Peening hammer and peening hammer component

A technology for striking a hammer and a hammer handle, which is applied in the direction of printing, etc., can solve the problems of affecting the character recognition effect, uneven striking force, incomplete characters, etc., and achieves the effect of good overall structure, excellent structure, and clear and complete printing and writing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

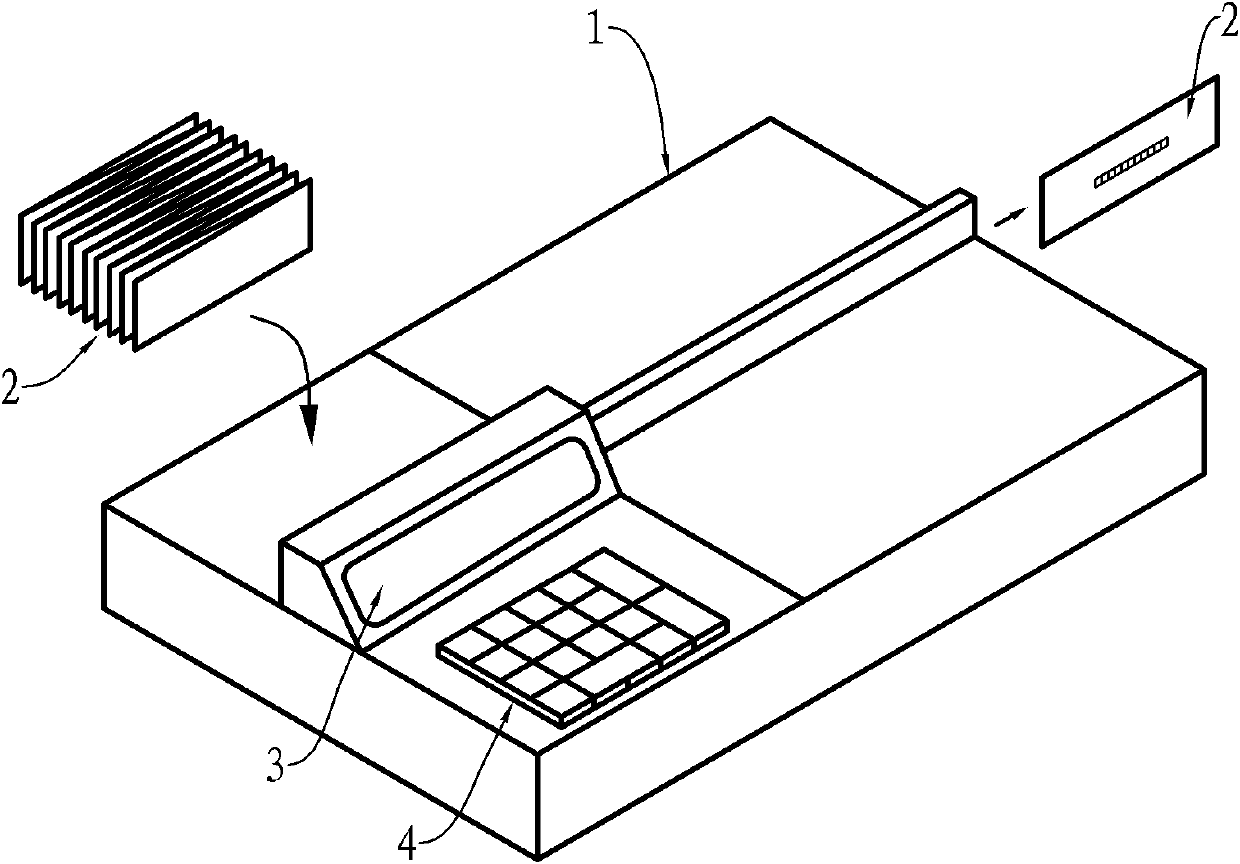

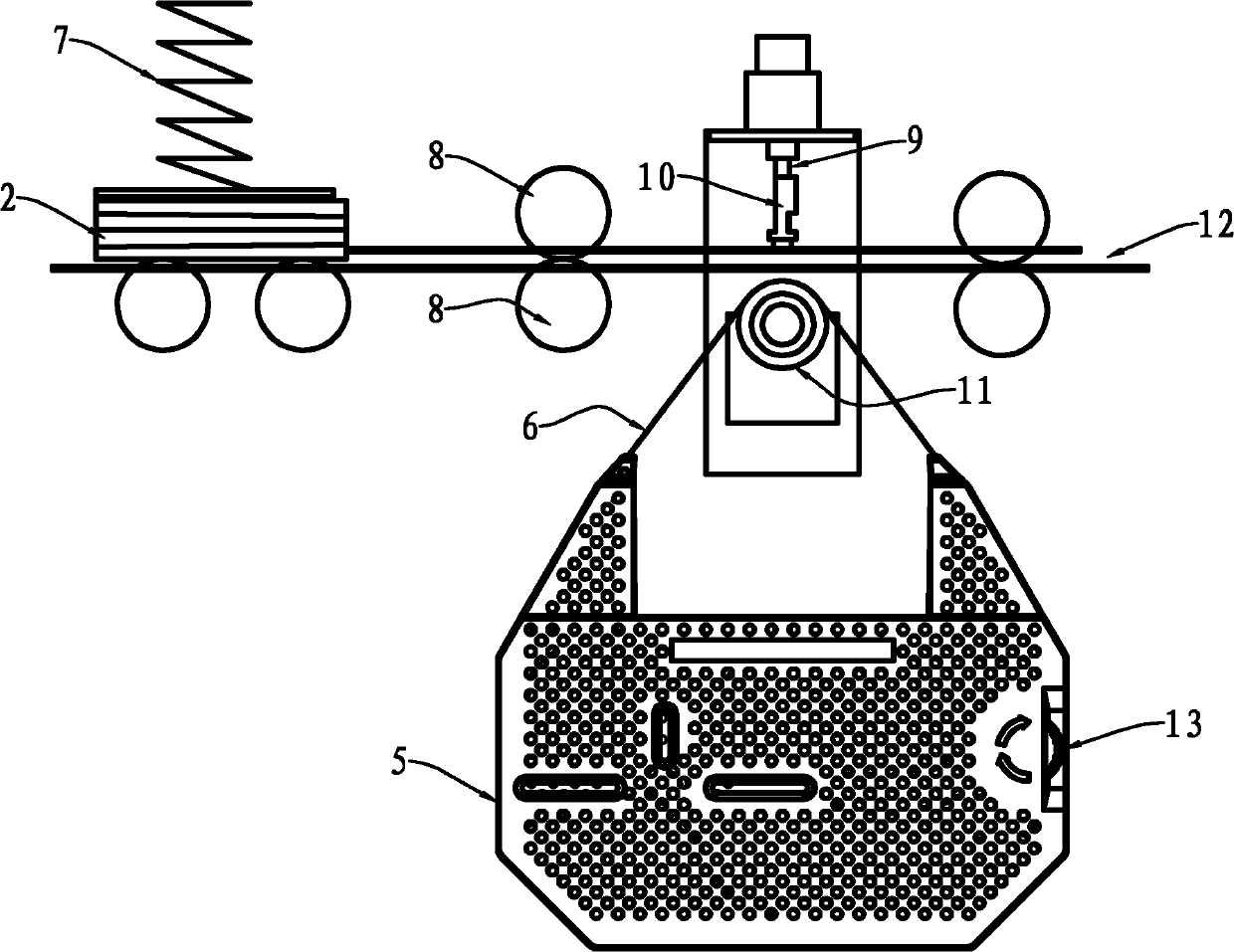

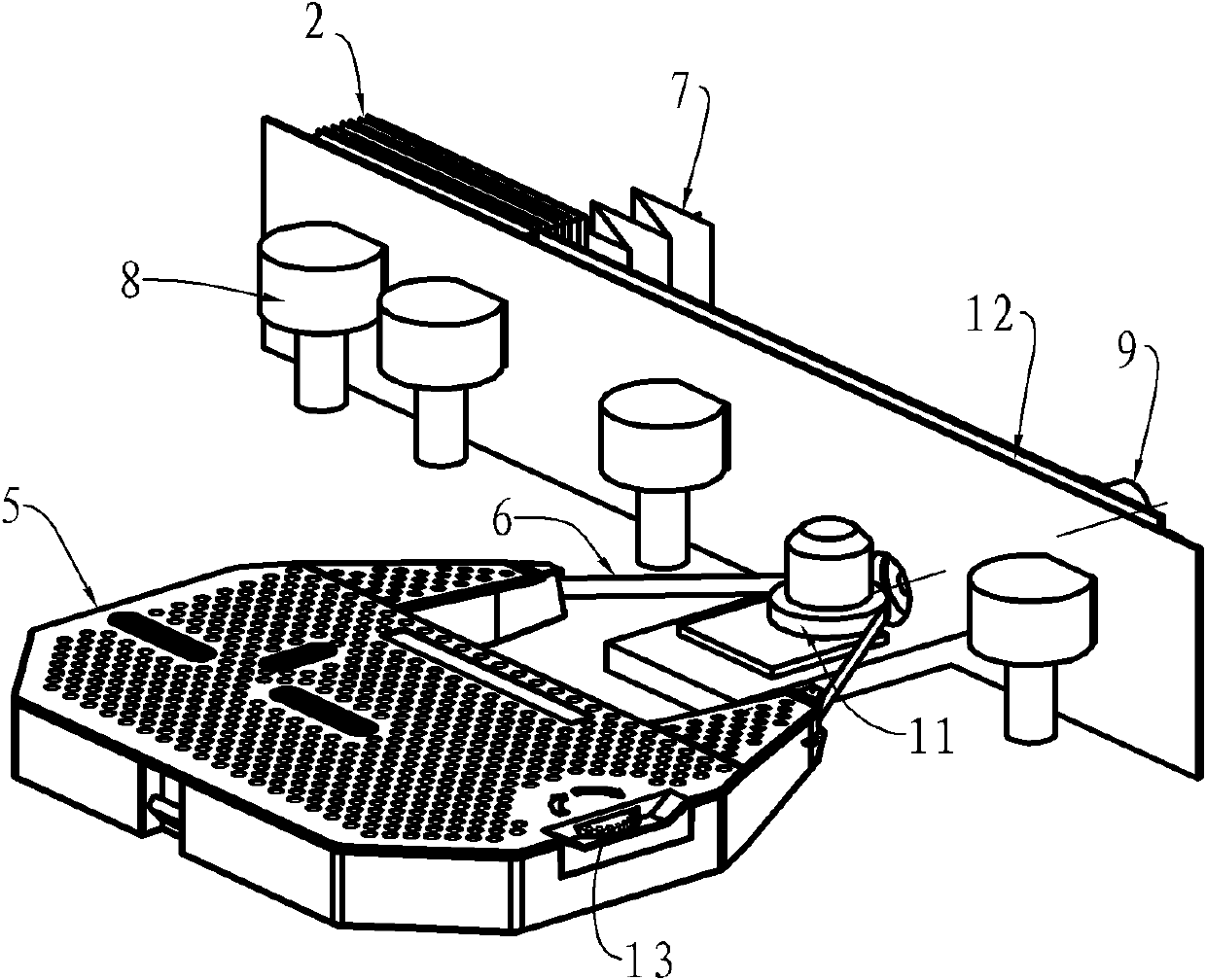

Embodiment 1

[0054] see Figure 15 , 16 And 17, a kind of percussion hammer that is used to be installed on a kind of impact printer, has a sleeve part 21 that is used to be sleeved on the drive shaft and a striking part 22 that is used to beat the dial, the sleeve part 21 and the beating part 22 are