Spraying process of aluminum electrodes of pressure-sensitive resistant discs

A varistor, aluminum electrode technology, applied in the direction of varistor, overvoltage protection resistor, and resistors with lead-out terminals, etc., can solve problems such as product scrap, improve energy absorption, solve the phenomenon of aluminum electrode partial aluminum, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

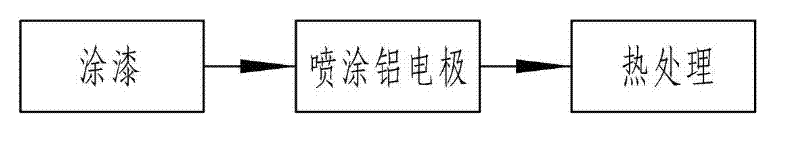

[0010] The varistor sheet aluminum electrode spraying process of the present invention is sprayed according to the following steps:

[0011] 1. Paint: Arrange the piezoresistors neatly, place them on the coating machine, coat with a layer of insulating varnish, and heat-cure in an oven at 180-220°C / 2h;

[0012] 2. Spraying aluminum electrodes: put the piezoresistors coated with insulating paint and heat-cured directly on the aluminum spraying machine to directly spray aluminum electrodes;

[0013] 3. Heat treatment: Put the varistor sheet sprayed with aluminum electrodes into the kiln, conduct heat treatment at 450-500°C, and bake off the insulating varnish around the varistor sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com