Short-flow preparation process for thick-wall ring piece and thick-wall tube piece

A preparation process and short process technology, applied in the field of high-end equipment manufacturing, can solve the problems of many manufacturing processes and long production cycle, and achieve the effect of long manufacturing cycle, many heating times and reducing heating times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

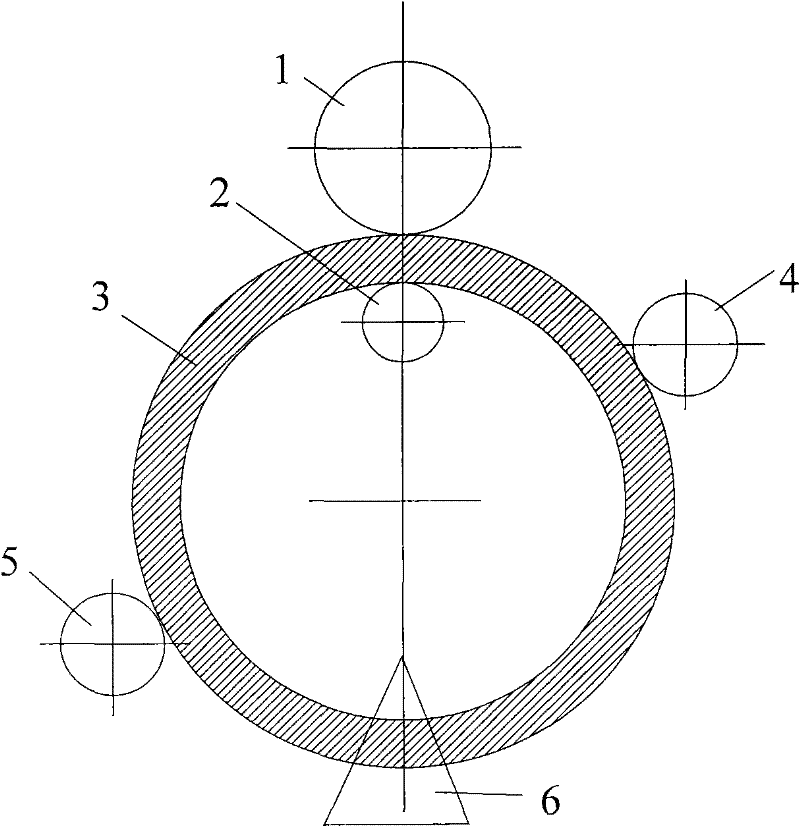

[0034] 1. Preparation of continuous casting hollow billet

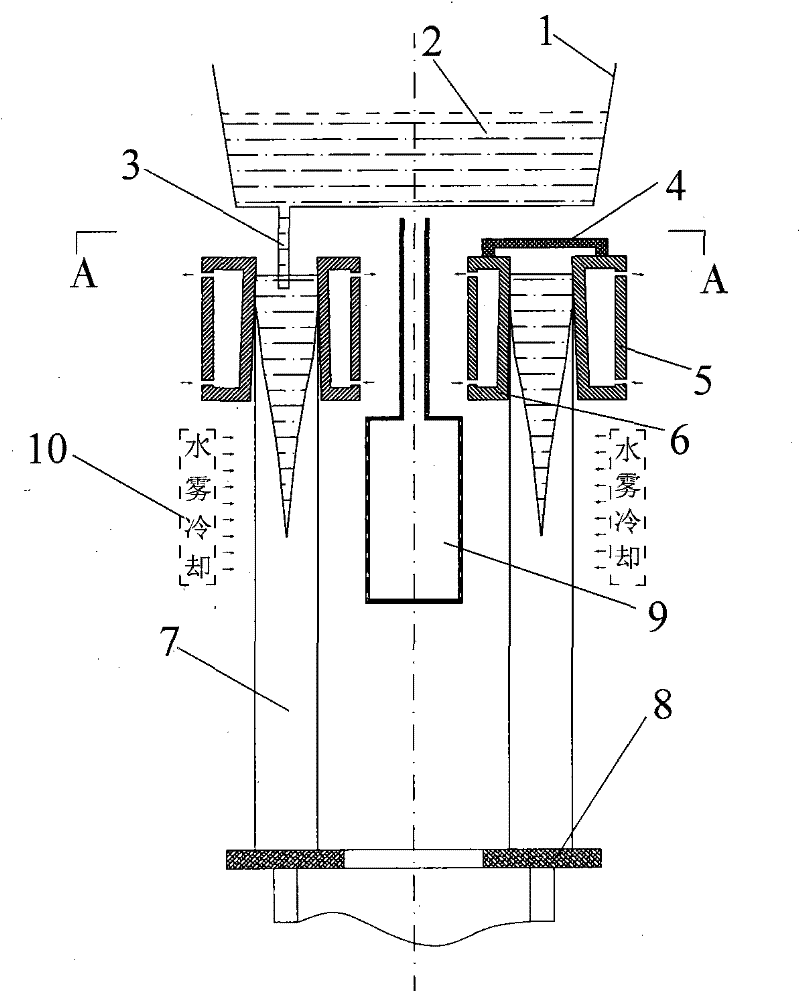

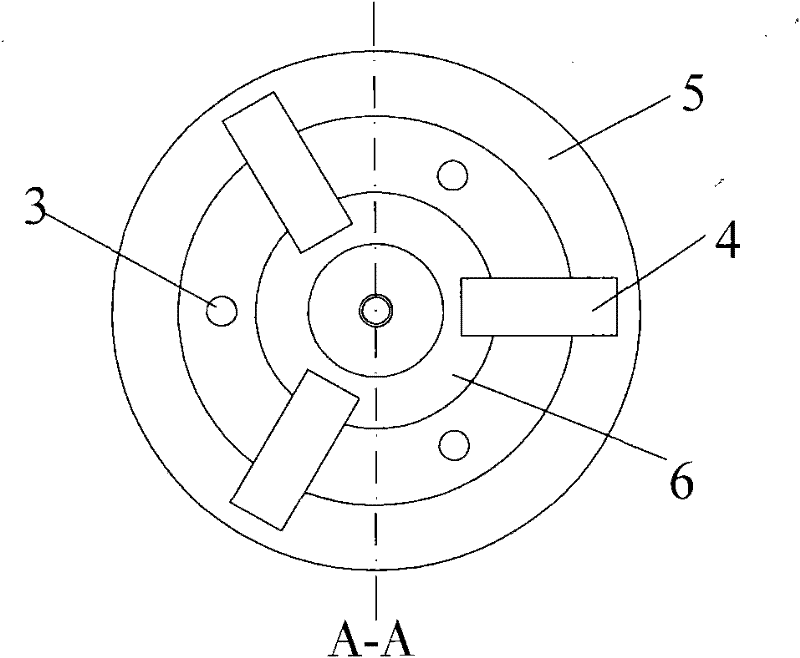

[0035] As shown in Figure 1(a)-(b), the hollow billet continuous casting equipment of the present invention mainly includes: a bottom drain ladle 1, molten metal 2, submerged nozzle 3, inner and outer mold connecting bridge 4, outer mold 5, inner mold Crystallizer 6, hollow billet 7, dummy bottom plate 8, core cooling device 9 and water mist cooling device 10, etc., the specific structure is as follows:

[0036] The bottom of the bottom drain ladle 1 is provided with at least one submerged nozzle 3 (three evenly distributed in this embodiment), the submerged nozzle 3 extends into the annular cavity formed between the inner mold 6 and the outer mold 5, and the inner crystallizer The crystallizer 6 and the external crystallizer 5 are connected through the connecting bridge 4 between the internal and external crystallizers. The molten metal 2 is poured at multiple points by using the submerged nozzle. The annular cavity...

