Planeness detecting device for surface-mounted welding plates of electron components

A technology for flatness detection and electronic components, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low reliability, missed detection, slow manual detection speed, etc., achieve high reliability, save manpower and material resources , fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

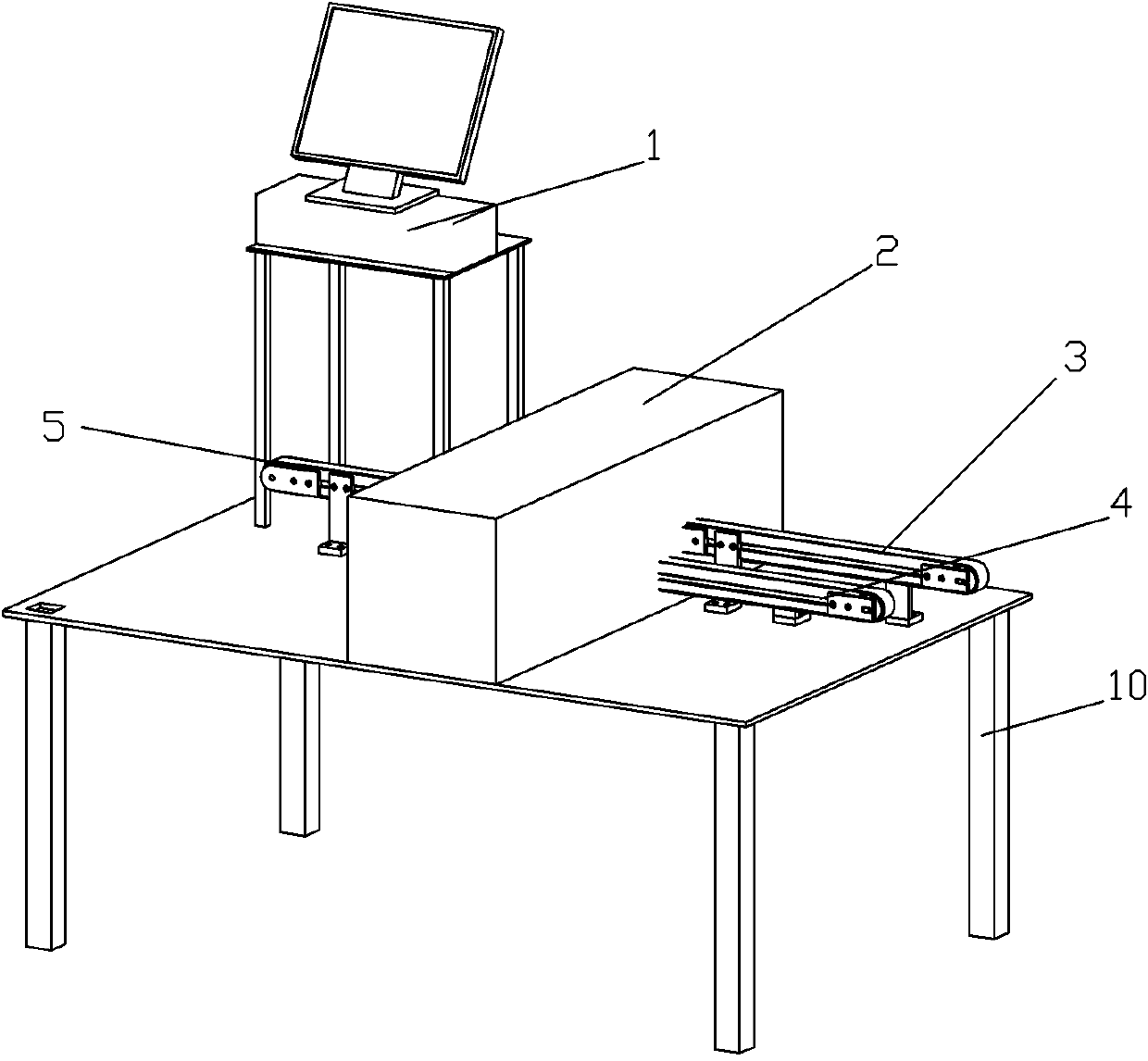

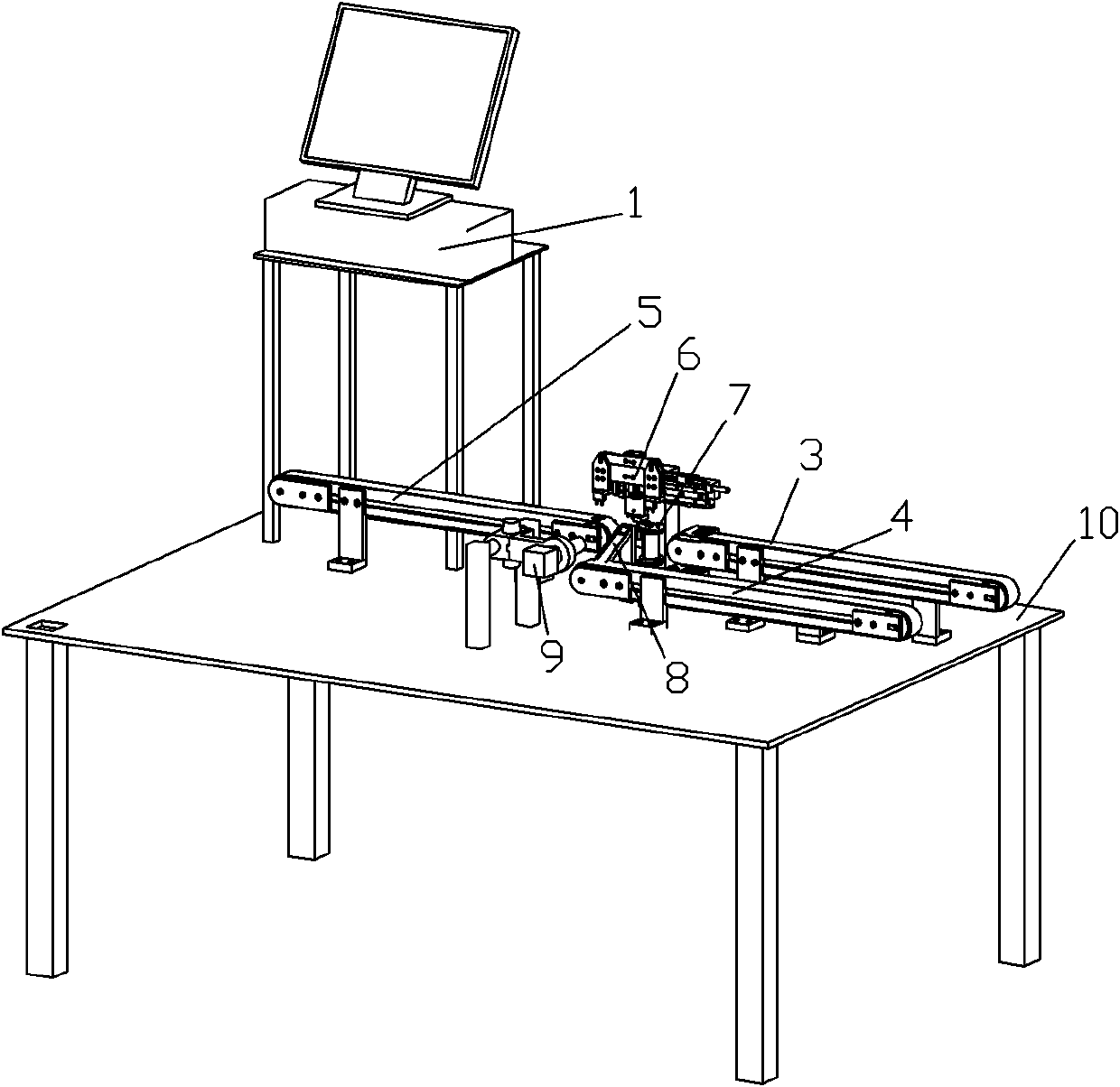

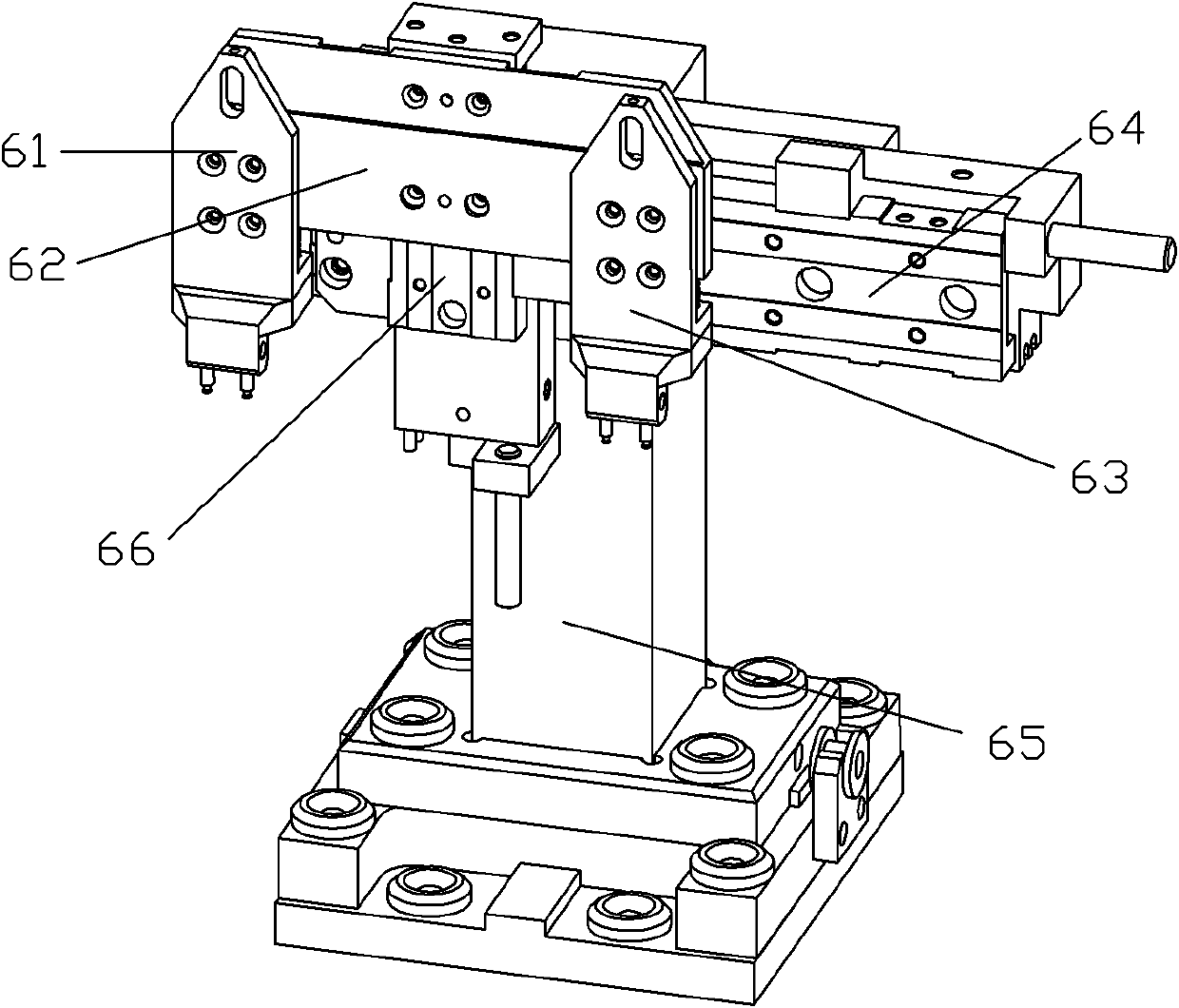

[0018] Figure 1~Figure 7 Including industrial computer 1, black box 2, feeding conveyor belt 3, unloading defective product conveyor belt 4, unloading good product conveyor belt 5, manipulator 6, first suction hand 61, suction hand connecting plate 62, second suction hand Hand 63, horizontal cylinder 64, mounting bracket 65, longitudinal cylinder 66, rotating platform 7, rotating cylinder 71, connection seat 72, light source seat 73, light source hole 731, platform 74, light transmission hole 741, groove 742, the product under test 75. Welding pad 751, guide groove for unloading defective products 8, vision system 9, video microscope objective lens 91, objective lens fixing bracket 92, focusing knob 93, focusing horizontal moving platform 94, vision system fixing bracket 95, rack 10, etc. .

[0019] Such as figure 1 , figure 2 As shown, the present invention is a flatness detection device for surface mount pads of electronic components. A dark box 2 is fixed on the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com