Treatment device for producing matrixes and organic manures by utilizing dairy cow excrements

A processing device and a technology for organic manure, which are applied in the field of processing devices for human or animal excrement, can solve the problems of waste of cow dung, mixed components, large processing capacity, etc., and achieve the effect of increasing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

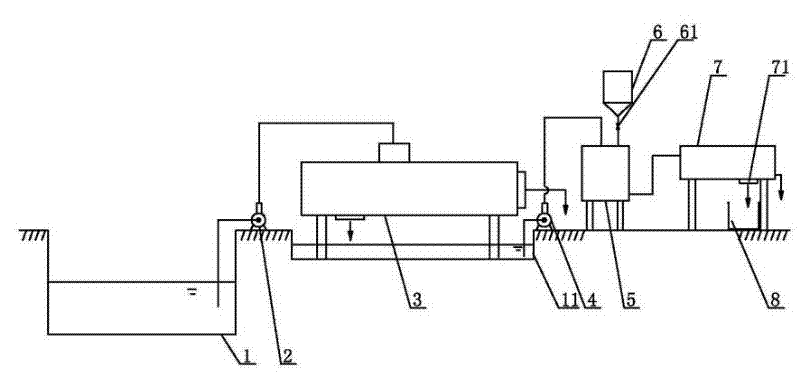

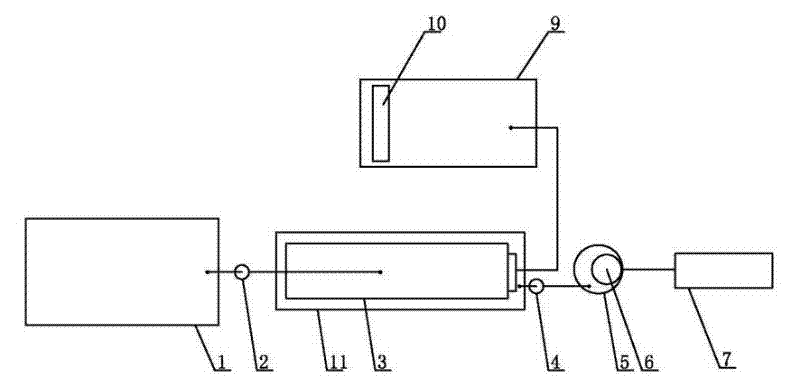

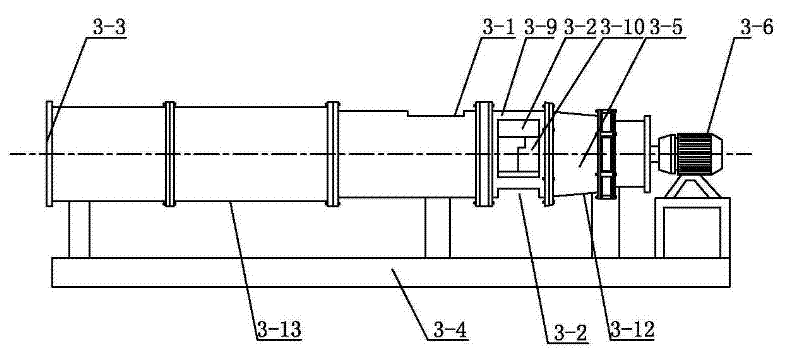

[0032] Such as figure 1 The shown processing device for producing matrix and organic manure with dairy cow manure, the device comprises a cow dung tank 1, a 0.5mm screw-type solid-liquid separator, a belt filter press 7 and a fermenter 9 with a sieve aperture. The septic tank 1 is connected to the screw type solid-liquid separator 3 by pipelines, the thick slurry pump 2 is provided between the cow dung tank 1 and the screw type solid-liquid separator 3, and the screw type solid-liquid separator 3 is connected to the fermentation tank 9 by pipelines , the fermenter 9 is provided with a turner 10 (see figure 2 ). The bottom of the spiral solid-liquid separator 3 is provided with a liquid phase collection tank 11, and the spiral solid-liquid separator 3 is erected above the liquid phase collection tank 11 through the bracket 3-4, and the liquid phase collection tank 11 is connected with the pump 4, and the pump The outlet end of 4 is connected with a mixing tank 5, and a flocc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com