Device and method for continuously measuring working fluid level depth of oil well and continuously metering produced liquid

A technology of metering device and dynamic liquid surface, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc. It can solve the problems of large artificial measurement errors, difficult data acquisition in time, synchronization, accuracy and reliability, and large engineering volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

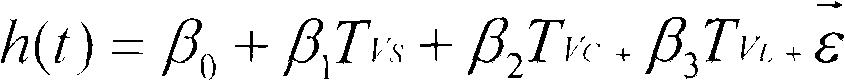

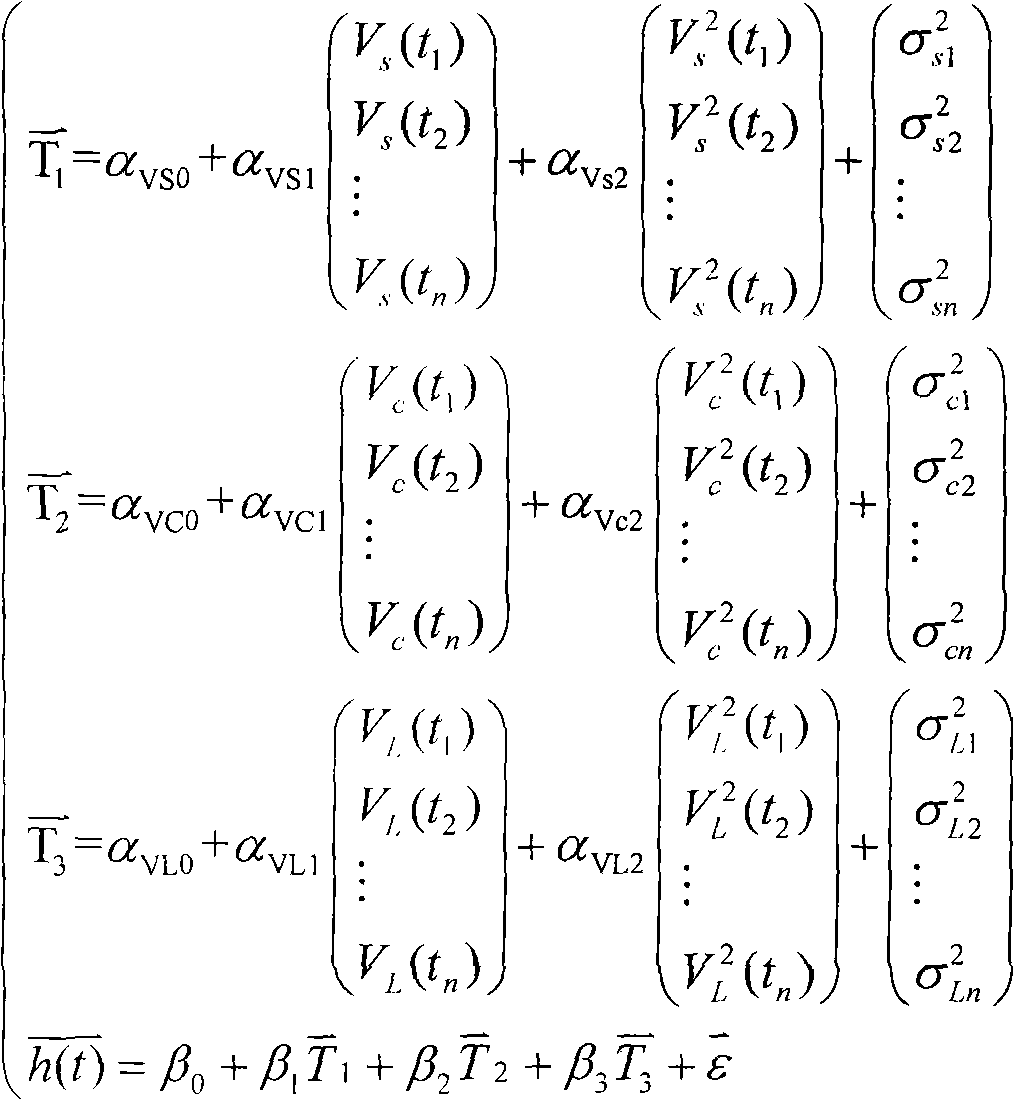

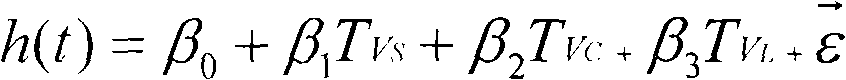

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1, with reference to attached figure 1 and 3 , consists of three parts: a pressure detection module, a signal transmission module 12, and a ground supporting module 13. Each detection unit of the pressure detection module is placed in a certain position in the annular space of the oil jacket, which is composed of 0# (14), 1# (16), and 2# (18) pressure detection units; 0# pressure detection unit 14 is placed in the oil jacket Annular space E zone, measure natural gas pressure sleeve pressure in E zone. When the optical fiber pressure detection method is adopted: the 1# pressure detection unit 16 is placed on the lower edge of the oil well pump body 4; the 2# pressure detection unit 18 is placed on the lower edge of the liner pipe screen assembly 17 of the oil well pump. The signal transmission module 12 is composed of optical cables. The ground supporting module 13 is mainly composed of a trigger unit 20 at the top and bottom dead center of the pumping unit...

Embodiment 2

[0077] Embodiment 2, with reference to attached figure 2 and 3 , consists of three parts: a pressure detection module, a signal transmission module 12, and a ground supporting module 13. Each detection unit of the pressure detection module is placed in a certain position in the annular space of the oil jacket, which is composed of 0# (14), 1# (16), and 2# (18) pressure detection units; 0# pressure detection unit 14 is placed in the oil jacket Annular space E zone, measure natural gas pressure sleeve pressure in E zone. When using the electronic pressure detection method: 1#16 and 2#18 pressure detection units are respectively placed at a certain depth below the initial liquid level. The recommended positions are 50 meters and 100 meters. The signal transmission module 12 is composed of cables. The ground supporting module 13 is mainly composed of a trigger unit 20 at the top and bottom dead center of the pumping unit, a signal transceiver unit 19, a data processing and sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com