Fragrant thermal fabric manufacture method

A processing method and fragrance technology, applied in melt spinning, fabrics, textiles, etc., can solve the problems of low washability of clothes, poor fragrance persistence, and difficulty in meeting people's wearing needs, so as to improve mechanical strength and Washability, good air permeability, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

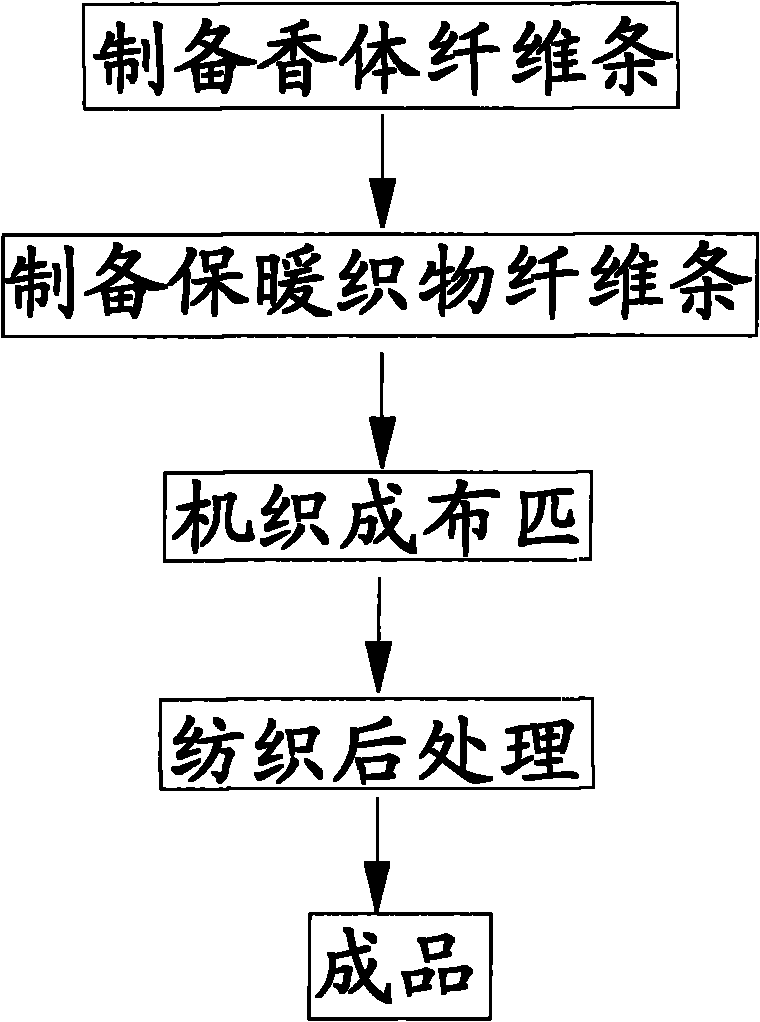

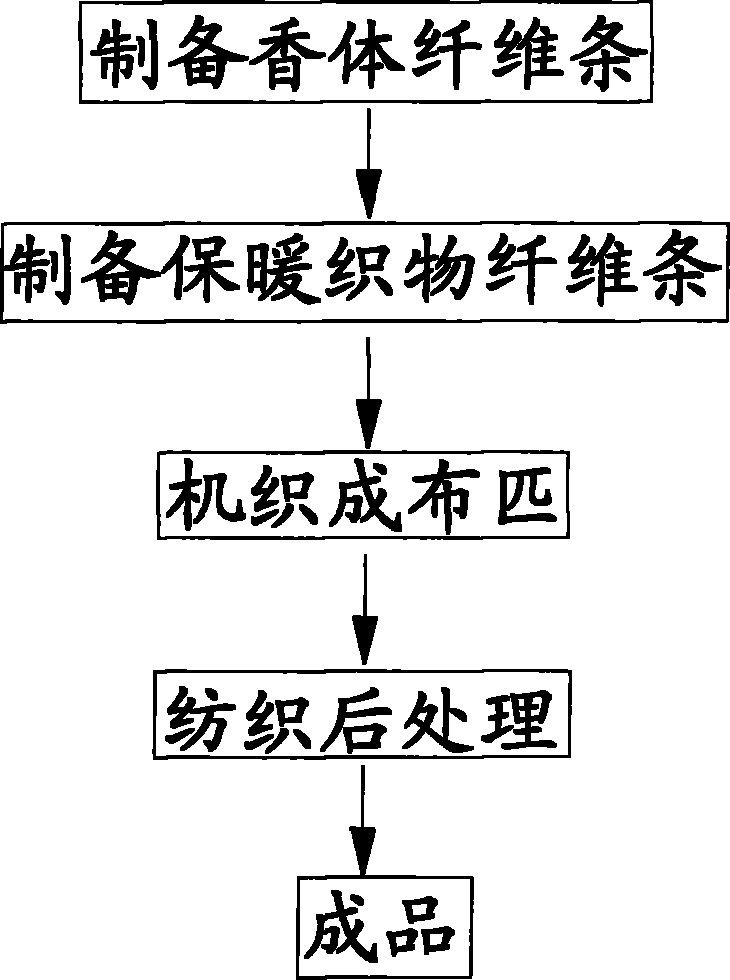

Image

Examples

Embodiment 1

[0019] The specific preparation process of the fabric is as follows:

[0020] a) To prepare scented fiber strips, first, the slow-release microcapsules and synthetic fibers are melt-spun to obtain mixed yarn fibers, wherein the synthetic fibers are polyester fibers, and the percentage of slow-release microcapsules and synthetic fibers is The ratio is: 13%: 87%,

[0021] The specific implementation steps of the melt spinning method described therein are as follows:

[0022] 1) Heat and dry raw materials (sustained-release microcapsules and polyester fibers);

[0023] 2) Melting slow-release microcapsules into synthetic fibers to obtain spinning fluid;

[0024] 3) At a temperature of 200° C. and a pressure of 0.9 MPa, the molten spinning fluid is extruded from the spinneret hole, passed through an aqueous solution cooling medium, and solidified to obtain a mixed yarn fiber.

[0025] Then, the obtained mixed yarn fibers are twisted to obtain low-twisted single-thread yarns.

...

Embodiment 2

[0030] The specific preparation process of the fabric is as follows:

[0031] a) To prepare scented fiber strips, at first, the slow-release microcapsules and synthetic fibers are made into mixed yarn fibers by melt spinning, wherein the synthetic fibers are nylon 66 fibers, and the percentage of slow-release microcapsules and synthetic fibers is The content ratio is: 15%: 85%,

[0032] The specific implementation steps of the melt spinning method described therein are as follows:

[0033] 1) Heat and dry raw materials (sustained-release microcapsules and polyester fibers);

[0034] 2) Melting slow-release microcapsules into synthetic fibers to obtain spinning fluid;

[0035] 3) At a temperature of 210° C. and a pressure of 1.1 MPa, the molten spinning fluid is extruded from the spinneret hole, passed through an aqueous solution cooling medium, and solidified to obtain a mixed yarn fiber.

[0036] Then, the obtained mixed yarn fibers are twisted to obtain low-twisted single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com