Manufacture technology of telescopic and elastic piston oil seal

A manufacturing process, elastic piston technology, applied in the field of oil seal manufacturing process, can solve the problems of short service life, insufficient clearance compensation, large resistance and easy wear, etc., to achieve improved service life, small frictional resistance, and thin single-layer lip wall Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

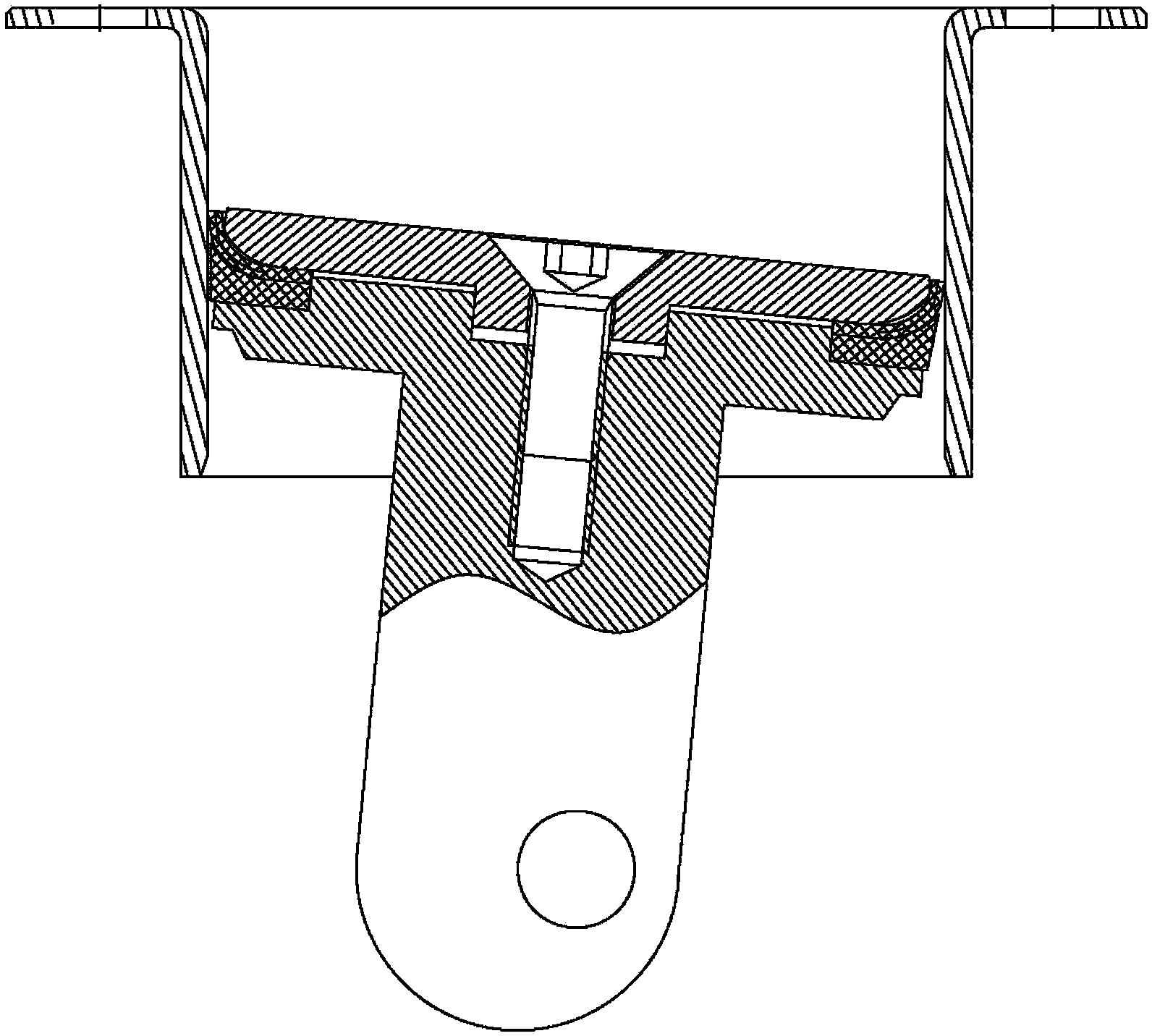

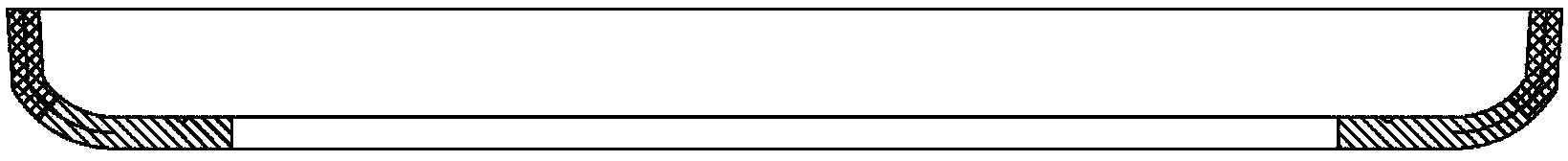

Image

Examples

Embodiment 1

[0024] 1. Material preparation, the raw materials of oil seal are divided into raw material A and raw material B, raw material A is pure polytetrafluoroethylene, raw material B is a mixture composed of polytetrafluoroethylene and filler, wherein, based on the weight of raw material B, raw material B is polytetrafluoroethylene Tetrafluoroethylene is 80%; glass fiber is 15%; polyether ether ketone is 2.5%; copper is 2.5%;

[0025] 2. Mold molding. After the batching is completed, raw material A is added to the first mold for compression molding. During the pressing process, the pressure is controlled at 0.25MPa ~ 0.7Mpa. At this time, raw material A is pressed into a bar blank;

[0026] 3. Forming again, put the raw material A bar blank that is pressed and formed in step 2 into the second mold, and then fill the corresponding quality of raw material B around the raw material A bar blank, and press it to form a raw material blank. During the process, the pressure is controlled at...

Embodiment 2

[0032] 1. Material preparation, the raw materials of oil seal are divided into raw material A and raw material B, raw material A is pure polytetrafluoroethylene, raw material B is a mixture composed of polytetrafluoroethylene and filler, wherein, based on the weight of raw material B, raw material B is polytetrafluoroethylene Tetrafluoroethylene is 80%; glass fiber is 3%; carbon fiber is 6%; copper is 4%; polyether ether ketone is 7%;

[0033] All the other steps are the same as in Example 1.

Embodiment 3

[0035] 1. Material preparation, the raw materials of oil seal are divided into raw material A and raw material B, raw material A is pure polytetrafluoroethylene, raw material B is a mixture composed of polytetrafluoroethylene and filler, wherein, based on the weight of raw material B, raw material B is polytetrafluoroethylene Tetrafluoroethylene is 95%; polyether ether ketone is 3%; copper is 2%;

[0036] All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com