Optimized cold spraying method for saving helium

A cold spray, helium technology, applied in spray device, liquid spray device, pressure inorganic powder coating and other directions, can solve problems such as constraints, and achieve the effect of reducing experimental cost and saving He dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

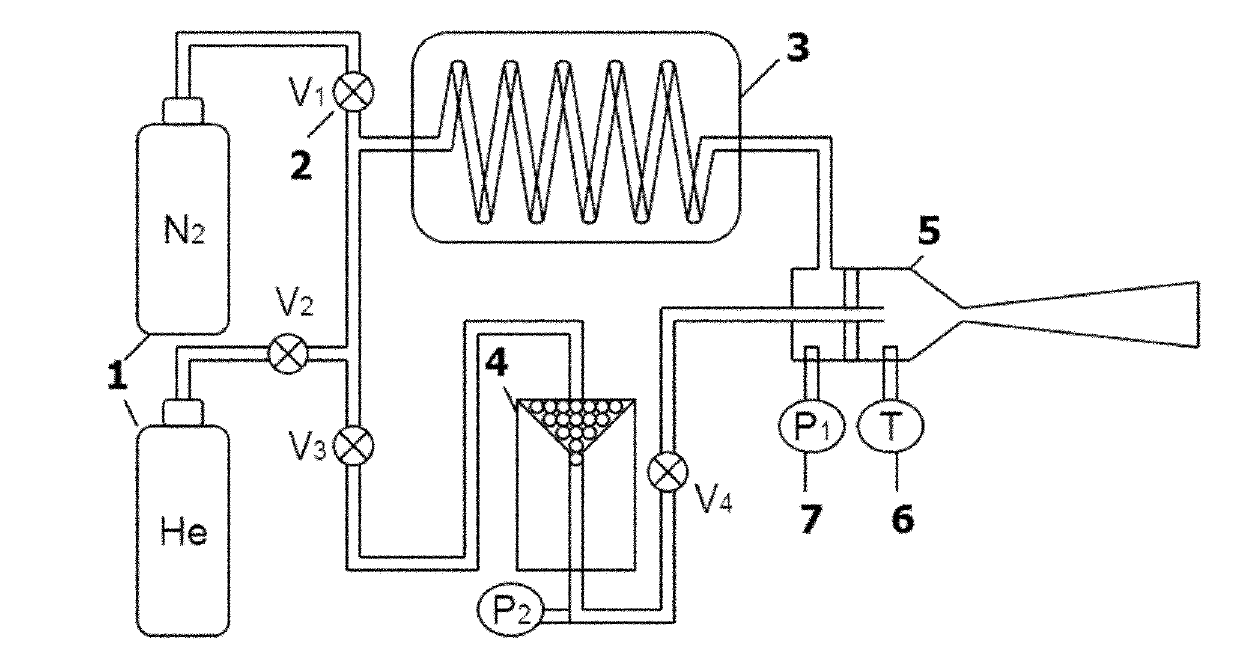

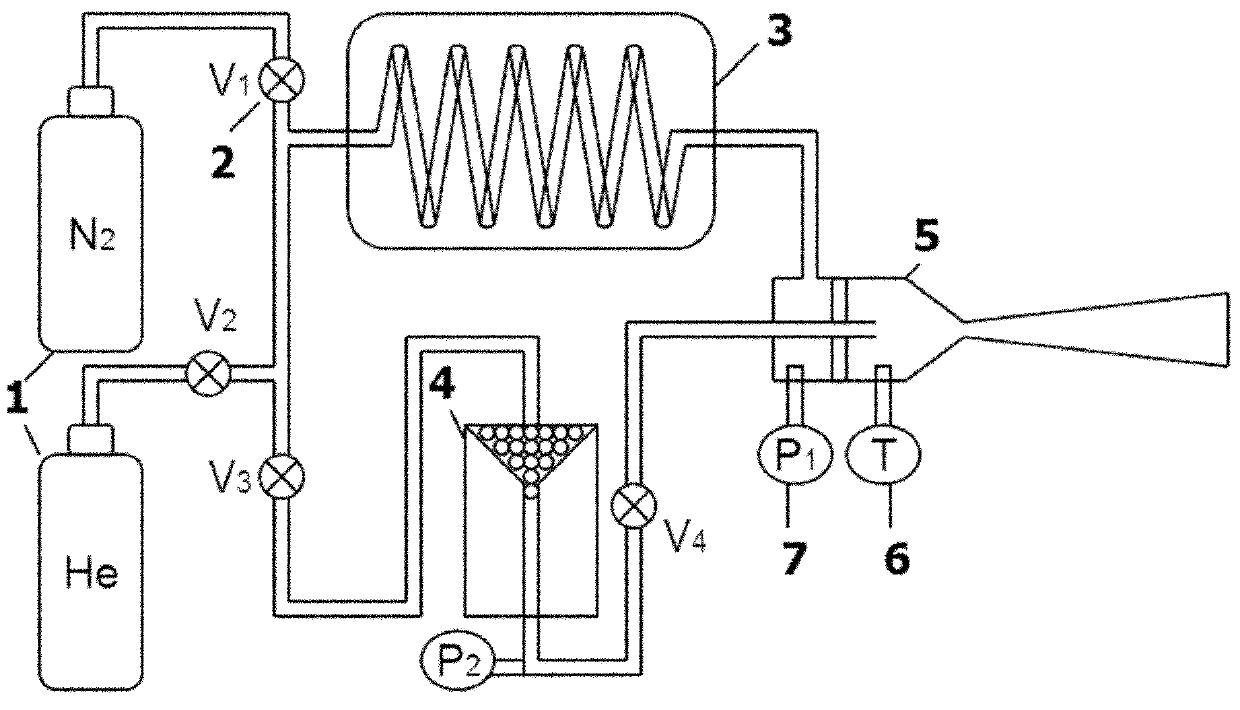

[0019] Such as figure 1 As shown, the application device of this embodiment includes: a high-pressure gas storage tank 1, a control valve 2, a high-frequency heating device 3, a powder tank 4, a supersonic Laval zoom spray gun 5, a thermometer 6 and a pressure gauge 7, wherein: two parallel Helium and nitrogen are respectively stored in the high-pressure gas storage tank 1, the input and output ends of the high-frequency heating device 3 and the powder tank 4 are respectively connected with the high-pressure gas storage tank 1 and the supersonic Laval zoom spray gun 5, the thermometer 6 and the pressure gauge 7 Set on the supersonic Laval zoom spray gun 5, the controllable valve 2 is set in the pipeline and can be opened and closed according to the process requirements.

[0020] The matrix material selected in this example is Al6061 alloy in T6 state, the powder particles are pure Al with an average diameter of 58 μm, and the preheating gas is high-pressure N 2 ; The working ...

Embodiment 2

