Metallocene polyethylene greenhouse film resin composition

A technology of metallocene polyethylene and resin composition, applied in the field of polyethylene resin composition for greenhouse film, can solve the problems such as the inability to guarantee the excellent physical properties of mLLDPE, the inability to guarantee the stability of the quality of the film product, and the complexity of the metallocene polyethylene method. , to achieve the effect of significant resin reinforcement, increase cost and improve processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] The preparation method of the metallocene polyethylene greenhouse film resin composition: the base resin mLLDPE is used as 100 parts by weight, and the parts added by other additives are used as parts by weight.

[0046] 1) Specific raw material formula and preparation process. See Table 1 and Table 2.

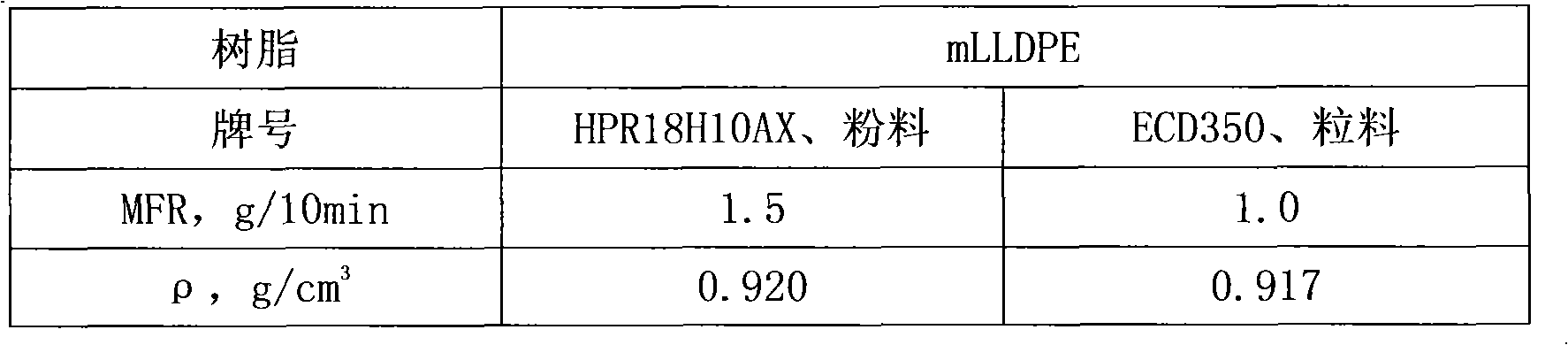

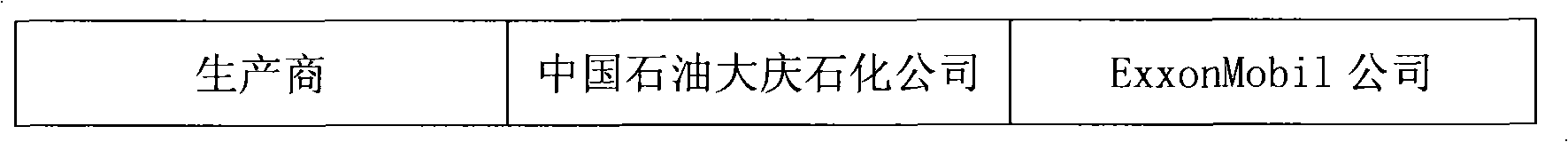

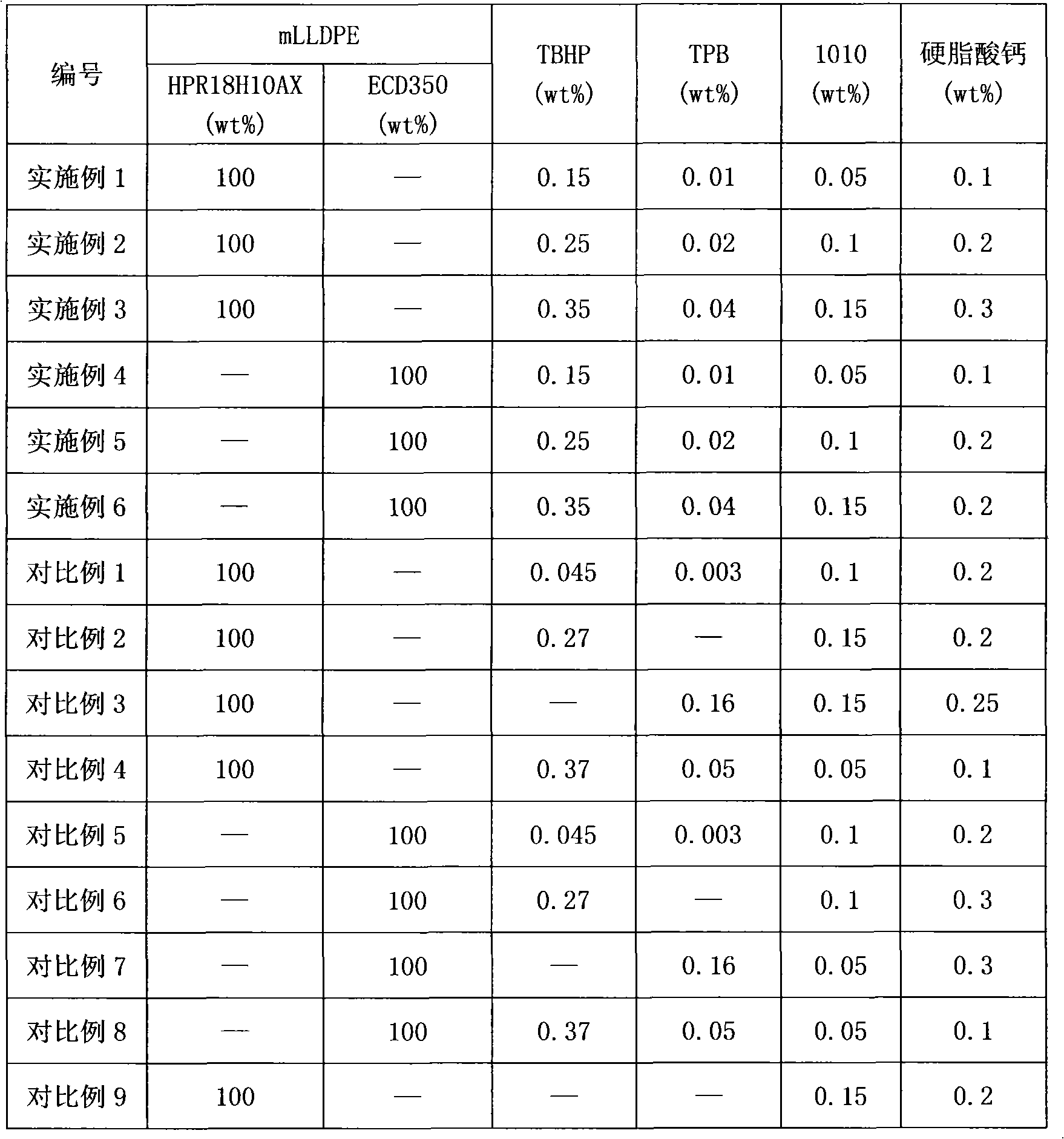

[0047] Table 1 raw material formula

[0048]

[0049] Table 2 Twin-screw extruder preparation process

[0050]

[0051]

[0052] 2) The blowing and performance of the shed film. see table 3

[0053] Table 3 Resin Composition Blowing Process Conditions for Shed Film*

[0054]

[0055]

[0056] *Φ120 three-layer composite blown film unit provided by Dalian Rubber and Plastic Machinery Factory

[0057] 3) The test results of the performance of the greenhouse film resin composition and the application performance of the greenhouse film. See Table 4 and Table 5.

[0058] The physical property of table 4 resin composition

[0059]

[0060]

[0061...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com