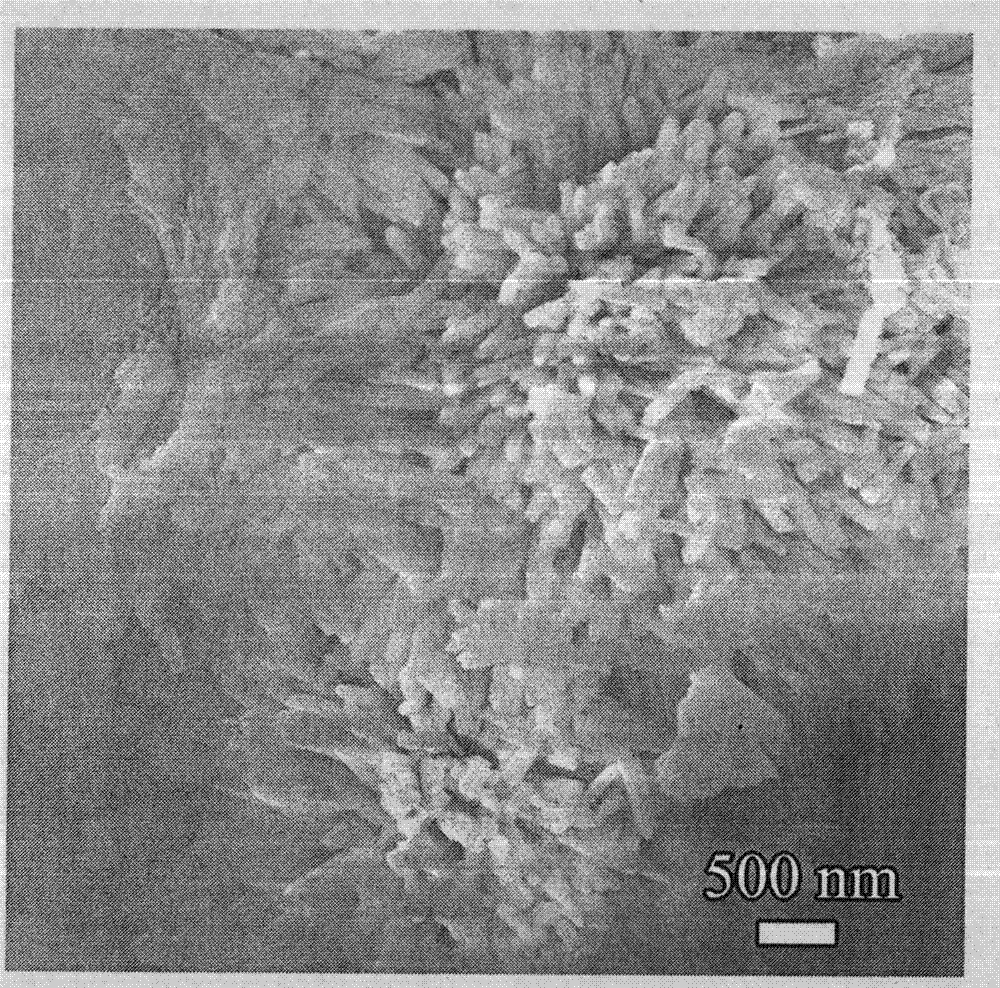

[0031] At room temperature of 25°C, prepare the molar concentration of calcium nitrate aqueous solution to be 1.000mol / L, and then add 0.100mol / L ethylenediaminetetraacetic acid to the solution to make the molar concentration of calcium nitrate and surfactant ethylenediaminetetraacetic acid The ratio is 10:1, stir vigorously for 5 minutes; weigh the ammonium molybdate solid with the molar number equal to the metal cation, add distilled water until it dissolves completely, and obtain a uniform transparent and clear solution; then add it dropwise to the metal salt solution, and stir vigorously 5 minutes; the obtained solution was transferred to a glass round-bottomed flask, and reacted in a microwave irradiation reactor for 30 minutes to prepare a pure-phase calcium molybdate material. The product was scanned by SEM ( image 3 ) shows that the main morphology of the product is nanorods, wherein a small amount of calcium molybdate nanosheets are 500-800 nanometers in diameter and...

Embodiment 3

[0033] At room temperature of 25°C, configure the molar concentration of strontium nitrate aqueous solution to be 0.015mol / L, and then add 0.0015mol / L ethylenediaminetetraacetic acid to the solution to make the molar concentration of calcium nitrate and surfactant ethylenediaminetetraacetic acid The ratio is 10:1, stir vigorously for 5 minutes; weigh the ammonium molybdate solid with the molar number equal to the metal cation, add distilled water until it dissolves completely, and obtain a uniform transparent and clear solution; then add it dropwise to the metal salt solution, and stir vigorously 5 minutes; the obtained solution was transferred to a glass round-bottomed flask, and reacted in a microwave irradiation reactor for 30 minutes to prepare a pure-phase strontium molybdate material. The product was scanned by SEM ( Figure 4 ) shows that it is a nano-sheet structure, the diameter of the sheet-like material is several microns, the thickness of the sheet is 50-80 nm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com