integrally formed by injection molding. The sleeve portion 21 has a cylindrical shape, preferably a cylindrical shape in this embodiment, and has an inner diameter consistent with the outer diameter of the drive shaft. And there is a notch on the circumference of the sleeve part 21 which is one-third of the circumference, so that the sleeve part 21 can be fitted onto the drive shaft from the side of the drive shaft in a direction perpendicular to the axis of the drive shaft. In addition, a notch 211 is provided on the outer peripheral surface of the thicker inner diameter section of the sleeve portion 21 to facilitate the operation of the overall manufacturing process of the hammer. The bea...

Embodiment 2

[0057] see Figure 18 , 19 , 20, 21, a hammer used to be installed on another printer has a hammer head 32 and a hammer handle 31. The hammer head 32 is a cylindrical body, which is preferably a cylindrical body in this embodiment. One circular end surface of the cylindrical body is the hitting surface 320, and the center position of the other circular end surface has a cylindrical hole along the axial direction of the cylindrical body. A cylindrical metal body 321 with the same size as the cylindrical hole is inserted into the hole. The end surface area of the cylindrical metal body 321 is larger than the effective striking area of the striking surface 320 . The hammer handle 31 is a long strip with a certain radian, one end of the hammer handle 31 is fixedly connected to the peripheral surface of the hammer head 32, and the other end of the hammer handle 31 is provided with a mounting column 33, which is used to place the hammer Installed on the positioning frame, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com