Device and method for processing large-breadth light guide plate

A light guide plate, large format technology, applied in metal processing equipment, optics, light guide and other directions, can solve the problems of limited speed and poor processing efficiency, and achieve the effects of high processing efficiency, improved yield and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention uses high-speed optical scanning galvanometer, CO 2 Lasers and a motion processing platform enable the etching process. In this process, the optical scanning device drives the reflective lens (very light, about 100 grams), and the laser is reflected by the lens to form a laser movement, so the movement speed can be greatly improved, which is many times higher than the overall speed of the traditional movement platform. This process method does not use non-corrosive acid for processing, has no toxicity caused by ink, can reach 100% yield, and has high processing efficiency (1 minute / piece).

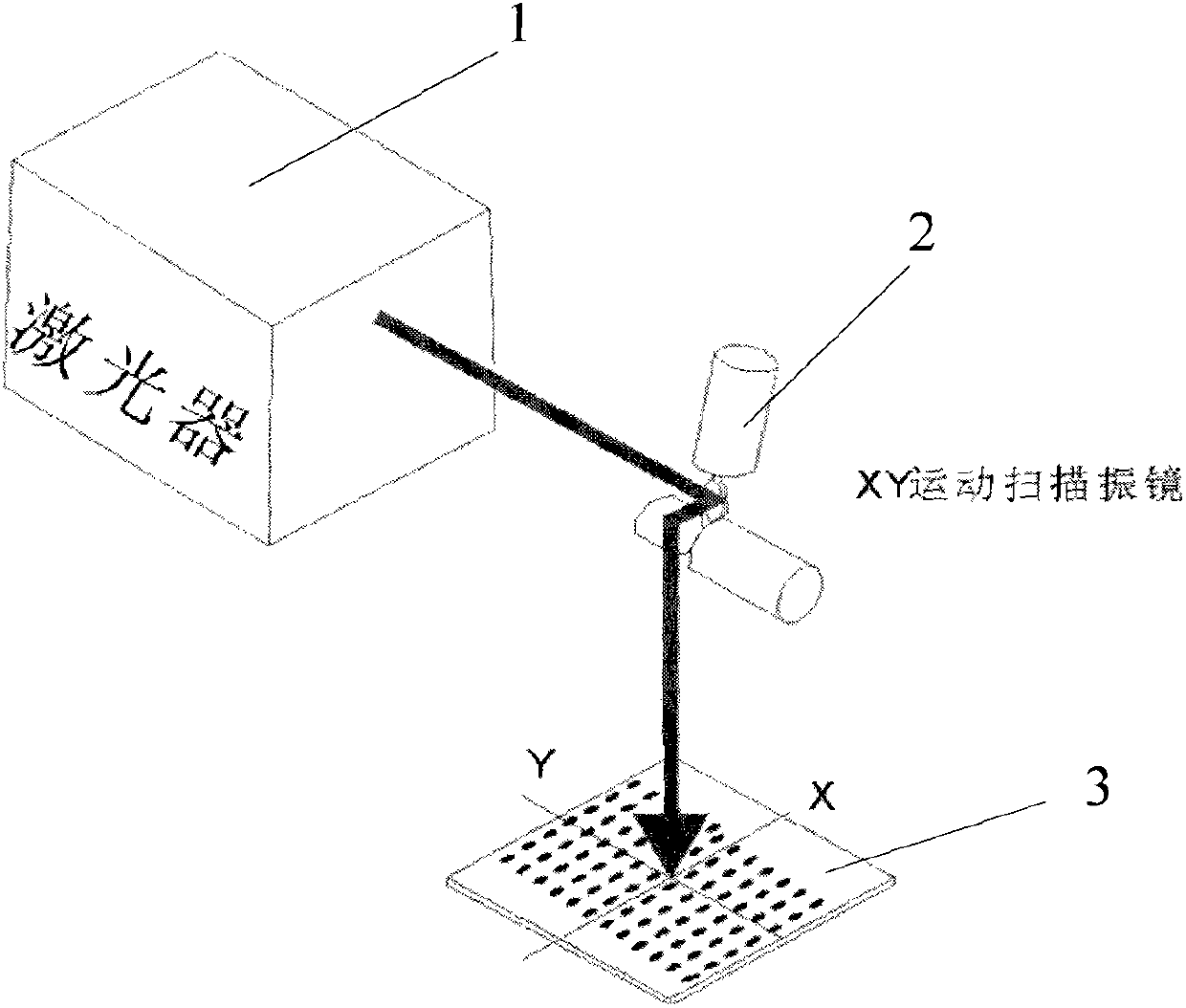

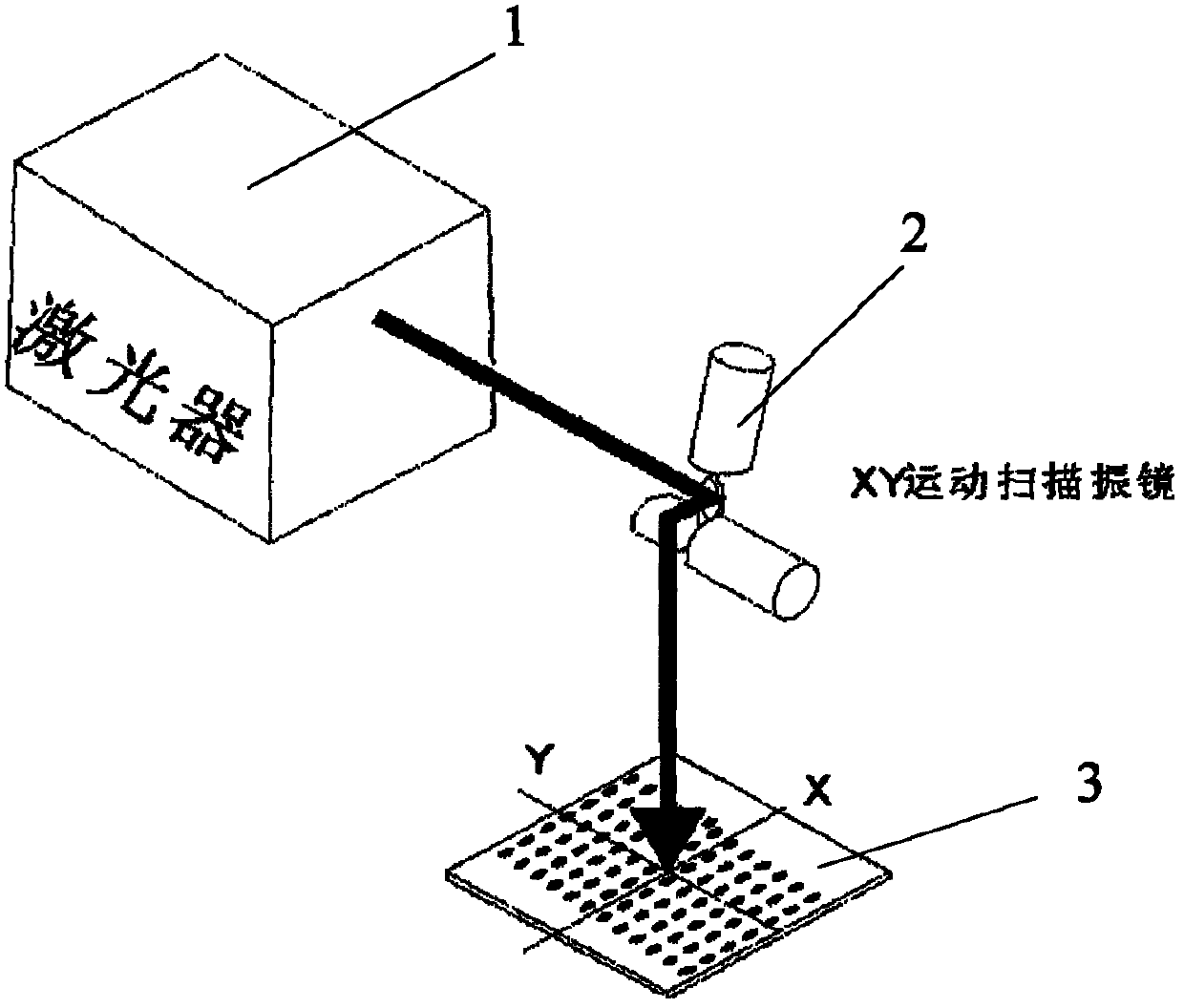

[0023] Such as figure 1 As shown, the device used to process large-format light guide plates, including CO 2 Laser 1, multi-dimensional motion scanning galvanometer 2 and motion working platform 3, CO 2 Laser 1 is CO with a wavelength of 10.6 μm 2 laser, CO 2 The output end of the laser 1 is provided with a multi-dimensional motion scanning galvanometer 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com