Phospholipases, nucleic acids encoding them and methods for making and using them

A phospholipase, nucleic acid technology, applied in the fields of botanical equipment and methods, biochemical equipment and methods, fat oil/fat refining, etc., can solve problems such as yield loss and quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

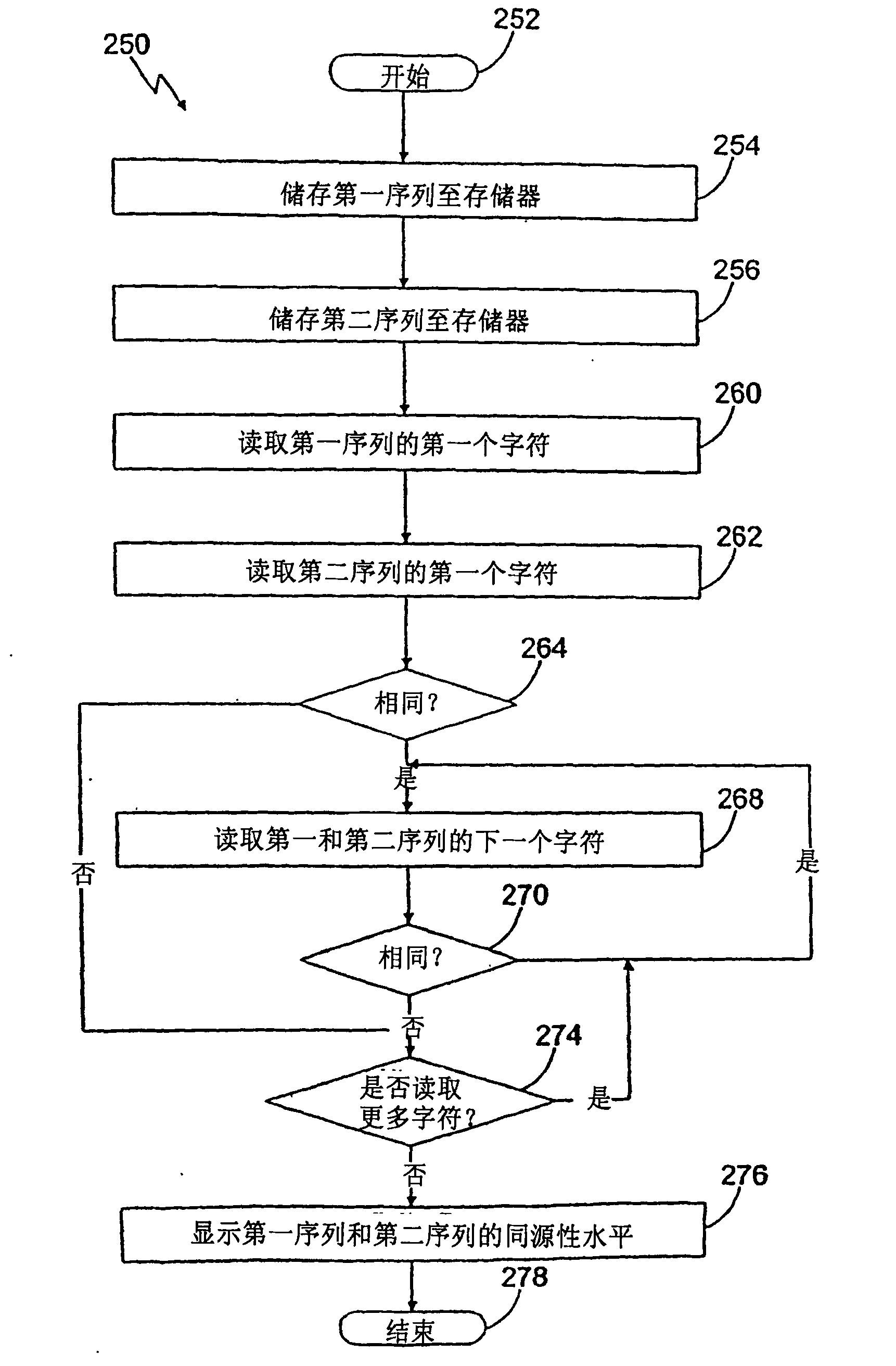

[0517] Example 1: BLAST program for sequence identity exploration

[0518] This example illustrates a typical sequence identity program used to determine whether a nucleic acid is within the scope of the invention. The NCBI BLAST 2.2.2 program was applied, with to blastp selected by default. In addition to the default filtering setting, all default values apply (ie, all parameters are set to default except filtering is set to OFF); where the "FF" setting is applied, it disables filtering. Due to the short length of the sequences, applying default filtering often leads to Karlin-Altschul violations. Default values used in this example:

[0519]

[0520] Other default settings are: low complexity filtering off, for protein word length 3, BLOSUM62 matrix, gap presence penalty -11 and gap extension penalty -1. The "-W" option is set to the default value of 0. This means that, if not set, the word length defaults to 3 for proteins and 11 for nucleotides. Settings are ...

Embodiment 2

[0525] Example 2: Simulation of PLC-mediated degumming

[0526] This example illustrates the simulation of phospholipase C (PLC) mediated degumming.

[0527] Due to the poor solubility of phosphatidylcholine (PC) in water, it was initially dissolved in ethanol (100 mg / ml). For initial assays, stock solutions of PC were prepared by dissolving in 50 mM morpholinopropanesulfonic acid or 60 mM citric acid / NaOH at pH 6. PC stock solution (10 μl, 1 μg / μl) was added to 500 μl refined soybean oil (with 2% water) in an Eppendorf tube. To obtain an emulsion, the contents of the tube were mixed by vortex mixer for 3 minutes (see Figure 5 A). The oil and water phases were separated by centrifugation at 13,000 rpm for 1 minute ( Figure 5 B). The reaction tube was pre-incubated at the desired temperature (37°C, 50°C, or 60°C), and 3 μl of PLC (0.9 U / μl) from Bacillus cereus was added to the aqueous phase ( Figure 5 C). Disappearance of PC was analyzed by TLC using chloroform / met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com