[0023] The matrix material selected in this embodiment is cast AZ91D magnesium alloy, and the powder particles are Al7075 alloy with an average diameter of 23.3 μm and a shape close to spherical. Both the preheating gas and the working gas are nitrogen, and the pressure and temperature of the working gas are respectively set to 1500Kpa and 280°C. Before the coating is deposited, the surface of the substrate needs to be sandblasted to improve the surface roughness, and then the surface is cleaned with acetone and dried. Take an appropriate amount of Al7075 powder and place it in the powder tank, close the V 2 , V 3 and V 4 valve, opens and regulates V 1 Valves and high-frequency gas heating device, so that the pressure gauge P 1 The reading is controlled at around 1500Kpa. When the reading of the thermometer T rises to 280°C, open and adjust V 3 valve so that P 2 The reading is 1580Kpa, at this time, open the valve V 4 , the moving speed of the spray gun is 2mm / s, and th...

Embodiment 3

[0025] The powder material used in this example is the same as that in Example 1. The base material used is a SUS303 stainless steel base. Before the coating is deposited, the surface of the base needs to be sandblasted to improve the surface roughness, and then the surface is cleaned with acetone and dried. Using the same spraying process parameters as in Example 1, a pure aluminum coating can be prepared on a stainless steel substrate. The resulting coating thickness is about 900 μm and the porosity is less than 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com