Aluminum electrolysis anode device and preparation method thereof

A technology of aluminum electrolysis anodes and anode steel claws, which is applied in the manufacture of tools and ceramic molding machines, etc., can solve the problems of shortening the service life of aluminum electrolysis anode devices, damage to the health of operators, and polluting the atmospheric environment. Energy saving and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described with reference to the accompanying drawings and examples.

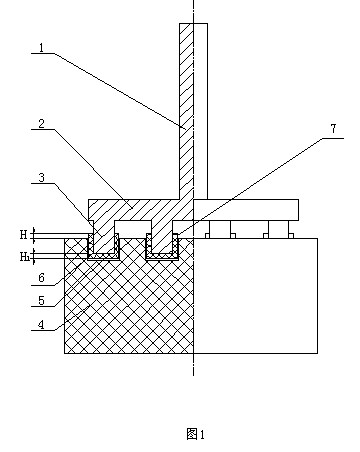

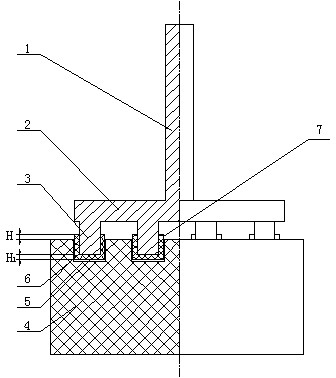

[0014] The present invention reaches the advantages described in the present invention in order to accomplish the object of the invention, and the embodiment in the technical scheme that provides is: as figure 1 As shown, 4 in the figure is an anode carbon block, a carbon bowl 5 is provided on the top of the anode carbon block 4, and the anode steel claw 3 is placed in the carbon bowl 5, and the cavity between the carbon bowl 5 and the anode steel claw 3 is filled with carbon material 6 , The weight ratio of raw materials used in the carbon material 6 is: artificial graphite 45-80, metal shavings 5-40 and resin binder 15-20. The preferred weight ratio of raw materials used in the carbon material 6 of the present invention is: artificial graphite 55-75, metal scrap 10-30 and resin binder 15-20. The resin binder can be powder, liquid or semi-dry powder. Resin bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com