Manufacturing process of low-power TOP LED (light-emitting diode) support, and product and LED module thereof

A technology of LED bracket and manufacturing process, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of low-power TOPLED bracket heat dissipation requirements, waste of cost, etc., and achieve the effect of low cost, low cost, and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

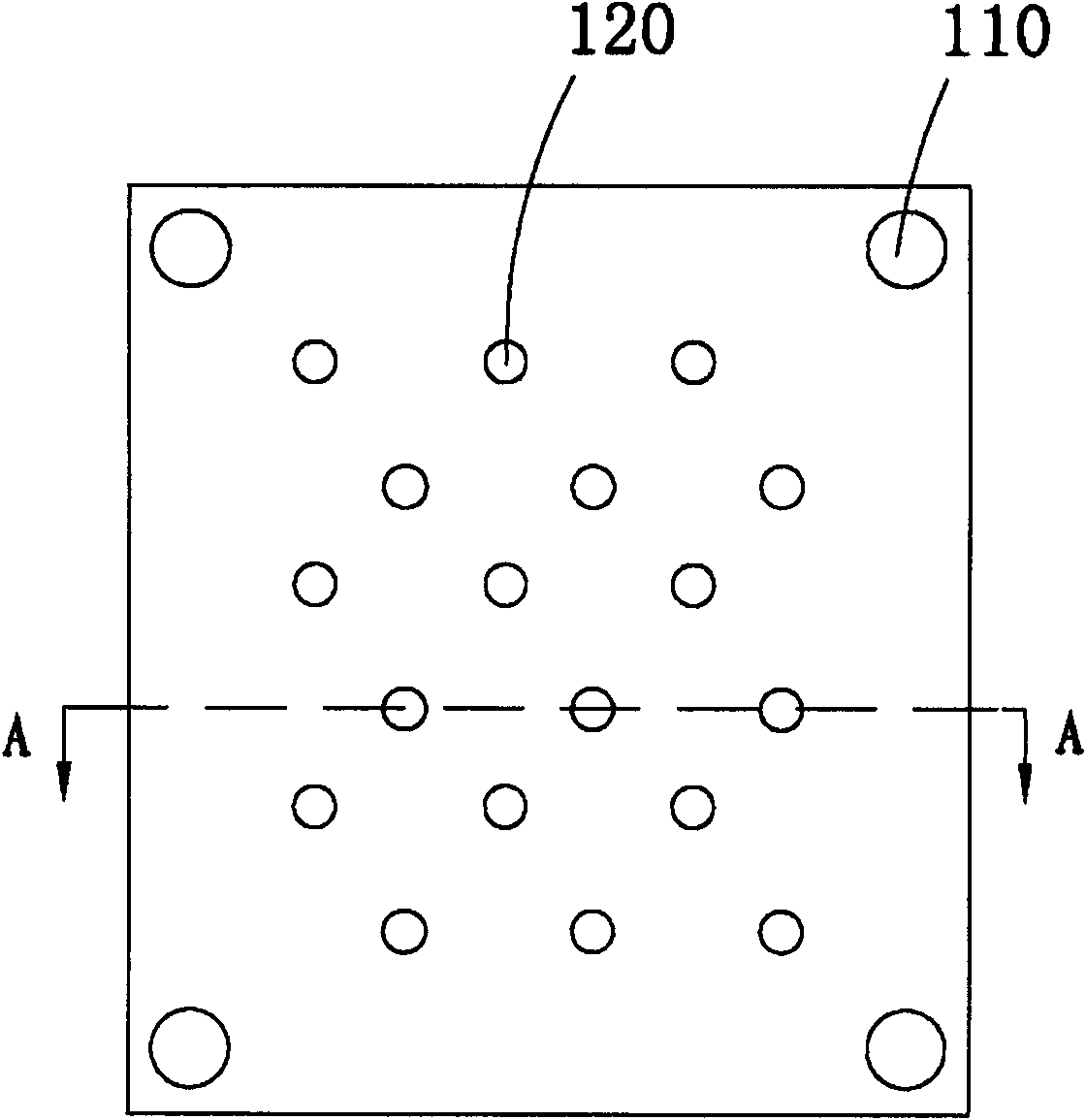

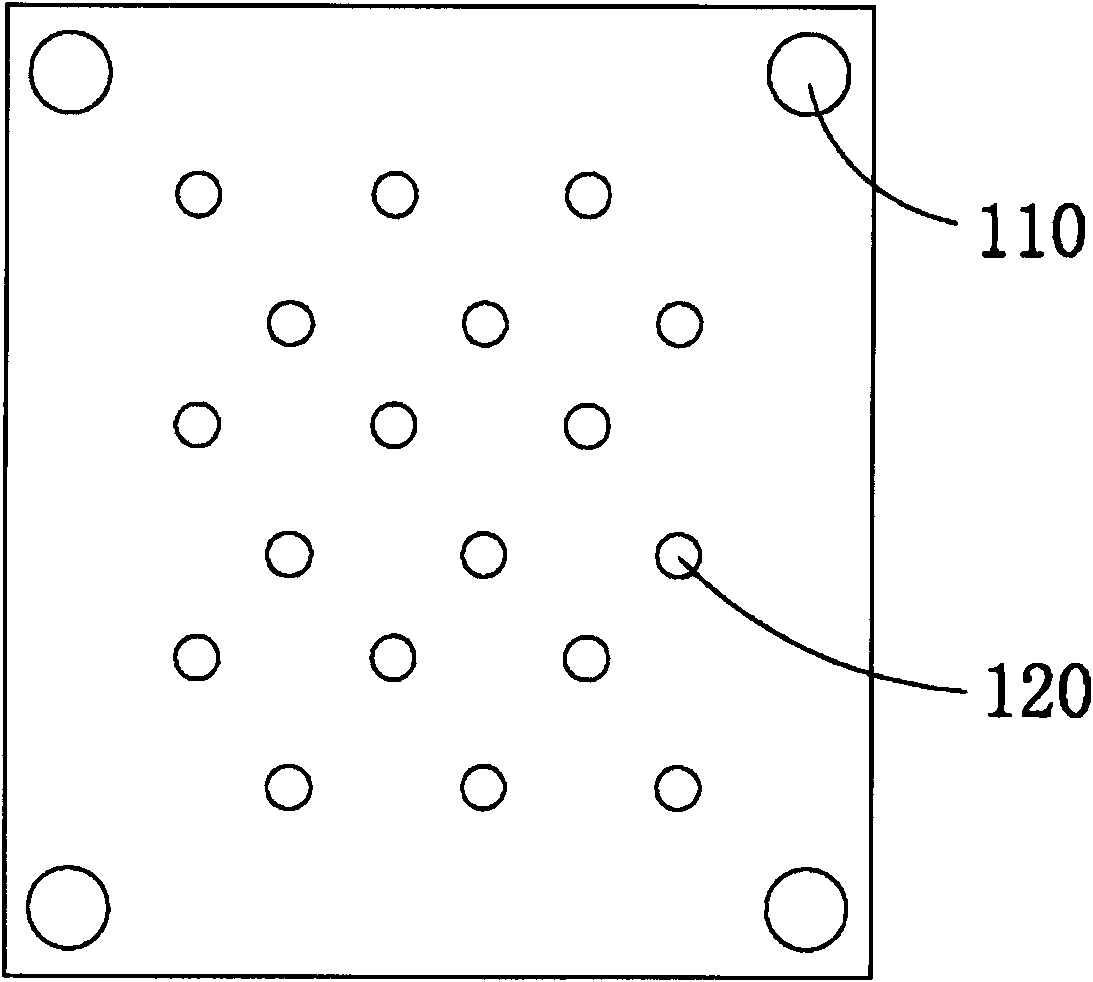

[0036] Further, please refer to FIG. 1 , as an embodiment of the manufacturing process of the low-power TOP LED bracket provided by the present invention, the first step also includes drilling a second through hole 110 for positioning, and the second through hole 110 The aperture of the first through hole 120 is controlled between 1.4-1.6 mm, and the aperture of the first through hole 120 is controlled between 0.78-0.82 mm. The purpose of drilling the second through hole 110 for positioning is that this hole can be used as a design reference, which can be used as a reference in subsequent processes such as electroplating, injection molding, die bonding, wire bonding, and sealing to avoid large errors; the aperture The size must be appropriate, especially the diameter of the first through hole 120 is directly related to the mechanical strength of the substrate. According to tests, the diameter of the first through hole 120 is preferably controlled between 0.78 mm and 0.82 mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com