Torsional vibration damper for shafting system

A technology of shafting torsional vibration and shock absorber, which is applied in spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problems of small number of effective coils of straight spring, limited maximum transmission torque, and high processing and manufacturing cost. Achieve the effect of small curvature, high dynamic strength and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

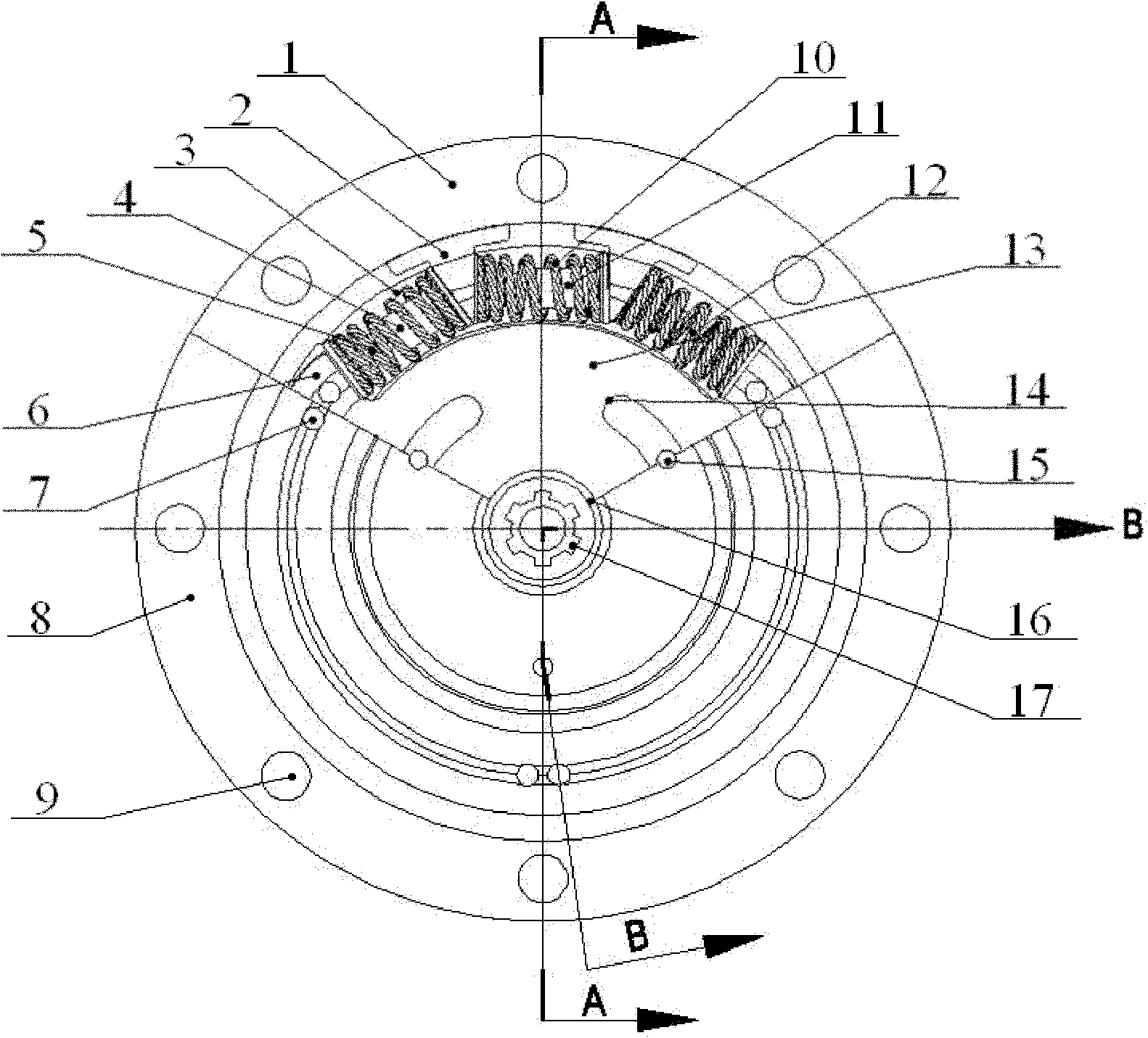

