Mould paint spraying device

A technology of spraying device and mold coating, which is applied in the direction of casting molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult control of coating thickness, easy uneven coating, high labor intensity, etc., to prevent impact and The effect of polluting the environment, stirring the paint evenly, and avoiding splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

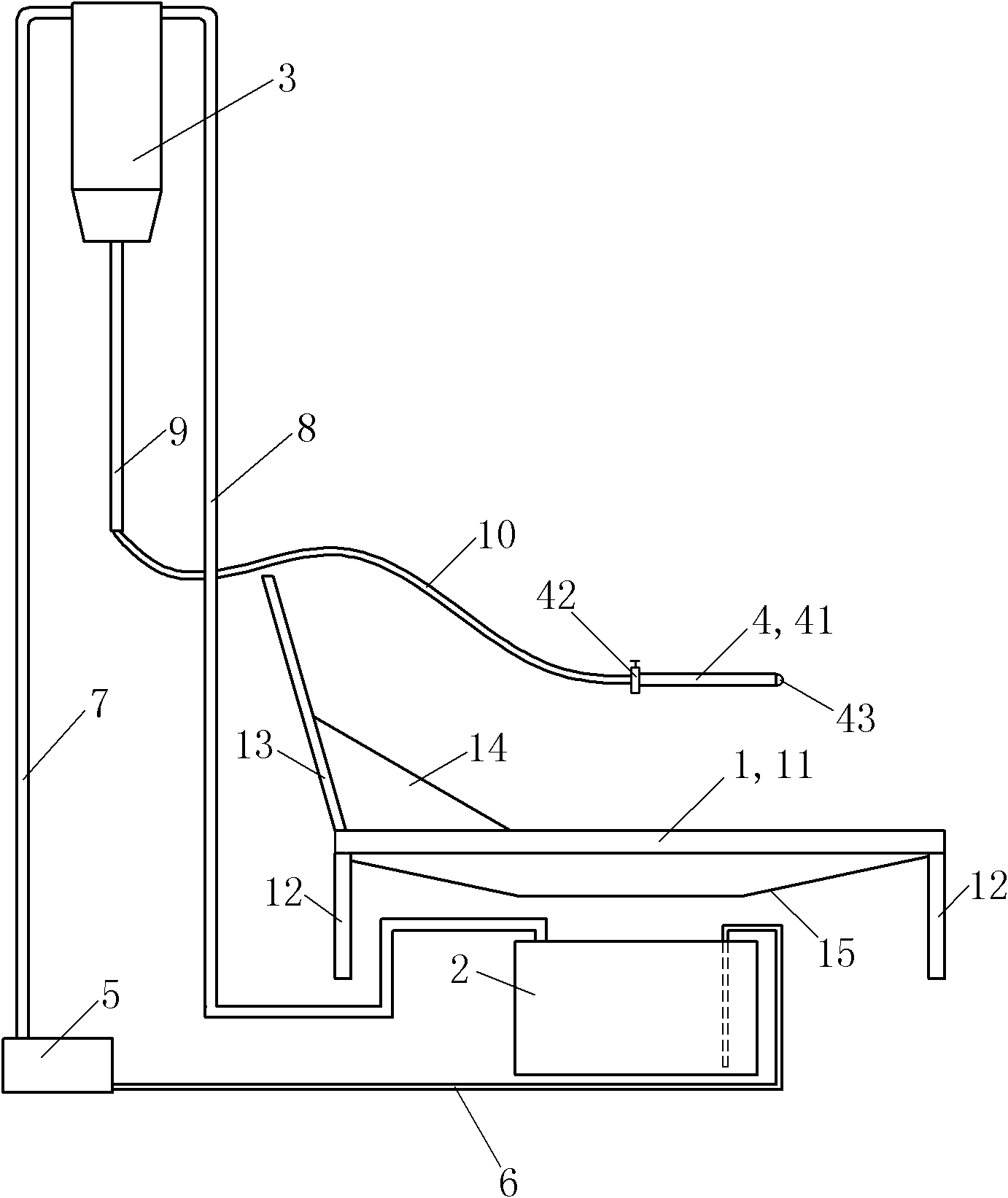

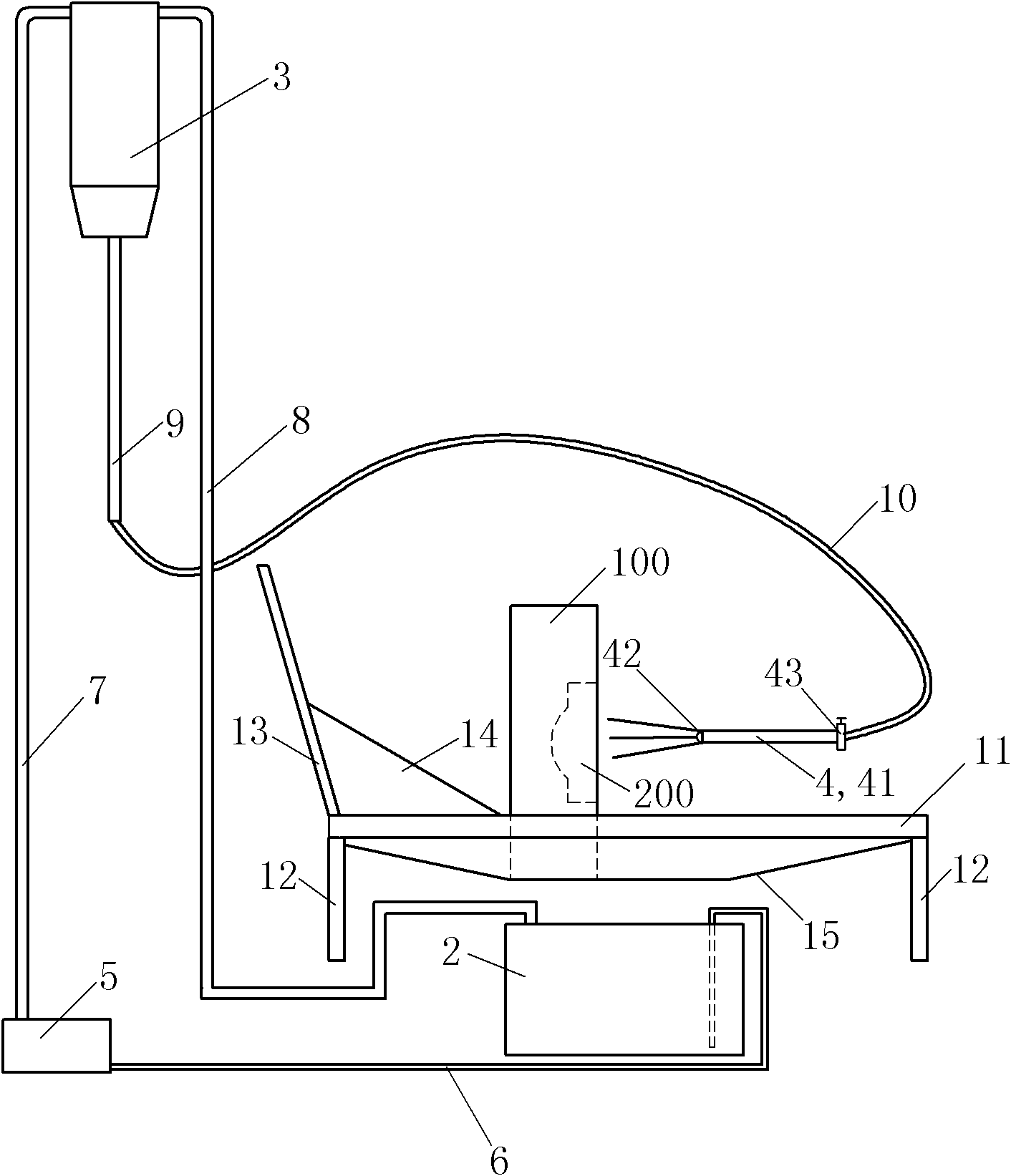

[0025] See figure 1 , the mold paint spraying device of the present embodiment comprises a spray pool 1, a material storage tank 2, a blanking tank 3, a spray rod 4, a slurry pump 5, a first conveying pipe 6, a second conveying pipe 7, a third Delivery pipe 8 , fourth delivery pipe 9 and hose 10 . The bottom of the blanking barrel 3 has a central hole. The blanking bucket 3 is fixed on a high place by a corresponding support (not shown in the figure).

[0026] The spray pool 1 includes a frame 11 , a column 12 , a baffle 13 , a side plate 14 and a lower cover 15 . The frame 11 and the four uprights 12 together constitute the skeleton of the spray pool 1 . The frame 11 is a rectangular frame, and there are four uprights 12. The upper ends of the four uprights 12 are all welded and fixed on the frame 11 from below, and are respectively located on the four corners of the frame 11, and the lower ends of the uprights are located on the ground. The baffle plate 13 is arranged ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com