Solid-phase reaction preparation method for silicious manganese thermoelectric material

A technology of solid phase reaction and thermoelectric materials, applied in the manufacture/processing of thermoelectric devices, etc., can solve the problems that limit the practical application of high manganese silicon thermoelectric materials, and achieve the effect of low price, low requirements for equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

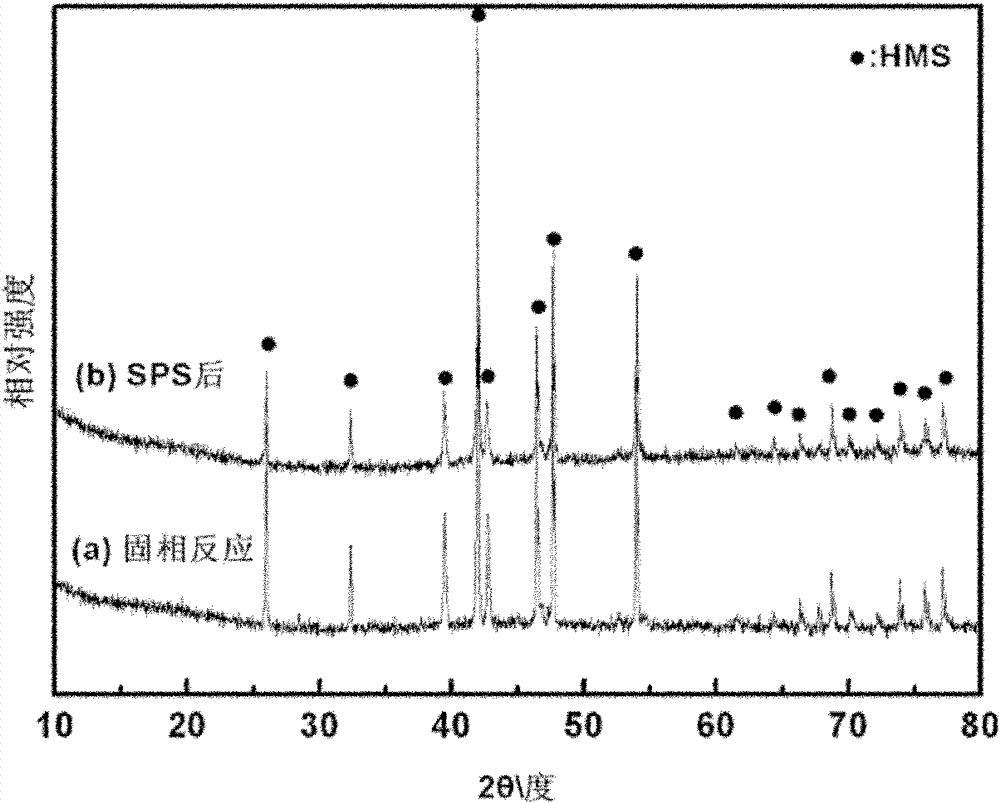

Embodiment 1

[0031] A solid phase reaction preparation method for high manganese silicon thermoelectric material, it comprises the following steps:

[0032] 1) Using Mn powder and Si powder as raw materials, according to MnSi 1.80 Stoichiometric proportioning (i.e. weigh Si powder and Mn powder according to the molar ratio of Si powder and Mn powder is 1.80:1), weigh the total amount to 2.5g, and mix the raw material powders by hand in a mortar to obtain a mixed uniform powder;

[0033] 2) Press the uniformly mixed powder into a block on a tablet press (the block is a cylindrical block with a diameter of 15mm, and the pressure of the tablet press is 20-30MPa), and place the block in a quartz glass tube (inner diameter 17mm, outer diameter 20mm), vacuumize and seal, then place in a muffle furnace for solid phase reaction at 900°C for 12h (during the solid phase reaction, the temperature is raised from 300°C to 900°C at a heating rate of 10°C / min , and then kept at 900°C for 12h), and cool...