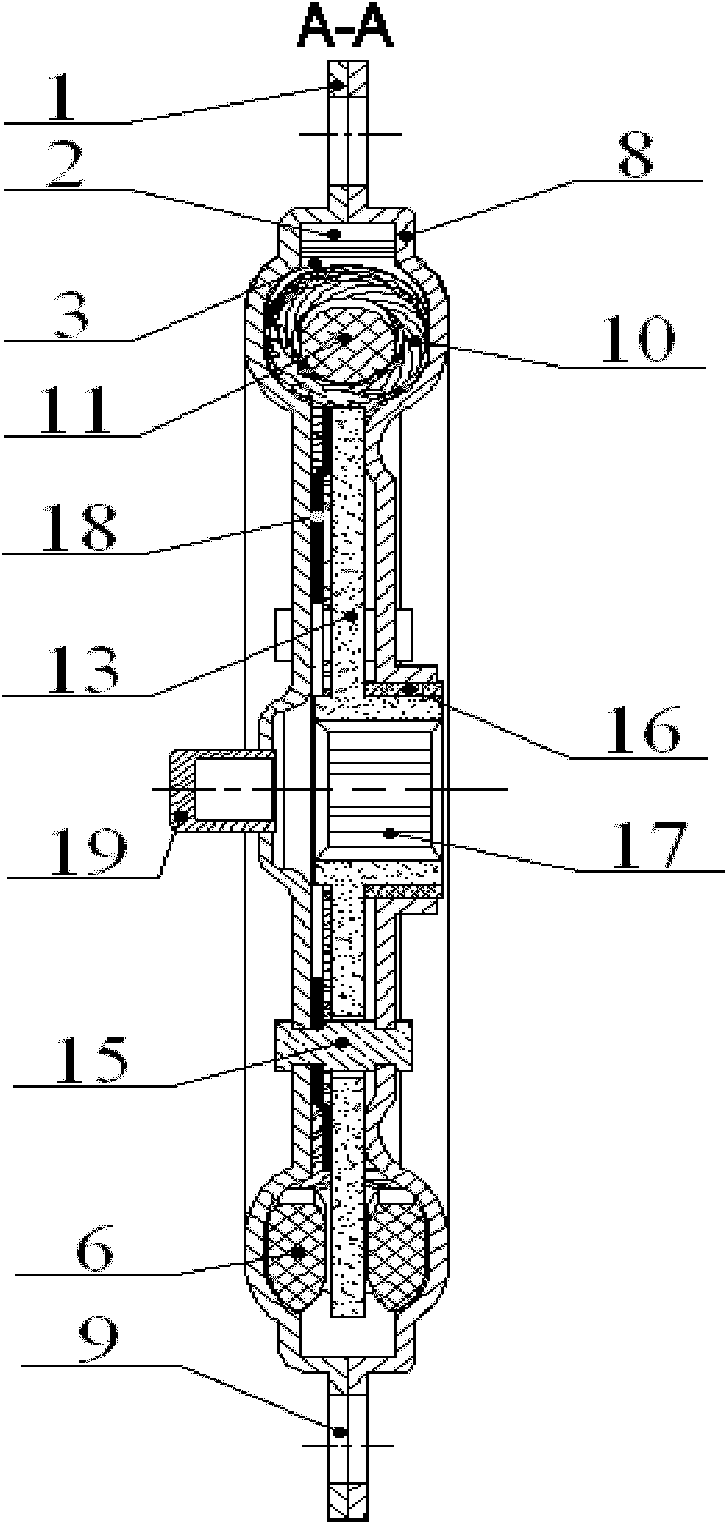

[0030] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

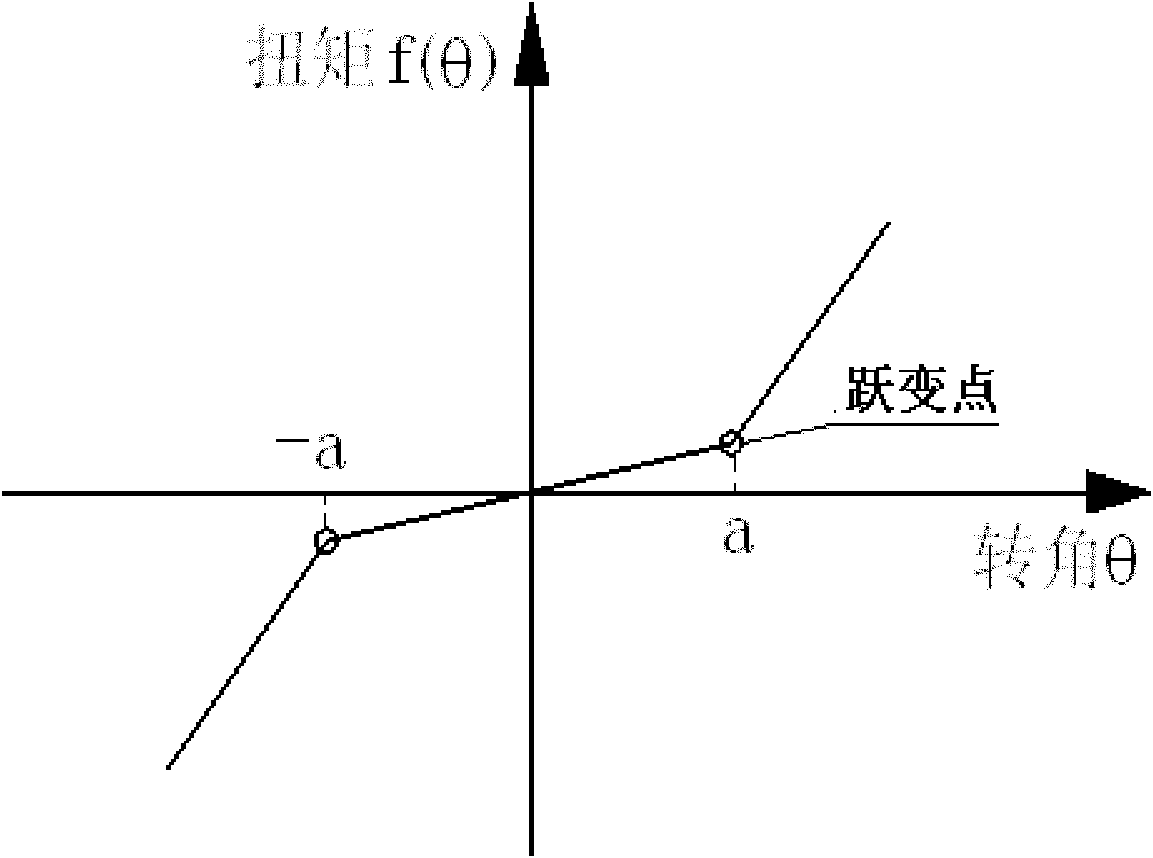

[0031] During specific implementation, the structure of the present invention is as follows Figure 2 to Figure 9 As shown, a shafting torsional vibration damper includes a driving end, a driven end and an elastic mechanism, and the driving end includes a shell one 1 and a shell two 8 that are coupled and connected into a hollow disk; the slave The driven end includes a driven disc 13 coaxially arranged in the cavity of the housing one 1 and the housing two 8; the driving end is rotatably supported on the driven end by a sliding bearing 16; The connecting hole of the driving system is provided with matching openings corresponding to the connecting holes of the driven system on the driving end; there is an annular spring chamber 3 for installing the elastic mechanism between the outside of the driven disk 13 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com