Ink cleaning liquid

A technology of washing liquid and surfactant, applied in the field of washing liquid for ink, can solve problems such as nozzle clogging, and achieve the effects of inhibiting aggregation, excellent washing ability, and not easy to corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] As the cleaning liquid for ink of Example 1 (hereinafter, described as "washing liquid A for ink" according to the case.), prepare and add acetylenic diol (manufactured by Air Products and Chemicals. Inc., trade name: Surfynol 104DPM) Ethylene glycol monobutyl ether acetate. The content of acetylenic diol in the ink washing liquid A was 1.0% by mass relative to the total mass of the ink washing liquid.

[0059] 2 g of ink cleaning solution A and 40 g of ion-exchanged water were stirred for 5 minutes with a stirrer to obtain mixed solution A1.

[0060] After the mixed liquid A1 was filtered with a filter, the pH of the mixed liquid A1 was measured with a pH meter. The results are shown in Table 1.

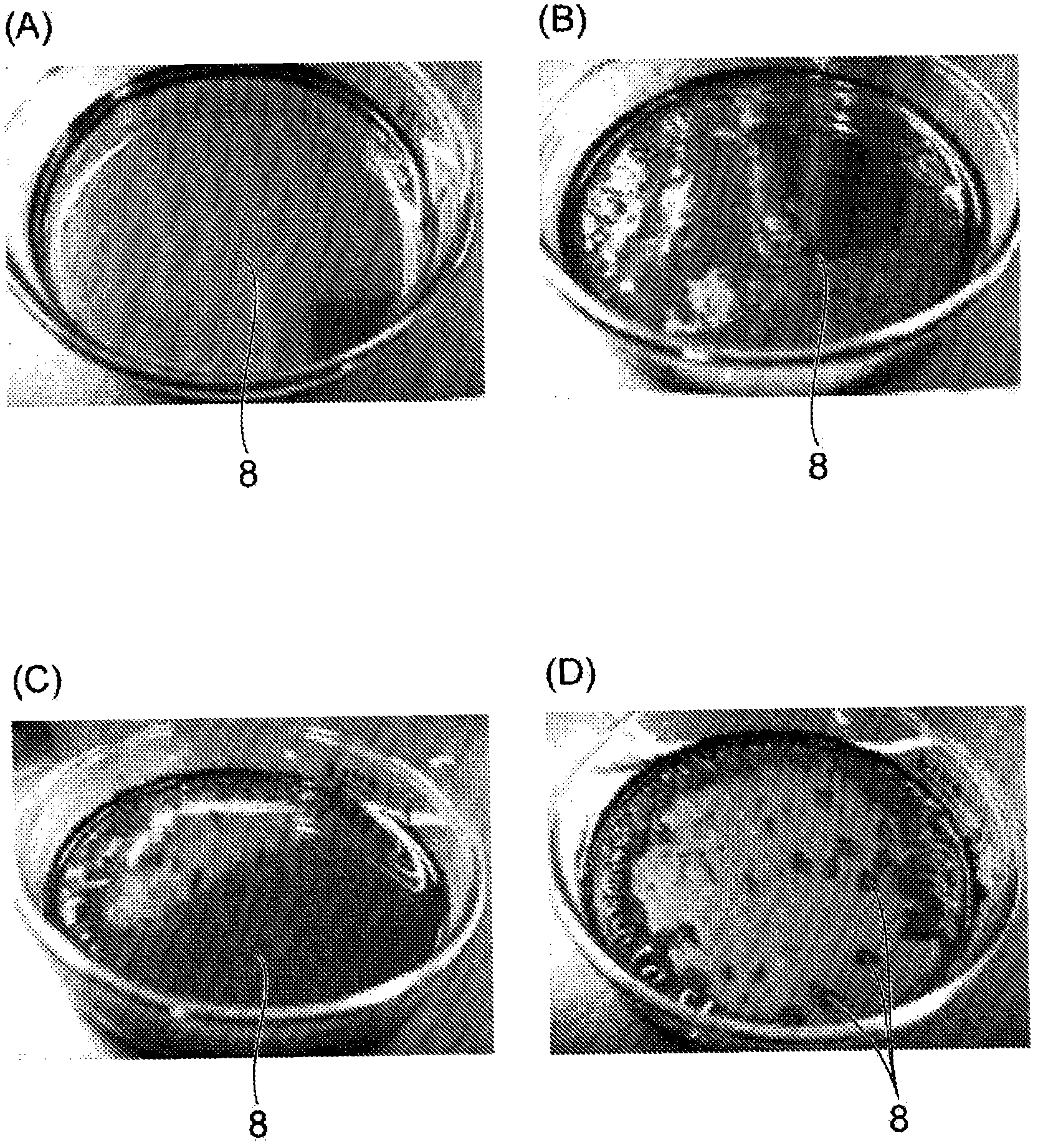

[0061] Next, thermally accelerated deterioration treatment is performed on the filtered mixed liquid A1. In the heat-accelerated deterioration treatment, the mixed liquid A1 was kept for 12 days in an environment with a temperature of 60° C. and a humidity of 45%. This he...

