Preparation method of nickel nanoparticles-loaded multi-wall carbon nanotube catalytic agent

A multi-walled carbon nanotube, nickel nanoparticle technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of agglomeration, uneven loading, and it is difficult to control the reaction rate of nickel particles Growth environment and other problems, to achieve the effect of fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Carbon tube pretreatment:

[0023] (a) Acidification: Disperse 2g of multi-walled carbon nanotubes in 120ml of mixed acid solution, the volume ratio of concentrated nitric acid (65%): concentrated sulfuric acid (98%)=1:3, reflux at 60°C for 5h, wash with deionized water until Neutral, vacuum dried for 12h.

[0024] (b) Sensitization: Ultrasonic dispersion (40kHz) of 40mg acidified carbon tubes in 40ml containing 0.08g SnCl 2 , 0.1ml 1mol / L HCl and 0.01g PDMA aqueous solution for 30min, filtered, washed with deionized water, and dried in vacuum for 1h.

[0025] (c) Activation: ultrasonically disperse 40mg of sensitized carbon nanotubes in 40ml containing 0.0084g PdCl 2 , 0.48ml1mol / L HCl, 0.01g PDMA aqueous solution for 30min, thoroughly washed with deionized water, and vacuum dried for 24h.

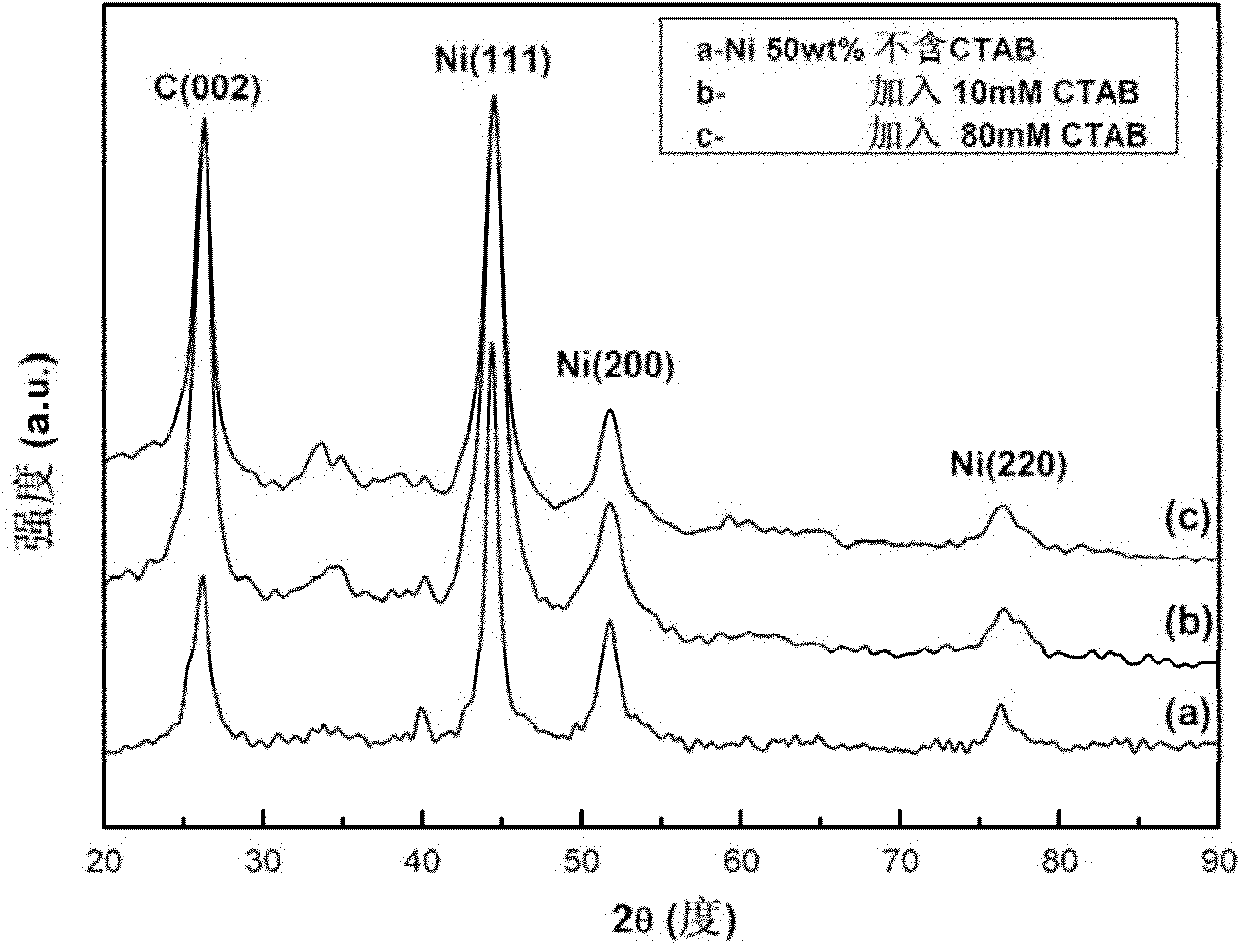

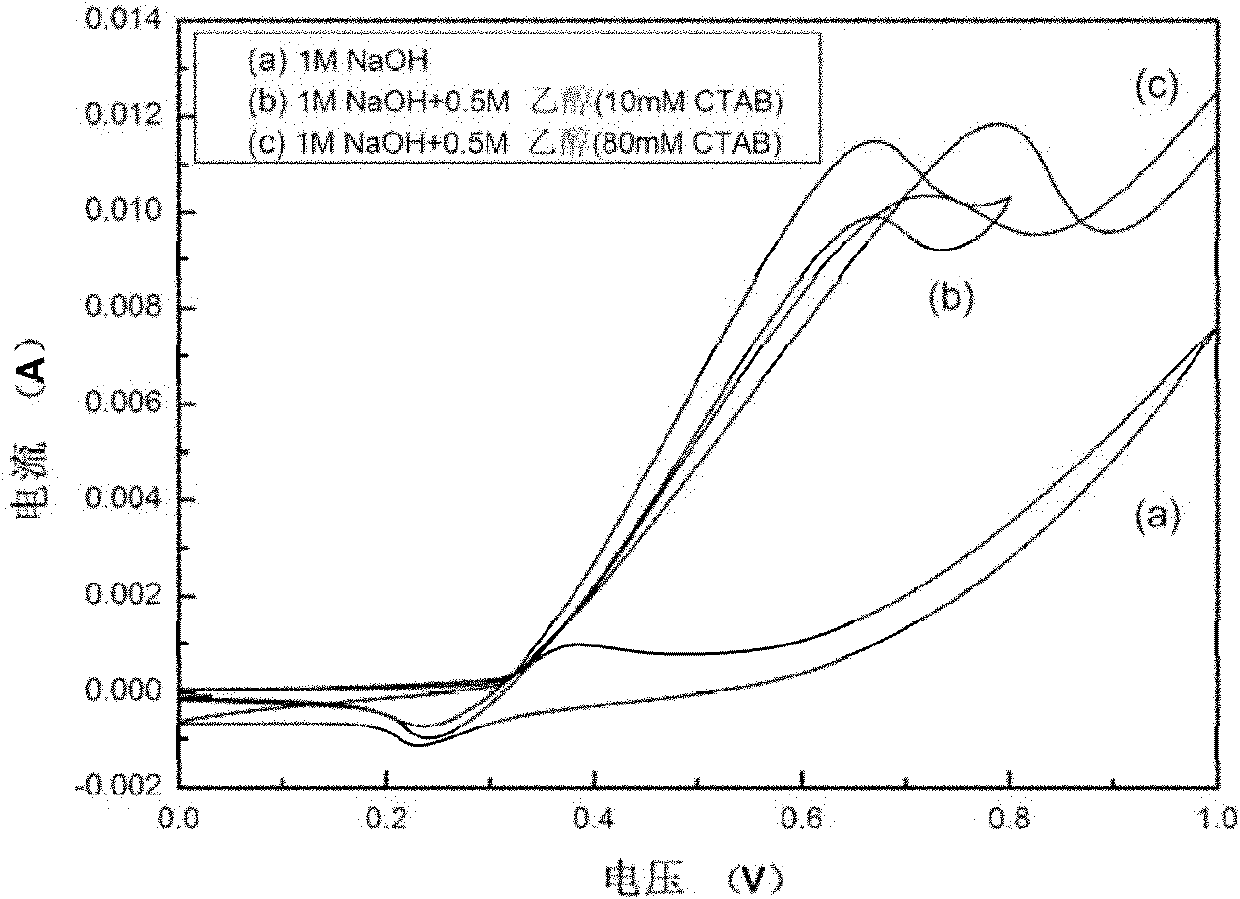

[0026]2) Mix 50 mg of treated multi-walled carbon nanotubes in 50 ml of aqueous solution, add 0.101 g of NiCl according to 50 wt % nickel loading 2 ·6H 2 O, and 0.182g (10m...

Embodiment 2

[0030] 1) Carbon tube pretreatment:

[0031] (a) Acidification: Disperse 3g of multi-walled carbon nanotubes in 120ml of mixed acid solution, the volume ratio of concentrated nitric acid (65%): concentrated sulfuric acid (98%)=1:3. Condensate and reflux at 80°C for 6h, wash with deionized water until Neutral, vacuum dried for 12h.

