Special mining suction drill for coal mine

A technology for coal mines and drill pipes, which is applied in the direction of drill pipes, drill pipes, and drilling equipment. It can solve the problems of large equipment volume, environmental pollution, and difficult installation and transportation, and achieve the effect of convenient disassembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

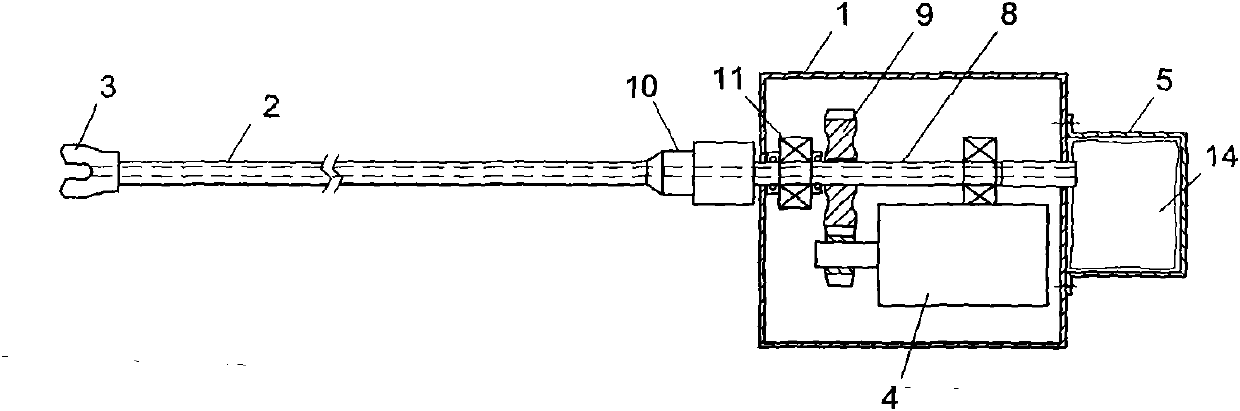

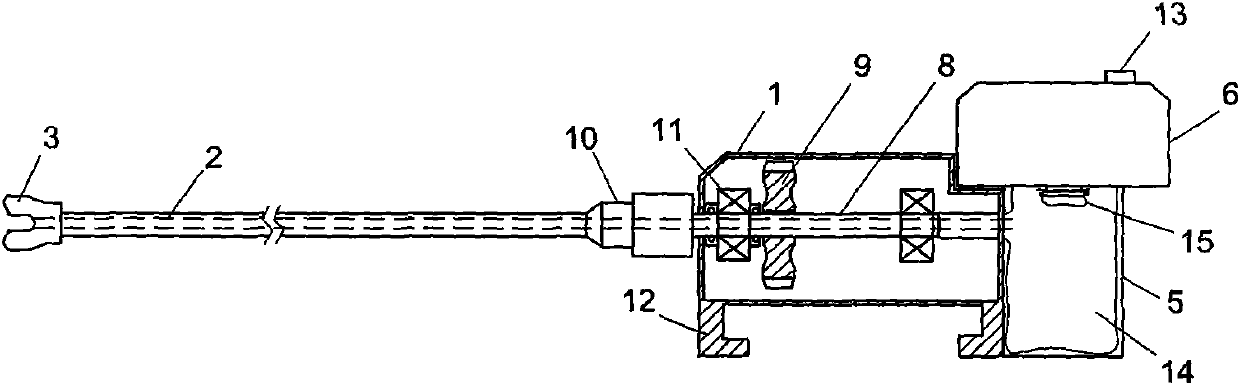

[0017] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 , a special suction drill for coal mines, including a drill rod 2, a drill bit 3, a motor 4 installed in a housing 1, the housing is fixed on a bracket 12, the motor drives a hollow shaft 8 through a gear, and one end of the hollow shaft passes through a clamp and the drill rod Connect, the other end communicates with the exhaust chamber 5 through the connecting pipe, the motor 6 of the exhaust chamber is located at the upper side, the exhaust port is located at the top of the room, and the air outlet 13 is located outside. One deck dust bag 14 is set in the exhaust chamber, and the edge of the dust bag is matched with the edge of the exhaust chamber to facilitate regular dust removal and replacement. The air outlet in the exhaust chamber is covered with a filter screen 15, which can effectively reduce the pollution to the environment.

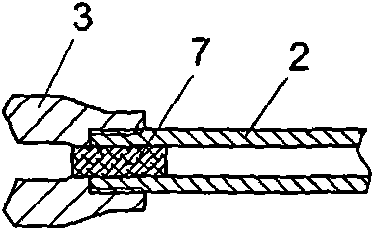

[0018] A filter element 7 is set in the cavity close to the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com