Adhesive binder and preparation method thereof, composition, method for manufacturing adhesive binder layer and optical member

A technology of adhesives and compositions, applied in the direction of adhesives, polarizing elements, adhesive types, etc., can solve problems such as long curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

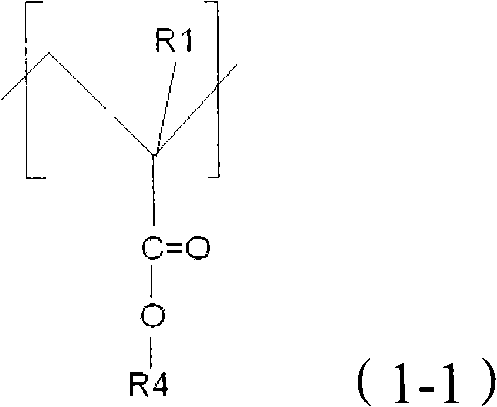

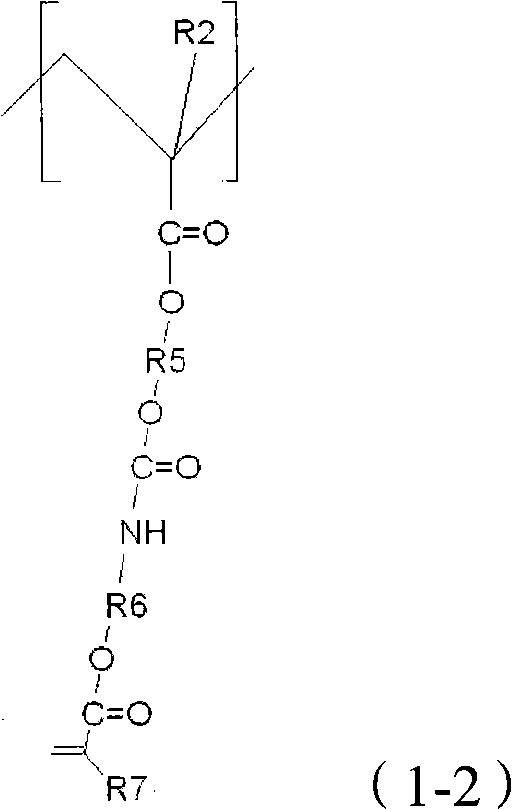

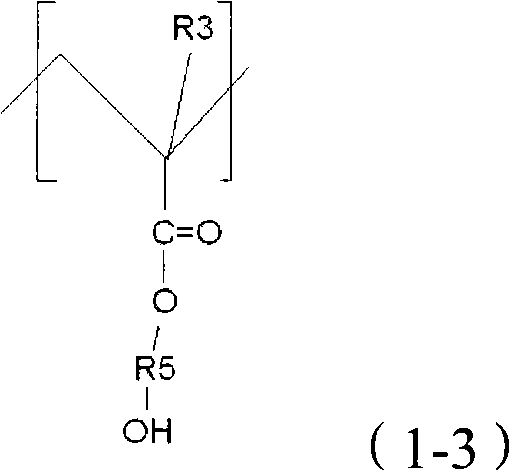

Method used

Image

Examples

preparation example 1

[0091] Preparation Example 1: Preparation of Adhesive A

[0092] 60 g of ethyl acetate was put into a 1-liter four-necked flask, and then 84 g of butyl acrylate, 10 g of benzyl methacrylate, and 4 g of 4-hydroxybutyl acrylate were added thereto. After heating to 70°C, 0.08 g of initiator (Vazo-52, DuPont) and 20 g of ethyl acetate were added. The mixture was kept for 3 hours. To this mixture was added 320 g of ethyl acetate. After cooling to 40° C., 2 g of 2-isocyanoethyl methacrylate and 0.01 g of DBTDL were added as catalysts. The resulting mixture was reacted for 12 hours. Nitrogen was fed to the flask at a rate of 10 cc / min throughout the reaction. The polymerized product was found to have a viscosity of 4000 to 10000 cps at 25°C and a solids content of 20%.

preparation example 2

[0093] Preparation Example 2: Preparation of Adhesive B

[0094] The procedure of Preparation Example 1 was repeated except that butyl acrylate, benzyl methacrylate, 4-hydroxybutyl acrylate, and 2-isocyanoethyl methacrylate were used in amounts of 81 g, 15 g, 3 g, and 1 g, respectively.

preparation example 3

[0095] Preparation Example 3: Preparation of Adhesive C

[0096] The procedure of Preparation 1 was repeated except that butyl acrylate, benzyl methacrylate, and 4-hydroxybutyl acrylate were used in amounts of 86 g, 10 g, and 4 g, respectively, instead of 2-isocyanoethyl methacrylate .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com