Composite film panel

A composite film and panel technology, which is applied in the field of button panels, can solve problems such as poor quality stability, insufficient transparency, and complicated manufacturing processes, and achieve the effects of convenient and diverse combinations, good flexibility, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Select the above-mentioned TPU film printed with the key character pattern 2 as the uppermost polymer film 1, and the PC film printed with the key trademark graphic pattern 4 as the lowermost polymer film 5, and use polyurethane glue to bond the two layers of polymer film. The films are bonded together to form a composite film with a total thickness of 0.1 mm. Then according to the specification requirements of the button, it is cut into composite membrane panels of corresponding size.

Embodiment 2

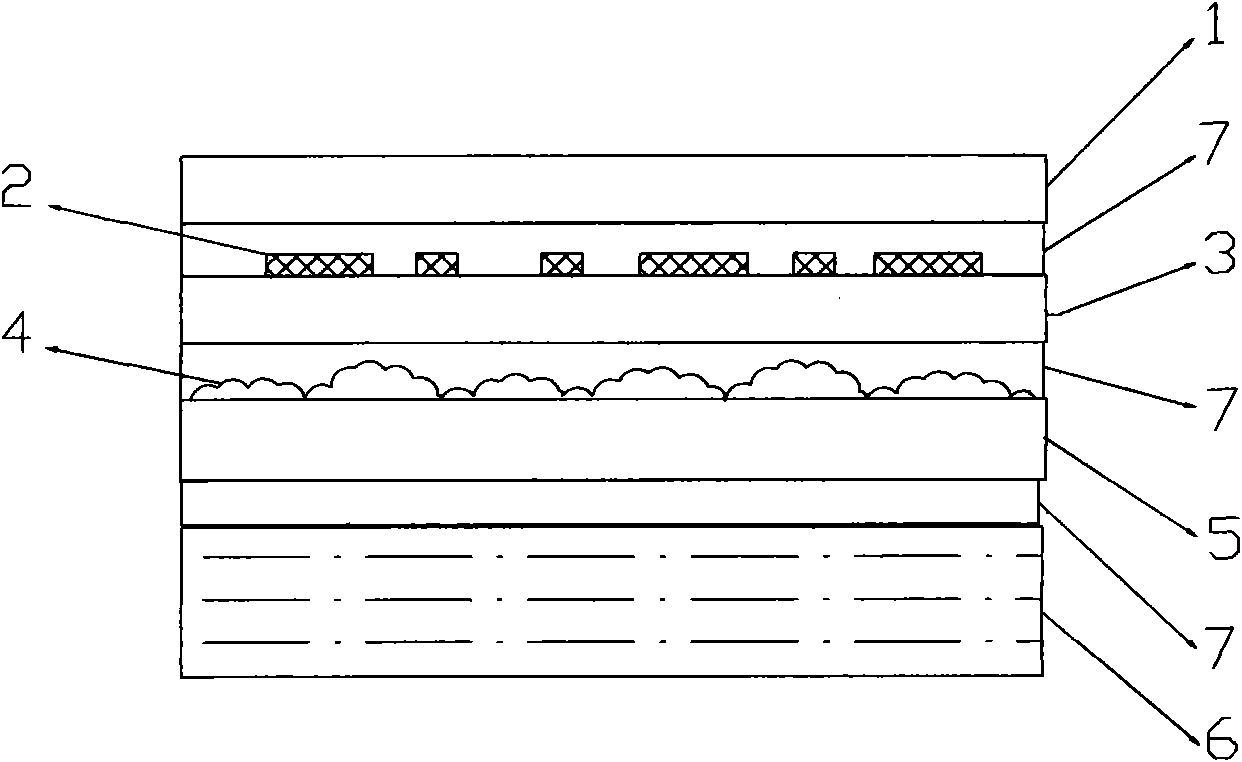

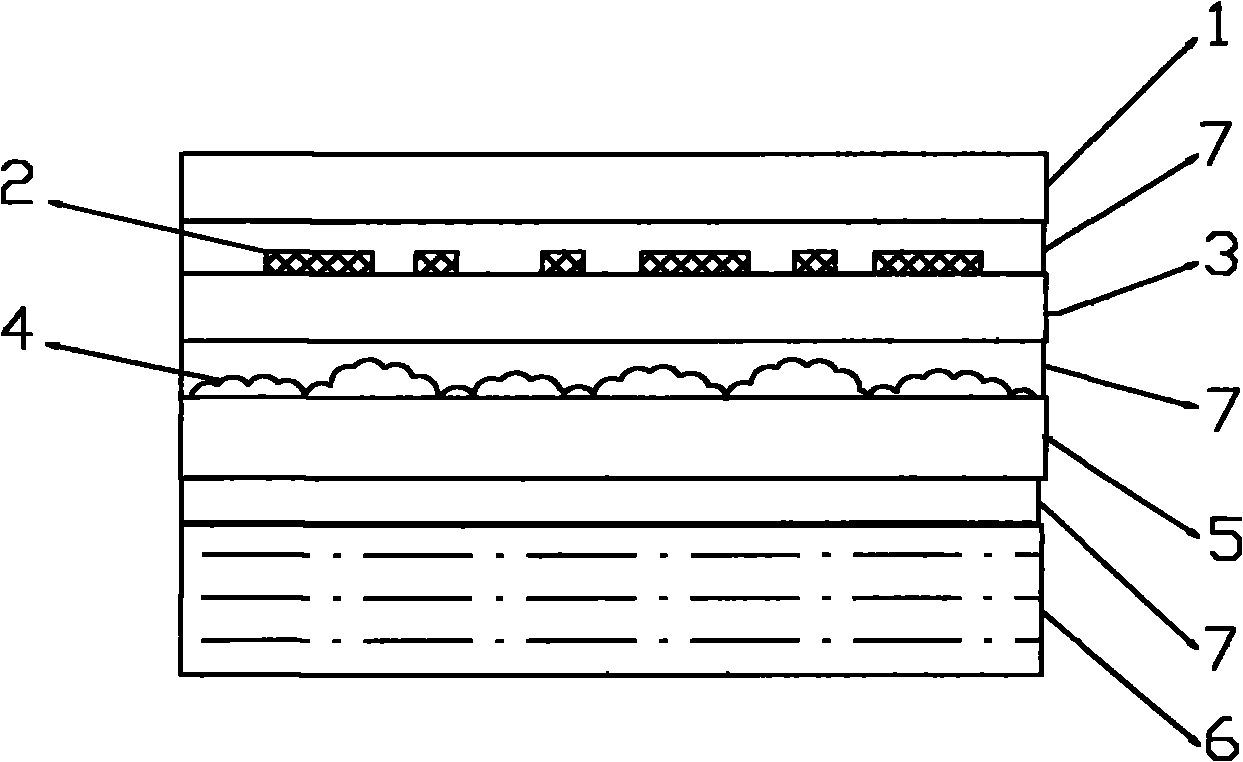

[0022] Embodiment 2: as shown in the accompanying drawing, select the above-mentioned PET film that is not printed with any pattern for use as the uppermost polymer film 1, and the PP film with the button character pattern 2 printed with a three-dimensional display effect is used as the middle layer polymer film 3, The PET film printed with the button trademark graphic pattern 4 is used as the lowermost polymer film 5, and the thickness of the lowermost polymer film 5 is greater than that of other layers. The three layers of polymer films are bonded together with epoxy glue to form a composite film with a total thickness of 1.5 mm, and the light guide plate 6 is bonded to the bottom of the polymer film at the bottom. Then according to the specification requirements of the buttons, it is cut into composite film panels for supporting the buttons.

Embodiment 3

[0023] Embodiment 3: as shown in the accompanying drawing, select the above-mentioned PVC film that does not have any pattern to be printed as the uppermost polymer film 1, the PET film of the button character pattern 2 is used as the middle layer polymer film 3, and the button trademark graphic pattern is printed 4 and the PMMA film with graphic patterns of shading effect is used as the bottom polymer film 5, and other polymer films printed with patterns can also be selected for use to do other more layers. Three or more layers of polymer films are bonded together by UV light-curing polyurethane glue to form a composite film with a total thickness of 3mm. The lowermost polymer film is bonded with a luminescent sheet 6 below. Then according to the specification requirements of the buttons, it is cut into composite film panels for supporting the buttons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com