Filling supporting partition board bracket

A technology of partitions and baffles, applied in the direction of pillars/brackets, fillings, mining equipment, etc., can solve the problem that the goaf cannot be divided into small areas, and achieve the effect of enhancing stability and expanding the range of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below through embodiments in conjunction with the accompanying drawings.

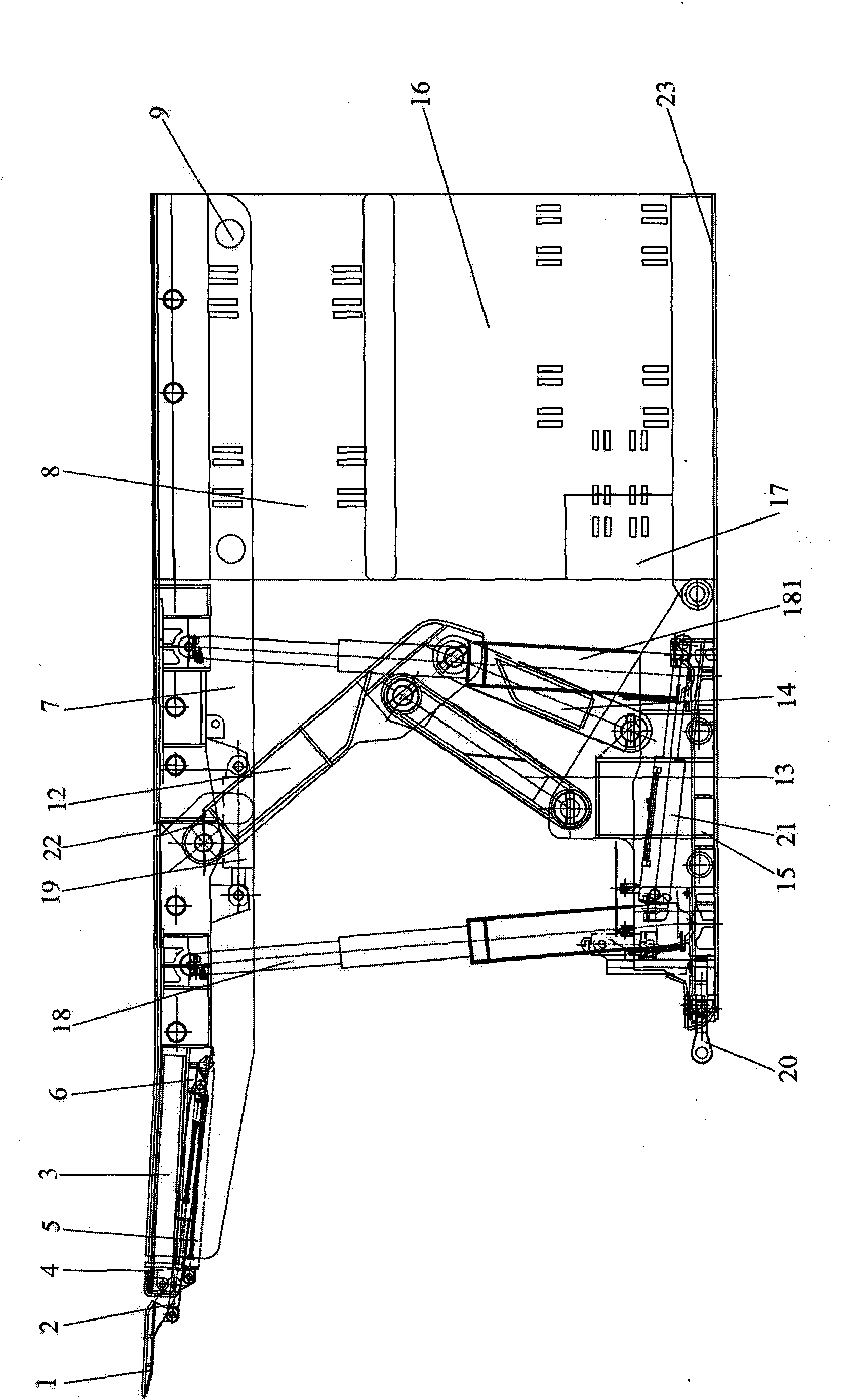

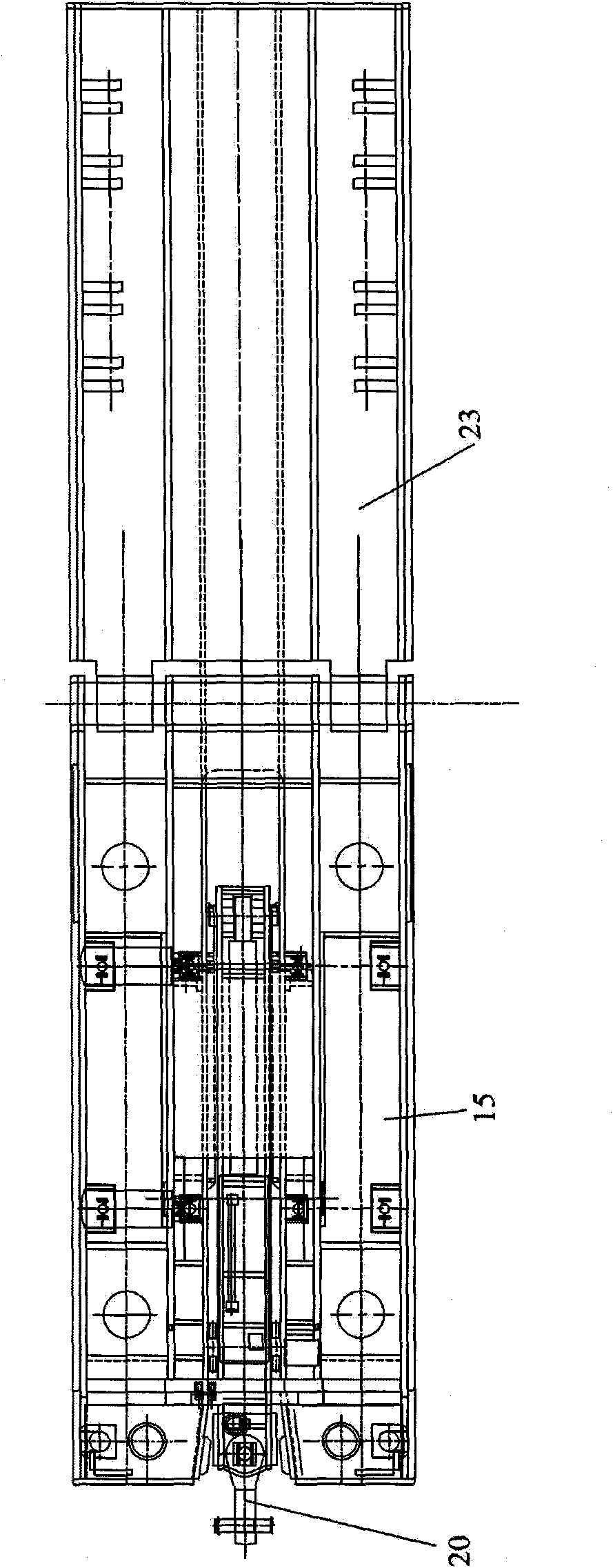

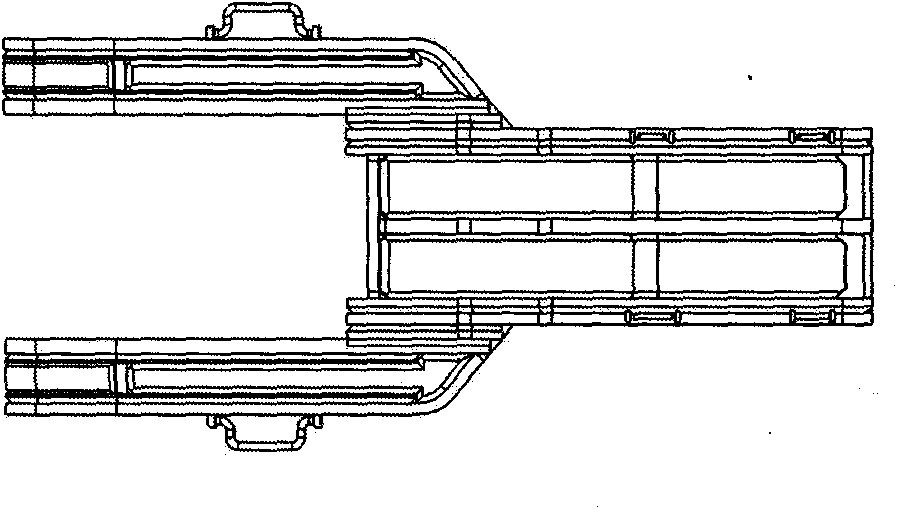

[0019] Such as figure 1 , figure 2 and image 3 As shown, in the present embodiment, including the side guard 1, the top beam 3, the column 18, the four-bar mechanism and the base 15, the base 15 is hinged with a front link 13 and a rear link 14, and the upper end of the upper link 12 is hinged On the top beam 3, the upper link 12, the front link 13, the rear link 14 and the base 15 are hinged to each other to form a four-bar linkage mechanism. The upper link 12, the front link 13 and the rear link 14 are all made of high-strength box Body welding structure, in which the upper link 12 is Y-shaped and has a skylight. Goaf filling situation; the hydraulic support is also provided with a rear top beam 7 and a rear base 23, the front end of the rear top beam 7, the rear end of the top beam 3 and the upper end of the upper connecting rod 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com