Production process of large-calibre epoxy glass fiber and braided strap winding extrusion draw pipe

A technology of epoxy glass fiber and production process, which is applied in the field of extruded pipe manufacturing, can solve the problem of inability to produce epoxy glass fiber extruded pipes with larger diameters, affecting the promotion and application range of extruded pipes, and the stress of epoxy resin. It can reduce the risk of enterprise operation, improve the torsion and splitting strength, and expand the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

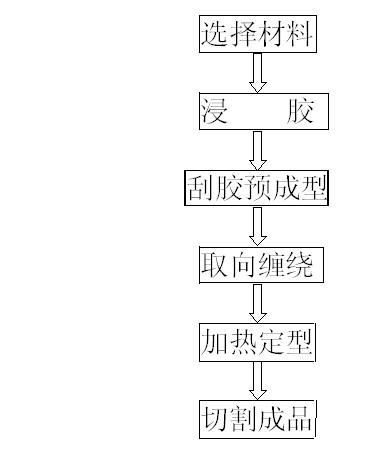

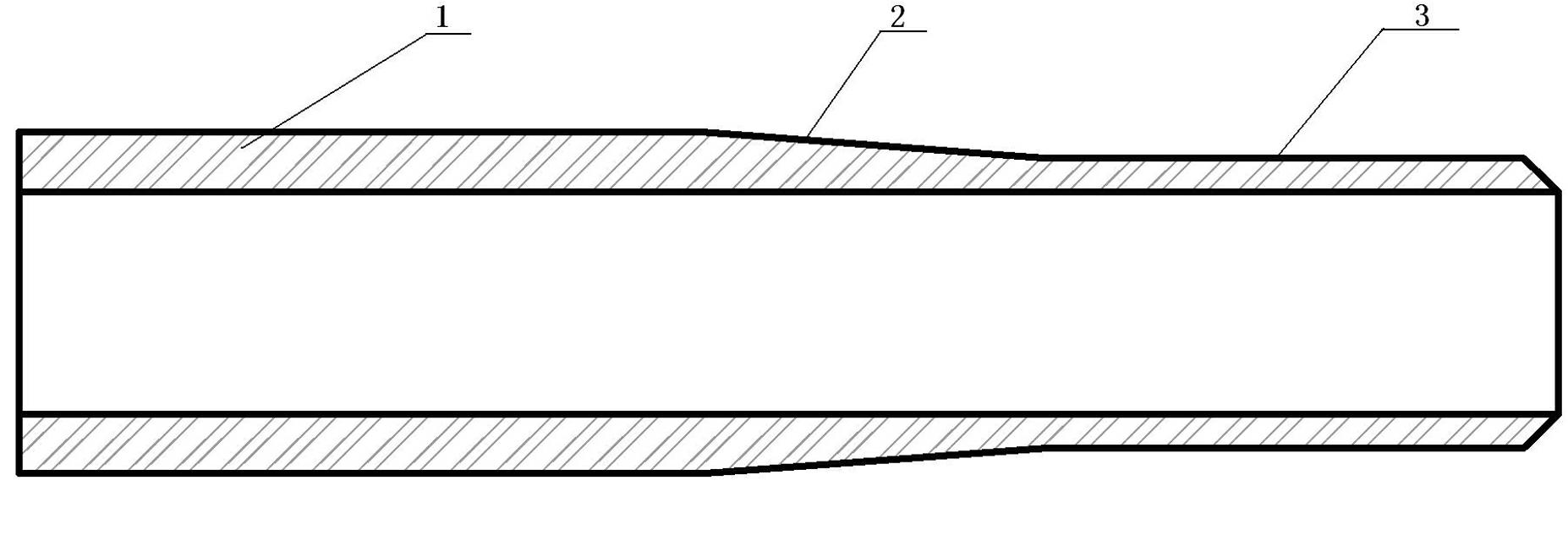

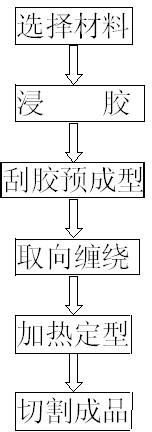

[0024] see figure 1 , the present embodiment is to provide a kind of high tensile strength, which can produce large-diameter epoxy glass fiber and ribbon winding extrusion tube production process. Taking tube drawing as an example, the process steps are as follows:

[0025] (1) Select materials; choose epoxy glass fiber filaments, epoxy resin, and glass filament braids as materials, orientate and distribute the glass fiber filaments and glass filament braids to form long fibers, and pass through the yarn splitter and winder.

[0026] In the long fiber component, the fiber content is 75-83%, and the resin content is 17-25%. Through this component, the comprehensive mechanical strength of the epoxy glass fiber extruded tube is increased. The long fiber content in this embodiment is 80%, and the resin content is 19%.

[0027] (2) Glue dipping; the long fibers in step (1) are evenly divided into several bundles of long fibers through the first yarn splitter, and then placed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com