[0032] (b) Sensitization: Ultrasonic dispersion (40kHz) of 60mg acidified carbon tubes in 60ml containing 0.12g SnCl 2 , 0.15ml 1mol / L HCl and 0.03g PDMA aqueous solution for 30min, filtered, washed thoroughly with deionized water, and dried in vacuum for 1h.

[0033] (c) Activation: ultrasonically disperse 60mg of sensitized carbon nanotubes in 60ml containing 0.0126g PdCl 2 , 0.72ml 1mol / L HCl, 0.03g PDMA aqueous solution for 30min, rinse thoroughly with deionized water, and vacuum dry for 24h.

[0034] 2) Mix 50 mg of treated multi-walled carbon nanotubes in 50 ml of aqueous solution, add 0.101 g of NiCl according to 50 wt % nickel loading 2...

Embodiment 3

[0038] 1) Carbon tube pretreatment:

[0039] (a) Acidification: Disperse 2g of multi-walled carbon nanotubes in 100ml of mixed acid solution, the volume ratio of concentrated nitric acid (65%): concentrated sulfuric acid (98%)=1:3. Condensate and reflux at 60°C for 8h, wash with deionized water until Neutral, vacuum dried for 12h.

[0040] (b) Sensitization: Ultrasonic dispersion (40kHz) of 40mg acidified carbon tubes in 20ml containing 0.04g SnCl 2 , 0.05ml 1mol / L HCl and 0.005g PDMA aqueous solution for 30min, filtered, washed thoroughly with deionized water, and dried in vacuum for 1h.

[0041] (c) Activation: ultrasonically disperse 40mg of sensitized carbon nanotubes in 20ml containing 0.0042g PdCl 2 , 0.24ml1mol / L HCl, and 0.005g PDMA aqueous solution for 30min; thoroughly wash, vacuum dry for 24h, thoroughly wash with deionized water, and vacuum dry for 24h.

[0042] 2) Mix 50 mg of treated multi-walled carbon nanotubes in 50 ml of aqueous solution, add 0.101 g of Ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com