Embodiment 2a

[0073] Prepare a BS ink containing a pigment, ethylene glycol monobutyl ether acetate as a main solvent, and a dispersant. The BS ink was mixed with the ink washing liquid A to prepare a mixed liquid A2. The mass ratio of the BS ink contained in the mixed liquid A2 to the ink washing liquid A was 1:9.

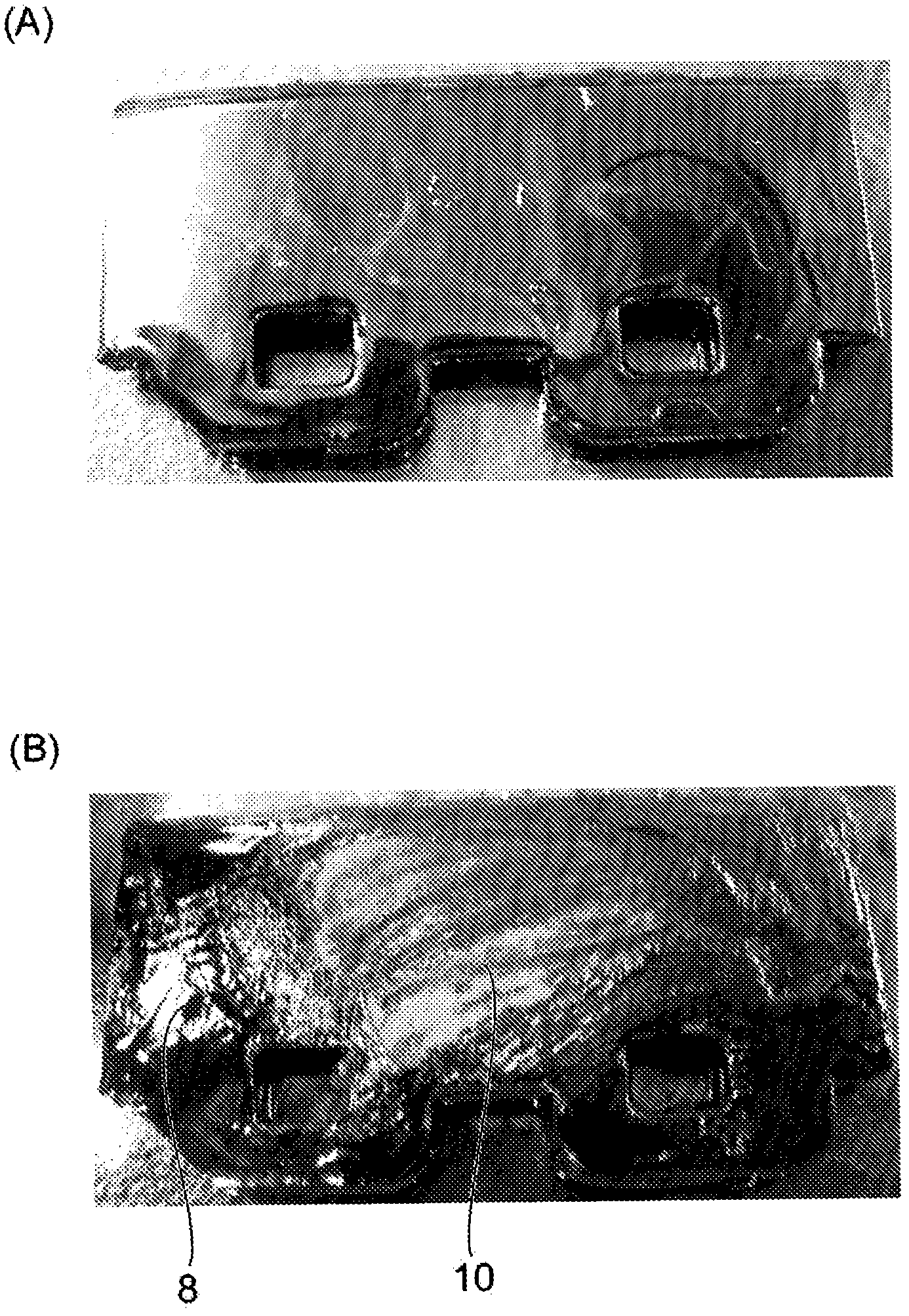

[0074] The average volume particle size MV, the average number average particle size MN, the average area particle size MA of the particle group contained in the mixed solution A2, and the accumulation time from the small particle size side in the particle size distribution based on the volume of the particle group are respectively measured. Particle diameter D50 at which the cumulative rate is 50%. The measurement results are shown in Table 2. A particle size analyzer (MICROTRAC UPA-EX150) manufactured by Nikkiso Co., Ltd. was used for the measurement of each particle diameter.

[0075] Next, in the same manner as in Example 1, the thermally accelerated degradation treatmen...

Embodiment 2b

[0083] Except for mixing the BS ink and the ink cleaning solution A at a mass ratio of 1:1, the MV, MN, MA, D50 and their values before and after the heat-accelerated degradation treatment were obtained for the mixed solution A2 by the same method as in Example 2a. rate of change. The results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com