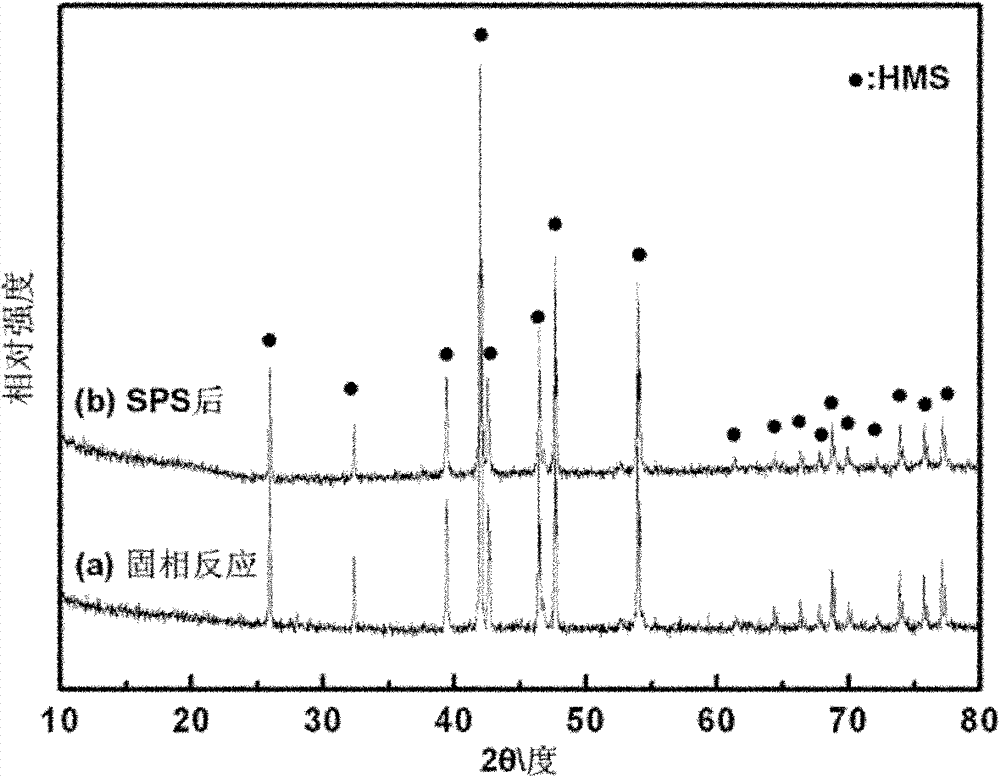

Embodiment 2

[0039] A solid phase reaction preparation method for high manganese silicon thermoelectric material, it comprises the following steps:

[0040] 1) Using Mn powder, Si powder and Ge powder as raw materials, according to Mn(Ge 0.016 Si 0.984 ) 1.80 Stoichiometric ratio ingredients (Si is missing during the reaction process, if the nominal ratio is MnSi 1.80 , the actual ratio obtained is MnSi 1.75 . Here Ge replaces the Si position, the sum of the molar weights of Ge and Si is 1), the total weight is 2.5g, and the raw material powder is manually mixed in a mortar to obtain a uniformly mixed powder;

[0041]2) Press the uniformly mixed powder into a block on a tablet press (the block is a cylindrical block with a diameter of 15mm, and the pressure of the tablet press is 20-30MPa), and place the block in a quartz glass tube (inner diameter 17mm, outer diameter 20mm), vacuumize and seal, then place in a muffle furnace for solid phase reaction at 900°C for 12h (during the solid...

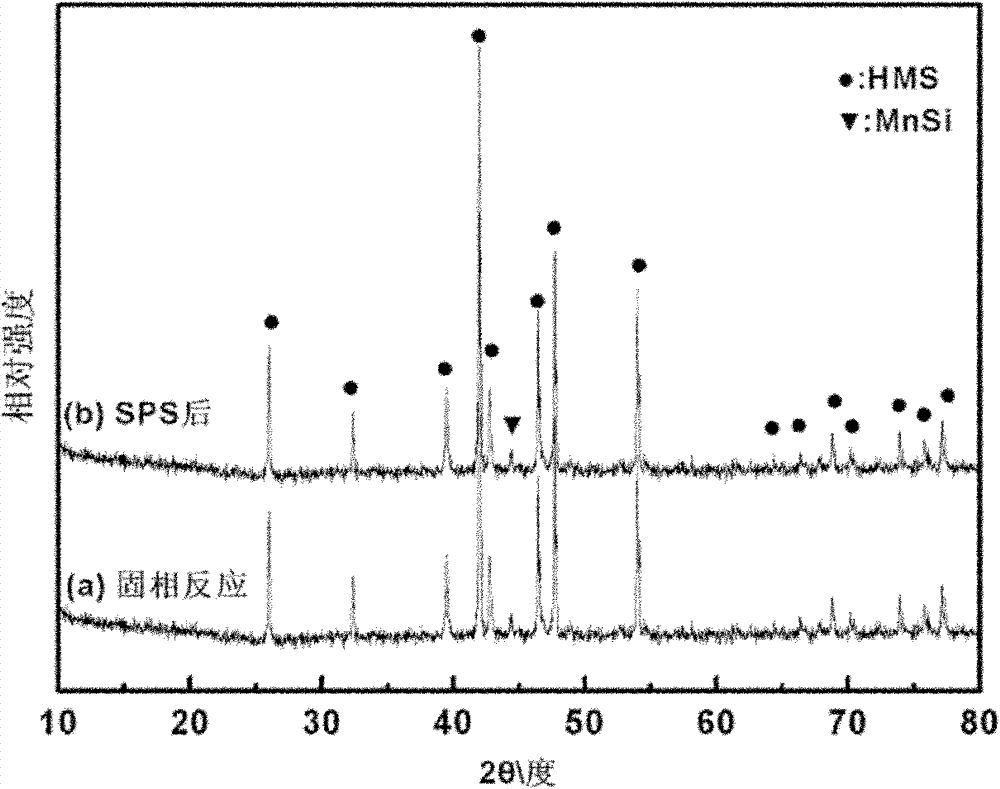

Embodiment 3

[0047] A solid phase reaction preparation method for high manganese silicon thermoelectric material, it comprises the following steps:

[0048] 1) Using Mn powder and Si powder as raw materials, according to MnSi 1.75 Stoichiometric proportioning (i.e. weighing Si powder and Mn powder according to the molar ratio of Si powder and Mn powder is 1.75:1), weighing a total of 2.5g, mixing the raw material powders by hand in a mortar to obtain a mixed uniform powder;

[0049] 2) Press the uniformly mixed powder into a block on a tablet press (the block is a cylindrical block with a diameter of 15mm, and the pressure of the tablet press is 20-30MPa), and place the block in a quartz glass tube (inner diameter 17mm, outer diameter 20mm), vacuumize and seal, then place in a muffle furnace for solid phase reaction at 900°C for 12h (during the solid phase reaction, the temperature is raised from 300°C to 900°C at a heating rate of 10°C / min , and then kept at 900°C for 12h), and cooled w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com