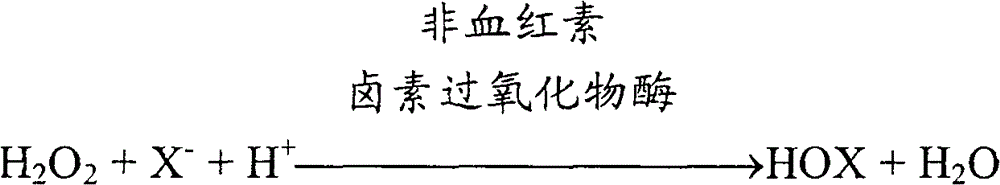

Enzymatic production of peracids from carboxylic acid ester substrates using non-heme haloperoxidases

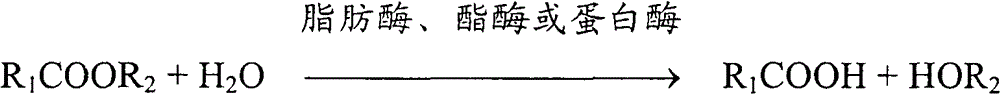

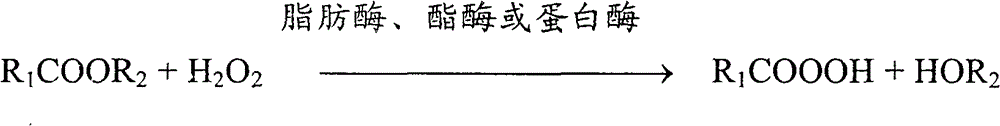

一种催化制备、过酸的技术,应用在有机过/无机过化合物组合物、氧化还原酶、植物学设备和方法等方向,能够解决不能满足、过酸浓度降低、过酸不稳定等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0151] Cloning of 5B non-heme haloperoxidase from Pseudomonas putida

[0152] A series of PCR primers were designed based on published non-heme haloperoxidase sequences from Pseudomonas putida strains including KT2440, IF-3 and MR-2068 (respectively, 26991929, 6451702 and 1360922). PCR using genomic DNA from Pseudomonas putida 5B (NRRL-18668) with primer #1 (5-GATCTGG TCATCGTCGCCATGCATCAC-3'; SEQ ID NO: 1) and primer #2 (5'-GCCGA CGACTGGGACGCGCAGATG-3'; SEQ ID NO: 2) and with primer #1 and primer #3 (5'-ATGAGCTACGTCACCACCAAAGATGG-3'; SEQ ID NO: 3) generated approximately 600 bp and 700 bp products, respectively. The nucleotide sequences (SEQ ID Nos: 4 and 5) and the corresponding deduced amino acid sequences of these products were confirmed to be partially identical to non-heme haloperoxidase genes. Genome sequencing with primer #4 (5'-GGCTACGTCGTCGGCATAGTGGTC-3'; SEQ ID NO: 6) revealed the presence of a Pst| restriction site several hundred bp upstream of the non-heme ha...

Embodiment 2

[0154] Expression of Pseudomonas putida 5B non-heme haloperoxidase in Escherichia coli

[0155] The non-heme haloperoxidase from Pseudomonas putida 5B was used with primer #7 (5'-G AATTCATGAGCTATGTAACCACGAAGGACGGC-3'; SEQ ID NO: 11) and primer #8 (5'-GCGGCCGCTTAACTACGGATAAACGCCAGCAAATCCGCAT-3'; SEQ ID NO: 12) was amplified by PCR and subcloned into pTrcHis2- (Invitrogen) and 4- (Invitrogen) to generate expression plasmids pSW167 and pSW169, respectively. In addition, the EcoR| fragment from pSW169 was subcloned into pET-28a (Novagen; Madison, Wl) to generate expression plasmid pSW174. E. coli TOP10 (Invitrogen) was transformed with pSW167 or pSW169 to generate strains TOP10 / pSW167 and TOP10 / pSW169, respectively. E. coli BL21(DE3) (Novagen) was transformed with pSW174 to generate strain BL21 / pSW174. 5B non-heme haloperoxidase was expressed in TOP10 / pSW167, TOP10 / pSW169 and BL21 / pSW174 according to Invitrogen's expression protocol. Basically, at 0D 600 Cells were induc...

Embodiment 3

[0157] Agrobacterium tumefaciens (A. tumefaciens) non-heme haloperoxidase ( 16119616) expression in Escherichia coli

[0158] The non-heme haloperoxidase gene from Agrobacterium tumefaciens C58 ("C58") ( 16119616; also referred to herein as "AtuA1"; SEQ ID Nos: 13-14) was used with primer #9 (5'-ATGG GCTTCGTAACAACCAAGGACGGCAC-3'; SEQ ID NO: 15) and primer #10 (5'-TCAGCCCTTGATGAAGGCTAGCAGGTCCTG-3 '; SEQ ID NO: 16) was PCR-amplified and subcloned into 4- (Invitrogen) to generate the pSW166 plasmid. In addition, the EcoR| fragment from pSW166 was subcloned into pET-28a (Novagen) to generate expression plasmid pSW175. E. coli TOP10 (Invitrogen) was transformed with pSW166 to generate strain TOP10 / pSW166. E. coli BL21(DE3) (Novagen) was transformed with pSW175 to generate strain BL21 / pSW175. Pass C58 non-heme haloperoxidase at OD 600 Expression in TOP10 / pSW166 and BL21 / pSW175 was induced with 1 mM IPTG at =0.5-0.6 for 3 hr at 37°C with shaking. SDS-PAGE analysis co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com