Quasi-distributed optical fiber temperature and stress sensor and detector

A technology of stress sensor and optical fiber temperature, applied in the field of sensing, achieves the effects of high sensitivity, simple structure, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

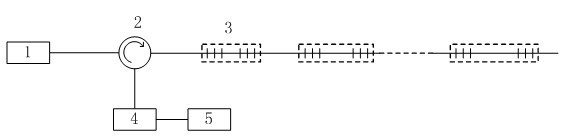

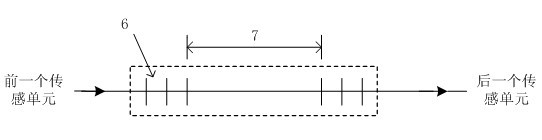

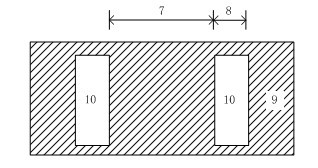

[0022] When writing gratings on single-mode fiber, the figure 2 The metal baffle shown, such as an aluminum sheet, is placed in front of the phase mask to obtain an F-P cavity with the desired cavity length; because the gate length is fixed, by adjusting the scanning speed of the ultraviolet laser, a suitable FBG reflection can be obtained Rate. Using this method, a series of F-P interferometers with different cavity lengths can be written on the same single-mode optical fiber by changing the distance between the two light-transmitting holes of the baffle.

[0023] When working, the sensing fiber is buried in the area where temperature and stress need to be monitored, and the light emitted by the spectral light source passes through the circulator to each F-P cavity on the sensing fiber and is reflected back to the circulator to reach the spectrum analyzer. The reflected light spectrum information detected by the spectrum analyzer is sent to the computer for processing. Per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com