Embodiment 1

[0048] Material: Q345E;

[0049] Hollow continuous casting slab inner diameter: 500mm;

[0050] Outer diameter of hollow continuous casting slab: 1200mm;

[0051] Hollow continuous casting slab cutting length: 215mm.

[0052] On the forging press, the above blanks are axially compressed to about 150mm, and the hollow continuous casting blanks are axially thickened to increase the compression ratio in the forming process of thick-walled ring parts. The forging ratio is 4.5.

[0053] Then carry out radial reaming and axial edge fixing on the prefabricated hollow billet on the ring rolling machine to produce ring flange parts for wind towers. The finished size of the ring parts is as follows:

[0054] Flange outer diameter: 4500mm;

[0055] Flange wall thickness: 100mm;

[0056] Flange height: 140mm;

[0057] Total weight of the flange: 2200kg.

Embodiment 2

[0059] Material: 508III;

[0060] Hollow continuous casting slab inner diameter: 1000mm;

[0061] Outer diameter of hollow continuous casting slab: 2000mm;

[0062] Hollow continuous casting slab cutting length: 2000mm.;

[0063] Radial reaming and axial elongation are carried out on the above blank on the forging press to produce the nuclear power evaporator cylinder. The dimensions of the finished cylinder are as follows:

[0064] Cylinder outer diameter: 4600mm;

[0065] Cylinder wall thickness: 165mm;

[0066] Cylinder height: 3600mm;

[0067] The total weight of the cylinder: 32000kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com