Reconfigurable microwave receiver front-end based on micro-electro-mechanical microwave power sensor

A microwave receiver and micro-electronic machinery technology, applied in electrical components, transmission systems, etc., can solve the problems of limited linear dynamic range, complex realization, large loss, etc., to protect the low-noise amplifier, keep the output stable, and avoid overload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

[0018] The specific implementation scheme of the reconfigurable microwave receiver front-end based on MEMS microwave power sensor of the present invention is as follows:

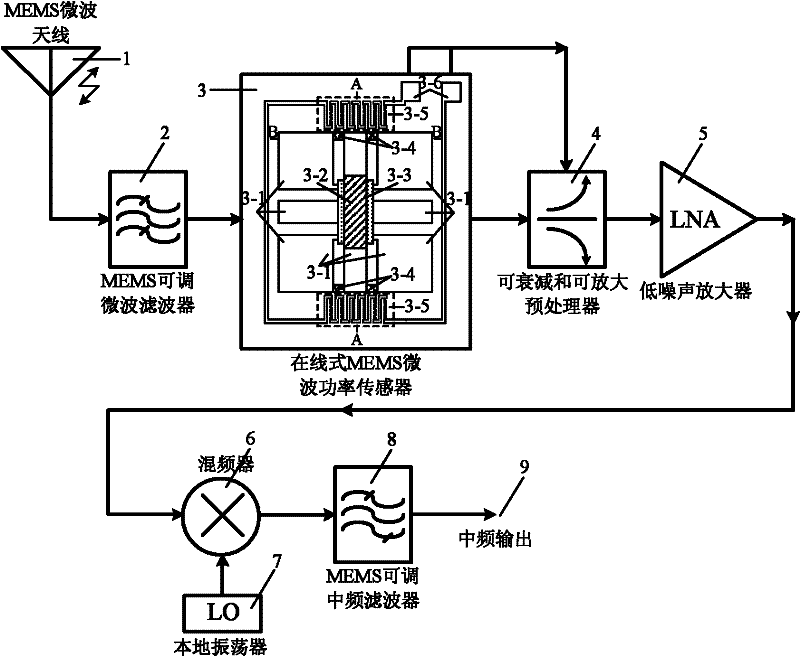

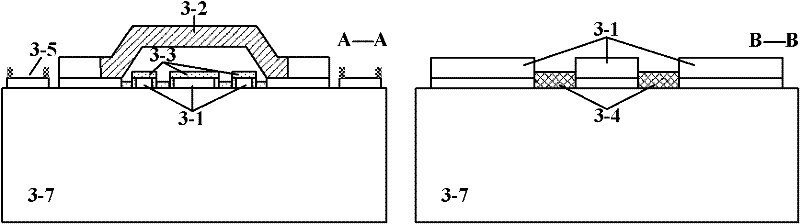

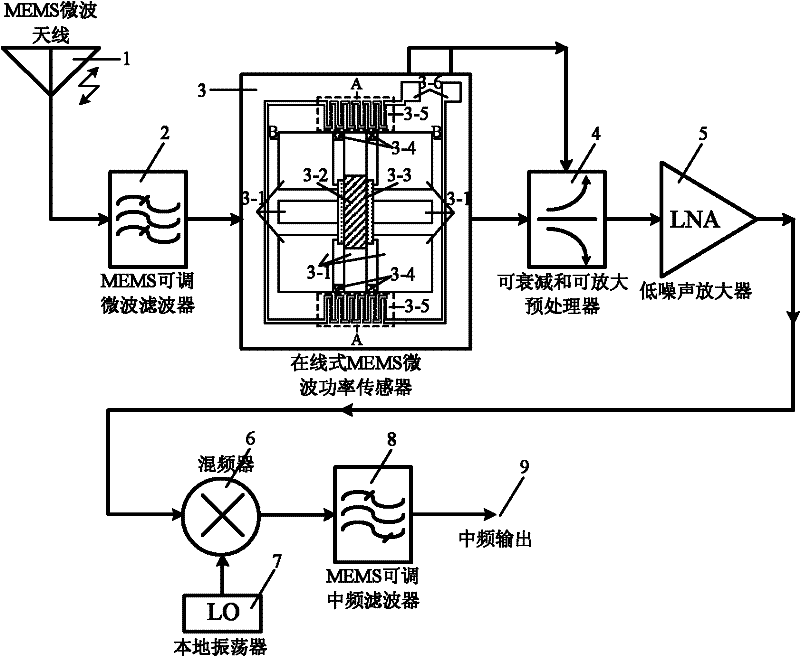

[0019] The reconfigurable microwave receiver front-end based on MEMS microwave power sensor includes 8 modules: MEMS microwave antenna 1, MEMS tunable microwave filter 2, online MEMS microwave power sensor 3, attenuation and amplification preprocessor 4 , low noise amplifier 5, mixer 6, local oscillator 7 and MEMS adjustable intermediate frequency filter 8. When the MEMS microwave antenna 1 receives the microwave signal, the microwave signal is frequency-selected by the MEMS tunable microwave filter 2, and then through the self-test of the online MEMS microwave power sensor 3, the online control can attenuate and amplify the preprocessing 4, so that the output The relatively stable microwave signal flows through the fixed-gain low-noise amplifier 5, and then the amplifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com