Silica-based unequal-width microchannel flat heat pipe and manufacture method thereof

A flat-plate heat pipe and micro-channel technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of limiting the heat transfer performance of micro-plate heat pipes, so as to facilitate liquid reflux, enhance heat transfer capacity, and improve capillary extreme effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

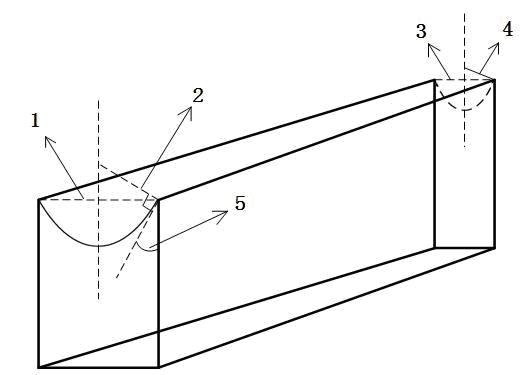

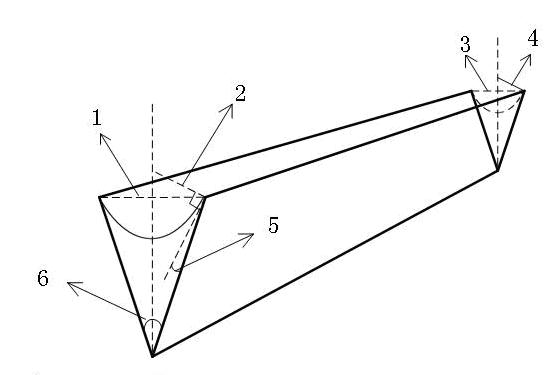

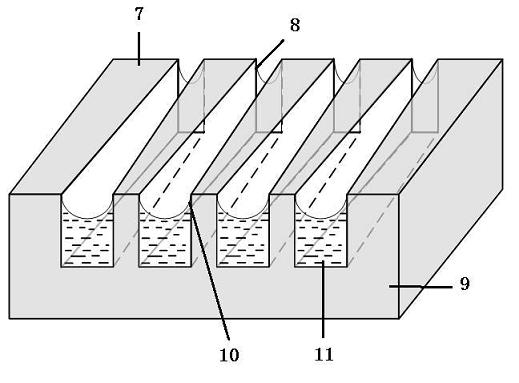

[0034] The silicon-based unequal-width micro-channel flat micro-heat pipe of the present invention utilizes the principle that the liquid generates non-mechanical dynamic flow in the micro-channel under the action of surface tension, and etches a cluster of structures with the same width on two silicon substrates respectively. Continuously changing unequal width rectangular or V-shaped microchannels (such as figure 1 , figure 2 As shown), in the case of a small liquid filling rate, the working fluid generates a capillary pressure difference at both ends of the channel through the liquid surface tension to realize the flow from the wide end to the narrow end. It is characterized in that: a micro-channel structure with gradually changing width is adopted in the flat heat pipe, so that the internal pressure of the working fluid is distributed in a grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com