Control system in wind turbine blades

A technology for wind turbine blades and wind turbines, which is applied in the control of wind turbines, the drive of control systems, and engine control. It can solve the problems of undesired use of cables and poor mechanical stability, and achieve compact and strong structures. Strong, cheap weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

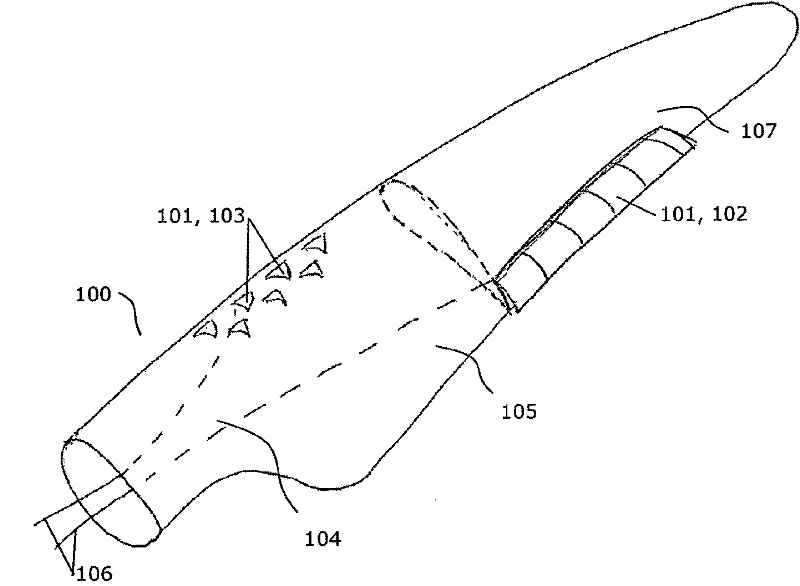

[0050] FIG. 1 shows a prior art wind turbine blade 100 and shows some examples of so-called aerodynamic devices 101 . During wind turbine operation, when the aerodynamic device associated with the blade body 107 is operated, it changes the aerodynamic surface or shape 105 of the wind turbine 100 thereby changing the lift and / or drag coefficient of the wind turbine. In the example shown in the figure, either by changing the position of a movable trailing edge flap 102 disposed at an outer distance along the length of the blade, or by actuating a plurality of movable vortex generators 103 (in this example, vortex The generator is arranged on the suction side of the wind turbine blade close to the root 104 ) and can change and adjust the aerodynamic shape 105 of the wind turbine blade 100 . Examples of such aerodynamic devices 101 are, as described above in the background, different movable or adjustable flaps, such as trailing edge flaps 102, leading edge ailerons or Krueger fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com