Method for measuring lamina decrement difference value of content of paste-like ink volatile organic compound

A technology of organic compounds and measurement methods, applied in the field of slurry ink detection, to achieve the effects of improving detection efficiency, accuracy, and ensuring the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

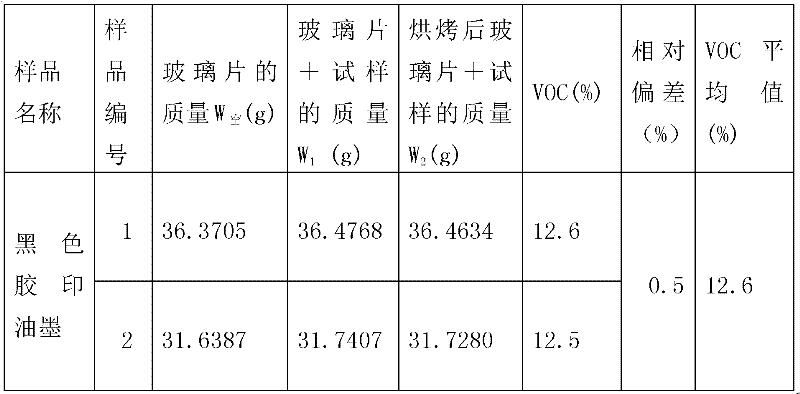

Embodiment 1

[0017] The specific implementation steps of the detection method are as follows:

[0018] First weigh the weight W of the empty glass sheet 空 And record; then use a scraper to evenly pass the sample ink that is 1 to 2 times larger than the leveling amount through the film that has a rectangular window engraved on the glass sheet, and leave a thickness of 0.2mm±0.01mm on the glass sheet through the window Thin layer of sample ink, weighing the weight of the glass W 1 And record; then put the glass piece into the blast oven, bake at the baking temperature of 110°C±2°C for 1 hour; after 1 hour, take out the glass piece; after cooling to room temperature, weigh the baked The weight of the glass sheet W 2 and record;

[0019] Calculated according to the following formula:

[0020] W 1 -W 空 =W 试样 ;

[0021] W 1 -W 2 =W voc ;

[0022] W voc ÷W 试样 =VOC%;

[0023] Carry out the mean value after carrying out twice sample detection calculation respectively; Usually when tw...

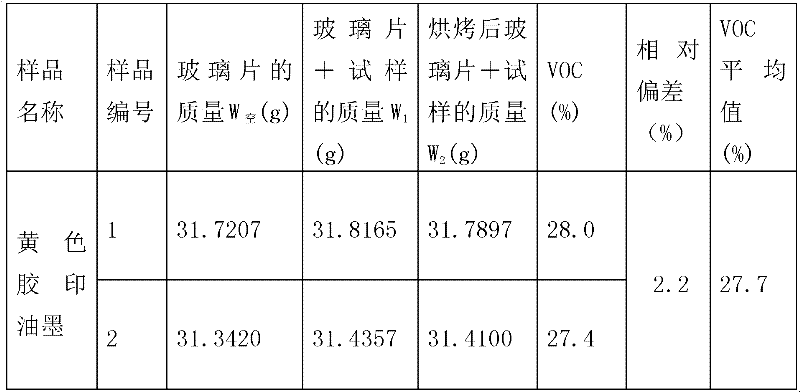

Embodiment 2

[0044] Refer to the detection tools and materials and detection steps of specific embodiment 1.

[0045] Table 2 adopts the yellow offset printing ink produced by a certain manufacturer of the detection method of the present invention

[0046]

[0047] By testing the yellow offset printing ink by this method, the obtained results have good reproducibility, the experimental error is reduced, and the accuracy of analysis is also improved.

[0048] Others are with embodiment 1.

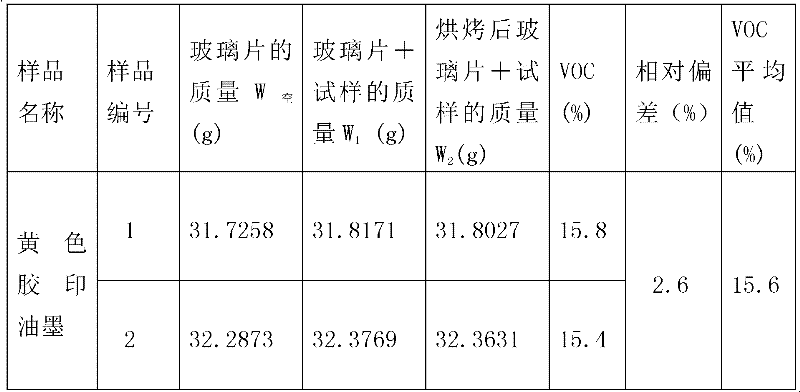

Embodiment 3

[0050] Refer to the detection tools and materials and detection steps of specific embodiment 1.

[0051] The detection method analyzes the yellow offset printing ink produced by a certain manufacturer.

[0052] Table 3 adopts the yellow offset printing ink produced by a certain manufacturer of the detection method of the present invention

[0053]

[0054] By testing the yellow offset printing ink by this method, the obtained results have good reproducibility, the experimental error is reduced, and the accuracy of analysis is improved.

[0055] Others are with embodiment 1.

[0056] This test method can effectively improve production efficiency and quality, ensure safe production, and avoid economic losses. The application effect is very significant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com